The Basics of Cold Plate Technology

Cold plates are widely used in various industries for cooling electronic components, power electronics, lasers, medical equipment, and other heat-generating devices. They provide an efficient and reliable means of dissipating heat and maintaining optimal operating temperatures. In this article, we will explore the principle of cold plate technology and its applications.

Understanding Cold Plate Operation

The principle of a cold plate revolves around the concept of heat transfer through a combination of conduction, convection, and sometimes phase change mechanisms. The device typically consists of a metal plate or multiple plates with channels or grooves for the circulation of a cooling fluid.

Conduction: The Foundation of Cold Plate Cooling

Conduction is the primary method of heat transfer in cold plates. The heat generated by the electronic component is conducted through the solid material of the plate. Metals with high thermal conductivity, such as copper and aluminum, are commonly used for cold plates to ensure efficient heat transfer.

Convection: Enhancing Heat Dissipation

Convection is the process of transferring heat between a solid surface and a moving fluid, such as air or a liquid. In cold plates, the cooling fluid flowing through the channels or grooves absorbs heat from the plate's surface and carries it away. This continuous flow of the cooling fluid ensures efficient dissipation of heat.

Phase Change Cooling: Going Beyond Conduction and Convection

In some advanced cold plate designs, phase change cooling mechanisms are employed to further enhance heat dissipation. This involves circulating a cooling fluid that undergoes a phase change, such as from liquid to vapor or vice versa, to absorb and release large amounts of heat. Phase change cooling is particularly effective for high-power applications that require exceptional cooling performance.

Types of Cold Plates

Cold plates come in various configurations to suit different cooling requirements. Some common types include:

1. Liquid Cold Plates:

These cold plates use a liquid coolant, such as water or a water-glycol mixture, to transfer heat. They are highly efficient and can handle high heat loads, making them suitable for demanding applications.

2. Air-Cooled Cold Plates:

These cold plates use forced air to remove heat from the plate's surface. They are typically used in applications where liquid cooling is not feasible or practical.

3. Hybrid Cold Plates:

These cold plates combine both liquid and air cooling methods to achieve optimal heat dissipation. They provide versatility and can be customized for specific cooling requirements.

Applications of Cold Plates

Cold plates find wide-ranging applications in various industries. Some notable examples include:

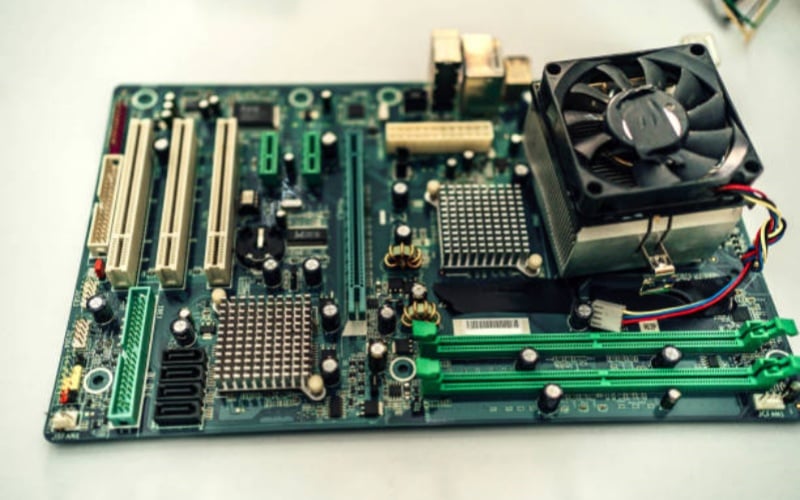

1. Electronics Cooling:

Cold plates are extensively used to cool electronic components, such as CPUs, power modules, IGBTs, and RF amplifiers. They help maintain optimal operating temperatures, improving overall performance and reliability.

2. Medical Equipment:

Cold plates are used in medical equipment like MRI machines and laser systems to dissipate heat generated by the equipment. This ensures stable operation and extends the lifespan of critical components.

3. Aerospace and Defense:

Cold plates are employed in avionics systems, radar equipment, and electronic warfare systems to prevent overheating and ensure reliable operation in demanding environments.

4. Energy Storage:

Cold plates play a crucial role in cooling batteries and energy storage systems, preventing thermal runaway and maintaining optimal performance.

5. Automotive:

In the automotive industry, cold plates are used for cooling electric vehicle batteries, power electronics, and onboard charging systems.

In Conclusion

Cold plates are essential components in various industries and applications where efficient heat dissipation is crucial. By leveraging conduction, convection, and sometimes phase change cooling mechanisms, these plates effectively maintain optimal operating temperatures and enhance overall performance and reliability.