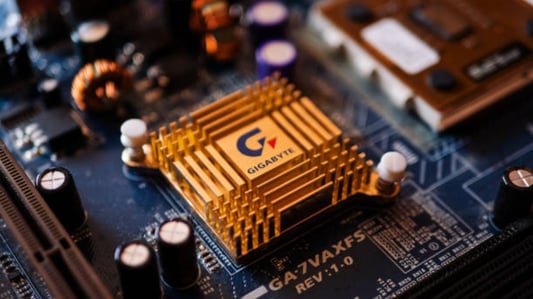

Introduction to Heat Sink MaterialsWhen it comes to heat sinks, the material used plays a crucial role in determining its effectiveness. The right material can greatly enhance heat dissipation and improve overall performance. Different materials have different thermal conductivity and specific heat capacity properties, making some more suitable for heat sink applications than others.Aluminum: Lightweight and EfficientAluminum is one of the most commonly used materials for heat sinks due to its lightweight nature and excellent thermal conductivity. It is also cost-effective, making it a popular choice for many applications. Aluminum heat sinks are easy to manufacture and can be customized to fit specific requirements.Copper: High Thermal ConductivityCopper is another popular choice for heat sink materials because of its high thermal conductivity. Copper heat sinks are very efficient at dissipating heat, making them ideal for high-performance applications. However, copper is heavier and more expensive than aluminum, which can be a drawback for some projects.Graphite: Lightweight and VersatileGraphite is a lightweight material with high thermal conductivity, making it an excellent choice for heat sinks. Graphite heat sinks can be designed in various shapes and sizes, offering versatility in applications where space is limited. They are also resistant to corrosion and do not require surface treatment.Composite Materials: Combining StrengthsSome heat sinks are made from composite materials, combining the strengths of different elements to create an optimal solution. By combining materials like aluminum and copper, manufacturers can create heat sinks that offer a balance of thermal conductivity, weight, and cost-effectiveness. Composite materials are a popular choice for custom heat sink designs.Heat Pipes: Efficient Heat TransferHeat pipes are another innovative solution for heat sink materials, offering efficient heat transfer capabilities. These pipes are filled with a working fluid that evaporates at the heat source and condenses at the heat sink, transferring thermal energy effectively. Heat pipes are especially useful in applications where traditional heat sinks may not be suitable.Thermal Interface Materials: Enhancing PerformanceIn addition to the material used for the heat sink itself, thermal interface materials play a critical role in enhancing heat transfer. These materials are placed between the heat sink and the heat source to improve thermal conductivity and reduce air gaps. Common thermal interface materials include thermal pads, thermal paste, and thermal adhesives.Anodization and Plating: Surface TreatmentsSurface treatments like anodization and plating can further enhance the performance of heat sink materials. Anodization creates a protective oxide layer on aluminum surfaces, improving corrosion resistance and heat dissipation. Plating with materials like nickel or gold can also enhance thermal conductivity and provide a more aesthetically pleasing finish.Environmental Considerations: Durability and SustainabilityWhen selecting a material for a heat sink, it is important to consider environmental factors such as durability and sustainability. Choosing materials that are recyclable and environmentally friendly can help reduce the overall impact of heat sink manufacturing and disposal. Aluminum and copper are both highly recyclable materials, making them environmentally conscious choices.Conclusion: Choosing the Right MaterialIn conclusion, the material used for a heat sink is a critical factor in determining its performance and efficiency. Aluminum, copper, graphite, and composite materials are all excellent choices for heat sink applications, offering a balance of thermal conductivity, weight, and cost. By considering factors such as thermal properties, manufacturing ease, and environmental impact, engineers can select the right material to optimize heat sink performance in their applications.Quote InquiryContact us!