What is an aluminium sheet heat sink and How Does It Work?

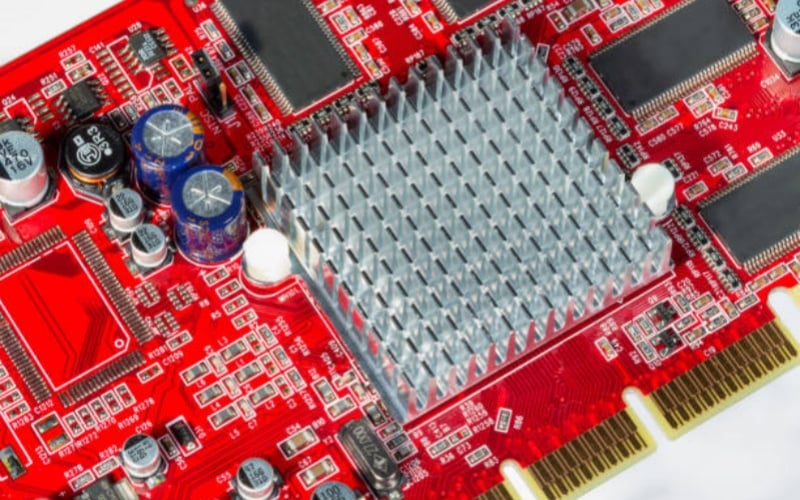

Aluminium sheet heat sink is a crucial component in electronic devices and other heat-generating equipment. A heat sink is a passive cooling mechanism that transfers heat generated by a device to the surrounding environment. Aluminium sheet heat sinks are designed to dissipate the heat from electronic components such as CPUs and GPUs. They draw the heat away from the device and then transfer it to the fins or other extended surfaces to increase the surface area. As the surface area increases, the heat dissipates faster into the air and cools the device down.

Advantages of Aluminium Sheet Heat Sink

Aluminium sheet heat sinks are gaining popularity over other heat sink materials such as copper or iron. Here are some of the advantages of using aluminium sheet as a heat sink material:

- Lightweight: Aluminium is a lighter metal than copper or iron, making it easy to handle and install.

- Good thermal conductivity: Aluminium has an excellent thermal conductivity, making it an ideal heat transfer material.

- Corrosion-resistant: Aluminium can resist corrosion from environmental factors such as water or air, making it a good choice for a long-lasting heat sink.

- Cost-effective: Aluminium is more affordable than other heat sink materials, making it a budget-friendly option.

Aluminium Sheet Heat Sink Design

The design of aluminium sheet heat sinks is critical for their effectiveness and efficiency. There are three primary design factors to consider for optimal heat dissipation: shape, size, and material.

Shape:

The shape of the heat sink plays a significant role in heat dissipation. The most common shapes of heat sinks are rectangular and square. However, other shapes such as circular or hexagonal can also work well. The critical factor is to maximize the surface area of the heat sink to increase the contact between the heat sink and the surrounding airflow.

Size:

The size of the heat sink is determined by the size of the device it is designed to cool. A larger device will require a larger heat sink to dissipate the heat efficiently. The size of the heat sink should also consider the fin density and spacing to ensure optimal airflow for heat dissipation.

Material:

The material used in the heat sink affects its overall efficiency. Aluminium is an excellent heat transfer material, making it an ideal choice for the heat sink. However, the use of other materials such as copper or graphite can also work well depending on the specific application.

Manufacturing Process for Aluminium Sheet Heat Sink

The manufacturing process of aluminium sheet heat sinks involves the following steps:

- I. Material selection: High-quality aluminium sheets are selected for their thermal conductivity and corrosion resistance.

- II. Cutting and shaping: The selected sheets are cut and shaped into the desired size and shape of the heat sink. The process can be done using shearing, sawing, or laser cutting.

- III. Finishing: The heat sink surface is finished to improve its thermal conductivity and corrosion resistance. The finishing process can include anodizing or chemical etching.

- IV: Assembly: The heat sink is assembled with the device it is designed to cool down.

Applications of Aluminium Sheet Heat Sink

Aluminium sheet heat sinks have a wide range of applications in various industrial sectors. Here are some of the typical applications of aluminium sheet heat sink:

- Computers: Aluminium sheet heat sinks are commonly used in CPUs and GPUs to prevent overheating.

- LED lighting and display panels: High-powered LED lights and displays generate a lot of heat and require efficient heat dissipation mechanisms to prevent damage to the device.

- Automobiles: Electronic components in modern cars generate a significant amount of heat, which requires an efficient cooling mechanism such as an aluminium sheet heat sink.

- Solar panels: Solar panels generate heat during operation, which can reduce their effectiveness. An aluminium sheet heat sink can dissipate the heat, thus improving their efficiency.

Aluminium sheet heat sink is an essential component in electronic devices and other equipment that generates heat. It is a cost-effective and lightweight material that offers excellent thermal conductivity properties. The design of aluminium sheet heat sinks plays a significant role in their overall efficiency, which is why it's essential to consider factors such as shape, size, and material. By choosing the right design and manufacturing process for your aluminium sheet heat sink, you can ensure optimal heat dissipation and improve the longevity of your device.