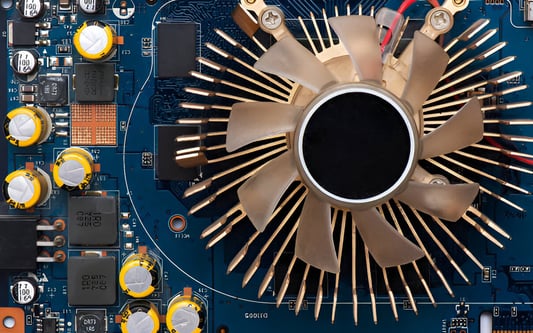

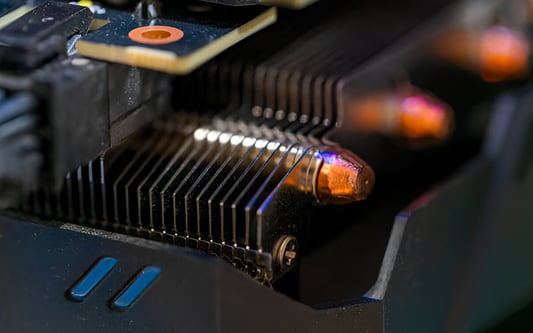

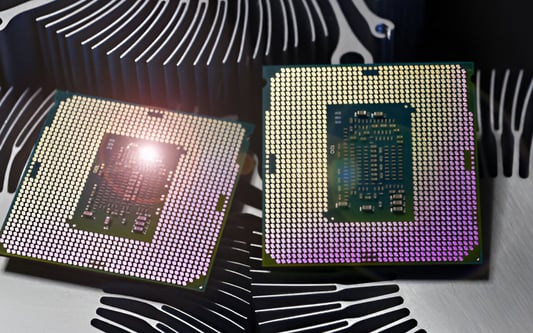

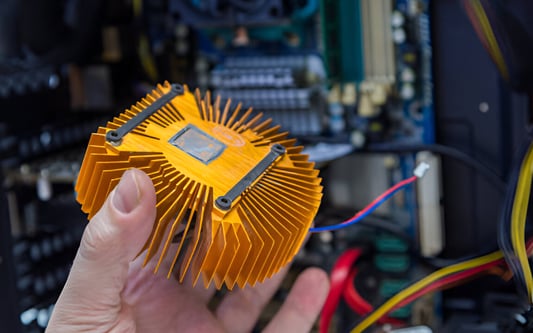

Is aluminium good for a heat sink??Heat sinks play a crucial role in dissipating the heat produced by electronic devices. Making one out of the right material can make all the difference. Aluminium is often a popular choice due to its lightweight and excellent thermal conductivity, but is it good enough for a heat sink? Let's find out.What is a Heat Sink?A heat sink is a passive device that absorbs and dissipates heat produced by an electronic device. It uses a combination of materials, surface area and volume to transfer the heat to the surrounding environment. Heat sinks are used to regulate the temperature of electronic devices and prevent overheating.Why is Aluminium a Popular Choice for Heat Sinks?Aluminium's thermal conductivity is the primary reason why it is a popular choice for heat sinks. It is an excellent conductor of heat, with a thermal conductivity of 238 W/mK. Additionally, aluminium is lightweight, readily available and relatively inexpensive compared to other materials like copper.Does Aluminium Make a Good Heat Sink?Yes, aluminium makes for a good heat sink. It is an excellent thermal conductor, lightweight and easy to work with. However, for high-power applications or situations where weight is not a significant issue, other materials like copper, silver or diamond may be a better choice.Advantages of Aluminium Heat SinksUsing aluminium in heat sinks comes with a host of advantages. Firstly, aluminium is lighter than other materials like copper or silver, which is useful in applications where weight is critical. Furthermore, aluminium is corrosion-resistant, meaning that it can stand up to harsh environments without degrading over time. Finally, aluminium is an excellent thermal conductor, allowing it to transfer heat effectively.Disadvantages of Aluminium Heat SinksWhile aluminium is an excellent material for heat sinks, it is not the perfect material. Aluminium has a lower thermal conductivity than other materials like copper or diamond, which means that it may not be as effective in dissipating heat. Additionally, the lightweight nature of aluminium can make it less effective in high-power applications where a more substantial material is needed.When Should You Consider Using Aluminium Heat Sinks?Aluminium heat sinks are best suited for applications where weight is a critical factor. They are ideal for low-power devices that do not produce a lot of heat, like LEDs or small electronics. Furthermore, aluminium heat sinks are appropriate for applications where cost is a primary concern, as aluminium is relatively inexpensive compared to other materials.When Should You Consider Using Other Materials?Other materials like copper, silver or diamond are better suited for high-power applications or situations where weight is not a significant concern. Copper and silver have a higher thermal conductivity than aluminium, while diamond is an excellent heat conductor and can handle extreme temperatures. These materials are also more expensive than aluminium, making them less suitable for low-cost applications.ConclusionAluminium is a good choice for heat sinks in many applications. It is lightweight, easy to work with, corrosion-resistant and an excellent thermal conductor. However, for high-power applications or situations where weight is not a concern, other materials like copper, silver or diamond may be a better choice. If you are unsure which material to use for your heat sink, consult with a professional to determine the most suitable material for your application.Aluminium heat sink, thermal conductivity, dissipating heat, electronic devices, copper, silver, diamond, lightweightIs Aluminium Good for a Heat Sink?- Pros and Cons of Using AluminiumDiscover the pros and cons of using aluminium for a heat sink. Understand the thermal conductivity of aluminium and when it is suitable to use for your electronic devices. Quote InquiryContact us