Understanding the Basics of Heat Sink Extrusion

Heat sink extrusion is a process used to manufacture heat sinks, which are essential for dissipating heat from electronic devices. This process involves creating heat sinks by forcing aluminum or other metal alloys through a die to achieve the desired shape and dimensions.

The Importance of Thermal Management

Effective thermal management is crucial for preventing electronic components from overheating. Heat sinks play a vital role in this process by transferring heat away from the electronic components and dissipating it into the surrounding environment.

Benefits of Aluminum in Heat Sink Extrusion

Aluminum is the most commonly used material in heat sink extrusion due to its excellent thermal conductivity and lightweight properties. It allows for efficient heat transfer while keeping the overall weight of the heat sink to a minimum.

The Extrusion Process Explained

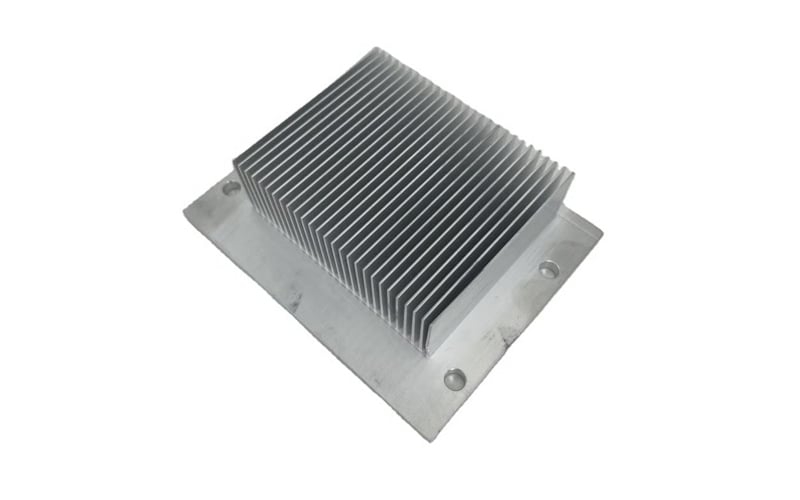

During the heat sink extrusion process, aluminum billets are heated to a specific temperature and then forced through a shaped opening in a die using a hydraulic press. This results in the creation of a heat sink with intricate fin patterns that maximize surface area for heat dissipation.

Customization Options for Heat Sinks

One of the key advantages of the extrusion process is the ability to customize heat sinks to meet specific design requirements. Manufacturers can create heat sinks in various shapes, sizes, and configurations to suit the needs of different electronic devices.

Surface Treatments for Enhanced Performance

To improve the thermal performance of heat sinks, manufacturers often apply surface treatments such as anodizing or powder coating. These treatments not only enhance the appearance of the heat sink but also provide additional protection against corrosion.

Quality Control in Heat Sink Extrusion

Ensuring the quality of heat sinks is essential to their performance and longevity. Manufacturers employ stringent quality control measures throughout the extrusion process to maintain consistency in dimensions and thermal conductivity.

Applications of Heat Sink Extrusion

Heat sink extrusion is widely used in various industries, including electronics, automotive, and aerospace. These heat sinks are vital components in electronic devices, LED lighting, power supplies, and other applications that require efficient heat dissipation.

Recent Advancements in Heat Sink Technology

With ongoing developments in material science and manufacturing technology, heat sink designs are constantly evolving. New materials and innovative manufacturing techniques are being explored to enhance the thermal efficiency of heat sinks.

Choosing the Right Heat Sink for Your Application

When selecting a heat sink for your electronic device, consider factors such as thermal resistance, airflow requirements, and space constraints. Working with a reputable manufacturer can help ensure that you get a heat sink that meets your specific needs.