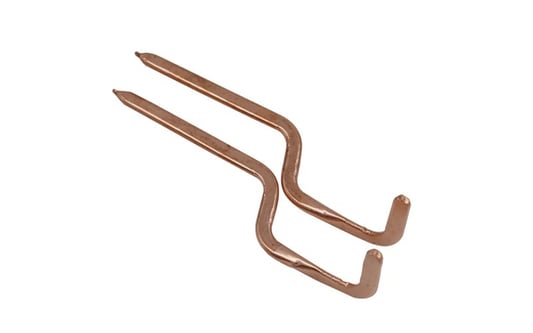

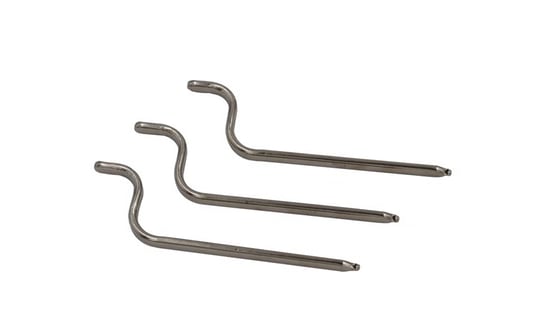

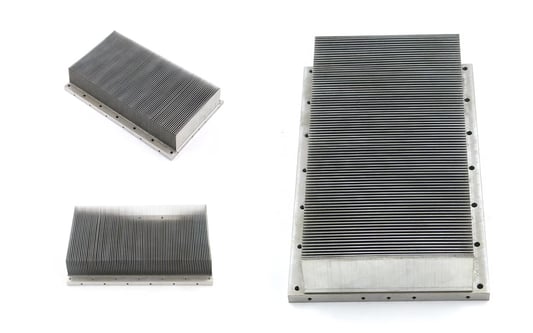

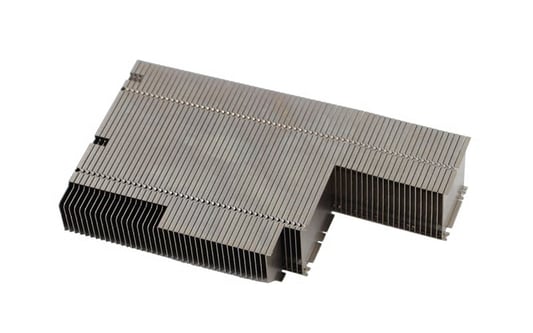

Introduction to Heat PipesHeat pipes are highly efficient heat transfer devices that are extensively used in various industrial applications. They are capable of transferring large amounts of heat with minimal temperature difference. Heat pipes come in different types, each with its own unique characteristics and applications.Working Principle of Heat PipesHeat pipes work on the principle of phase change heat transfer. A working fluid inside the heat pipe absorbs heat at the evaporator section, where it evaporates and travels to the condenser section. At the condenser, the vapor condenses and releases the heat, and the liquid is then returned to the evaporator by capillary action.Types of Heat Pipes1. Vapor Chamber Heat Pipes Vapor chamber heat pipes are two-dimensional heat pipes that are commonly used in applications such as CPUs, GPUs, and LED lighting. They offer excellent thermal performance and are ideal for high-power electronic devices. 2. Grooved Heat Pipes Grooved heat pipes have internal grooves that enhance capillary action, allowing them to work efficiently against gravity. They are used in applications where heat needs to be transferred over long distances or across uneven surfaces. 3. Loop Heat Pipes Loop heat pipes are a variation of heat pipes that utilize a wick structure and a secondary loop to manage the circulation of the working fluid. They are commonly used in spacecraft thermal control systems due to their high efficiency and reliability.Industrial Applications of Heat Pipes1. Electronics Cooling Heat pipes are commonly used for cooling electronic devices such as CPUs, GPUs, and servers. They help dissipate heat efficiently, ensuring optimal performance and longevity of the electronic components. 2. Aerospace Industry In the aerospace industry, heat pipes are used for thermal management in spacecraft, satellites, and aircraft. They help regulate temperatures in extreme conditions and prevent overheating of critical components. 3. Energy Systems Heat pipes play a crucial role in energy systems such as solar thermal power plants and geothermal energy systems. They help transfer heat from the heat source to the power generation unit, maximizing efficiency and performance.Advantages of Using Heat Pipes1. High Heat Transfer Efficiency Heat pipes offer high heat transfer efficiency compared to traditional heat transfer methods, making them a cost-effective solution for various industrial applications. 2. Passive Operation Heat pipes operate passively, requiring no external power source or moving parts. This ensures reliability and reduces maintenance requirements, making them ideal for long-term use. 3. Compact Design Heat pipes have a compact and lightweight design, making them easy to integrate into existing systems without adding significant bulk or weight. This is especially beneficial in space-constrained applications.Challenges and LimitationsWhile heat pipes offer numerous advantages, they also have some limitations. Challenges such as temperature limitations, compatibility with different working fluids, and reliability issues in harsh environments need to be addressed for optimal performance.Future Trends in Heat Pipe TechnologyAdvancements in material science, manufacturing techniques, and design optimization are driving the evolution of heat pipe technology. Future trends include the development of high-temperature heat pipes, integration of advanced materials, and customization for specific industrial applications.ConclusionHeat pipes are versatile heat transfer devices with a wide range of industrial applications. Understanding the different types of heat pipes and their unique characteristics can help in selecting the right heat pipe for specific heating and cooling requirements. With ongoing advancements in heat pipe technology, the potential for more efficient and innovative heat transfer solutions in various industries is limitless.Quote Inquirycontact us