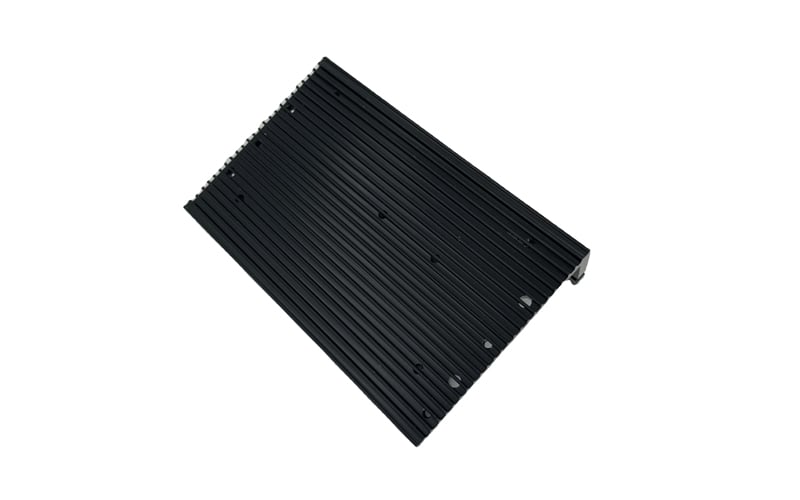

The Basics of extrusion heat sinks

Extrusion heat sinks are used in various industries to manage heat generated by electronic components. They are typically made of aluminum or copper and come in various shapes and sizes to suit different applications. The extrusion process helps to create complex heat sink designs with excellent thermal conductivity.

Benefits of Extrusion Heat Sinks

Extrusion heat sinks offer several benefits, including improved heat dissipation, increased efficiency, and reliability of electronic devices. They are lightweight, cost-effective, and easy to manufacture in large quantities. Additionally, extrusion heat sinks can be customized to meet specific design requirements.

Types of Extrusion Heat Sinks

There are various types of extrusion heat sinks, such as profiles, skived fins, and bonded fin heat sinks. Profiles are the most common type and are made by extruding aluminum or copper through a die to create the desired shape. Skived fins are produced by slicing a block of material and then folding the fins into place. Bonded fin heat sinks are made by attaching fins to a base using adhesive or solder.

Applications of Extrusion Heat Sinks

Extrusion heat sinks are widely used in electronics, telecommunications, automotive, and aerospace industries. They are commonly found in power supplies, LED lighting, computers, and audio amplifiers. Extrusion heat sinks are essential for maintaining optimal operating temperatures and extending the lifespan of electronic components.

Factors to Consider When Choosing Extrusion Heat Sinks

When selecting extrusion heat sinks for a specific application, it is essential to consider factors such as thermal resistance, mounting options, size constraints, and material selection. The thermal performance of the heat sink must match the heat dissipation requirements of the electronic device to prevent overheating.

Design Considerations for Extrusion Heat Sinks

Designing an effective extrusion heat sink involves optimizing the fin geometry, base thickness, and overall surface area for maximum heat transfer. The shape, size, and spacing of fins play a crucial role in improving thermal performance. Careful consideration must also be given to airflow and mounting orientation.

Installation of Extrusion Heat Sinks

Proper installation of extrusion heat sinks is crucial for ensuring optimal heat dissipation and device reliability. The heat sink should be securely mounted to the electronic component using thermal interface materials, such as thermal paste or pads, to minimize thermal resistance. Adequate airflow around the heat sink is also essential for efficient cooling.

Maintenance of Extrusion Heat Sinks

Regular maintenance of extrusion heat sinks is necessary to ensure continued performance and reliability. Cleaning the heat sink and removing dust and debris can help maintain proper airflow and prevent overheating. Inspecting the heat sink for signs of damage or corrosion is also essential for long-term functionality.

Advancements in Extrusion Heat Sink Technology

Recent advancements in extrusion heat sink technology have focused on improving thermal conductivity, reducing weight, and enhancing overall performance. Innovative designs, such as microchannel heat sinks and heat pipes, are being developed to meet the increasing thermal management demands of modern electronics.

Conclusion

Extrusion heat sinks play a vital role in managing heat generation in electronic devices and ensuring reliable performance. By understanding the basics, benefits, types, applications, and design considerations of extrusion heat sinks, engineers and designers can effectively incorporate them into their products for optimal thermal management.