Aluminum Heatsink Fins

Aluminum heatsink fins are the most common type of fins used in heatsinks. They are lightweight, cost-effective, and offer good thermal conductivity. The design of aluminum fins can vary, with options for straight fins, pin fins, and folded fins.

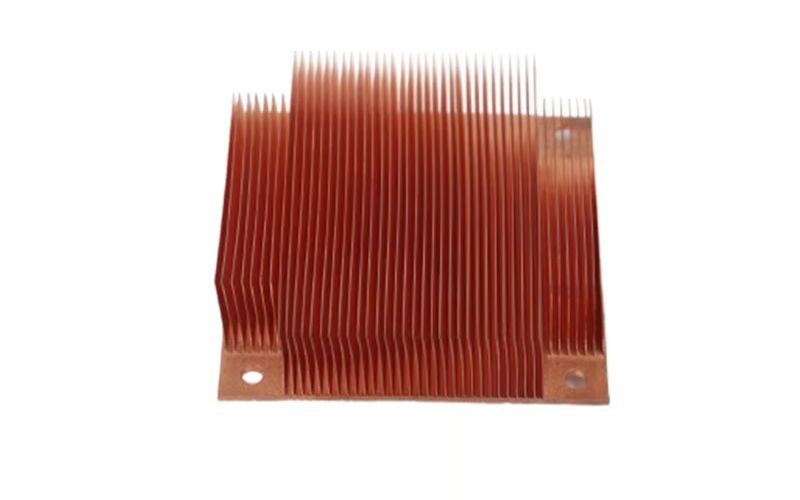

Copper Heatsink Fins

Copper heatsink fins are known for their superior thermal conductivity compared to aluminum fins. They are typically more expensive and heavier than aluminum fins, but they offer better heat dissipation capabilities. Copper fins are often used in high-performance heatsinks for applications requiring efficient cooling.

Nickel-plated Heatsink Fins

Nickel-plated heatsink fins combine the benefits of aluminum and copper fins. They offer decent thermal conductivity while providing corrosion resistance and durability. Nickel plating can also improve the appearance of the heatsink, making it a popular choice for consumer electronics.

Skived Heatsink Fins

Skived heatsink fins are produced by slicing a block of metal at an angle to create thin, slanted fins. This manufacturing process allows for increased surface area and better heat dissipation. Skived fins can be made from aluminum, copper, or other metals depending on the specific thermal requirements.

Extruded Heatsink Fins

Extruded heatsink fins are created by forcing metal through a die to produce fins with a consistent cross-sectional shape. This process allows for high-volume production of heatsinks with uniform fins. Extruded fins are commonly made from aluminum and are used in various electronic devices.

Pinned Heatsink Fins

Pinned heatsink fins are designed with pins that extend from the base of the heatsink to increase the surface area for heat dissipation. The pins create airflow channels between the fins, improving thermal performance. Pinned fins are often seen in high-power LED lights and computer processors.

Serrated Heatsink Fins

Serrated heatsink fins feature small cuts or serrations along the edges of the fins to enhance turbulence and promote better heat transfer. The serrations disrupt the airflow, increasing heat exchange efficiency. This design is commonly used in heatsinks for automotive cooling systems.

Folded Heatsink Fins

Folded heatsink fins are created by folding sheet metal to form a series of interconnected fins. This design increases the structural integrity of the heatsink while also maximizing the surface area for heat dissipation. Folded fins are often used in compact electronic devices where space is limited.

Dimpled Heatsink Fins

Dimpled heatsink fins feature small indentations on the surface of the fins to create turbulence and improve heat transfer. The dimples disrupt the laminar flow of air, increasing the convective heat transfer coefficient. Dimpled fins are commonly used in heatsinks for telecommunications equipment.

Ribbed Heatsink Fins

Ribbed heatsink fins have raised ribs or ridges along the surface of the fins to increase the surface area and enhance cooling efficiency. The ribbed design promotes better airflow and heat dissipation, making it suitable for high-temperature applications. Ribbed fins are often found in industrial heatsinks and power electronics.