What material is used for aluminum heat sinks??

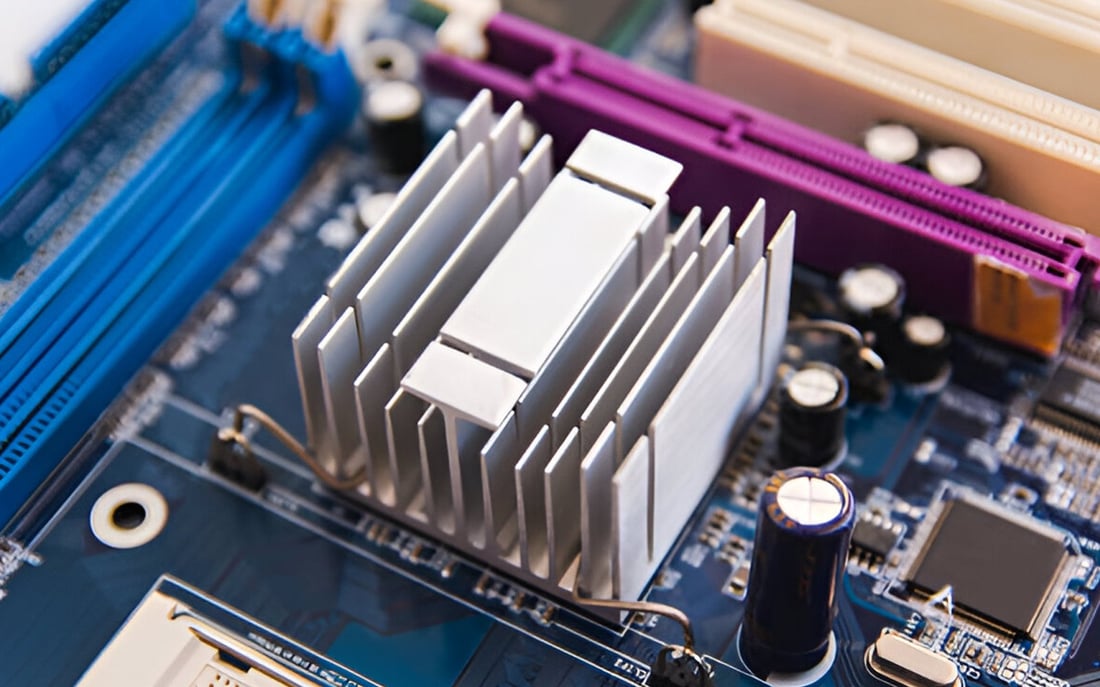

Heat sinks are components that help dissipate heat from electronic devices, such as computer CPUs and LED lights. One of the most used materials for making heat sinks is aluminum. But what makes aluminum such a popular choice for heat sinks? This article will explore the characteristics of aluminum that make it a suitable material for heat sinks.

High Thermal Conductivity

Thermal conductivity is the ability of a material to conduct heat. Aluminum has high thermal conductivity, which means it can quickly transfer heat from its source to the heat sink. This allows the heat sink to efficiently distribute the heat over a larger surface area, where it can dissipate into the air or a liquid coolant. Compared to other metals, such as copper, aluminum has lower thermal conductivity but it is more cost-effective and easier to shape.

Lightweight and Durable

Another advantage of using aluminum for heat sinks is its low weight and durability. Aluminum is a lightweight metal, which makes it easy to handle and transport. It is also resistant to corrosion and can withstand high temperatures. Aluminum heat sinks can last for long periods, even in harsh environments. They are also easy to manufacture and can be customized to fit different shapes and sizes.

Cost-Effective

The cost of producing aluminum heat sinks is relatively low when compared to other materials. Aluminum is abundant and easily available, which makes it cheaper than metals such as copper or silver. Furthermore, because aluminum is lightweight, shipping costs are lower, which further reduces the overall cost of production.

Good Electrical Conductivity

In addition to its thermal conductivity, aluminum has good electrical conductivity. This means that it can also act as a shield against electromagnetic interference (EMI). When electronic devices emit EMI, it can cause interference with other devices or systems. Aluminum heat sinks can act as a barrier, preventing EMI from escaping the device and affecting other equipment.

Easy to Fabricate

Aluminum is easy to shape and process, making it an ideal material for heat sinks. It can be easily formed into different shapes and sizes using various manufacturing techniques, such as extrusion and casting. This allows heat sinks to be customized to fit the specific requirements of different applications.

Low Density

Aluminum is one of the lightest metals, with a density of approximately one-third that of steel. This makes aluminum heat sinks ideal for applications where weight is a critical factor. For example, in aircraft and automotive industries, where fuel efficiency is needed, aluminum is an ideal choice for heat sinks because it helps reduce the weight of the vehicle without sacrificing performance.

Good Chemical Stability

Aluminum is resistant to chemical attacks from most substances. It does not easily corrode or react with acids, bases, or salts. This means that aluminum heat sinks are suitable for use in harsh environments where exposure to chemicals is common.

Easy to Clean

Another advantage of using aluminum for heat sinks is that it is easy to clean. Because it does not corrode easily, it can withstand frequent cleaning without affecting its performance. This is important for applications where high levels of hygiene are required, such as medical equipment, where heat sinks need to be cleaned regularly to prevent the spread of infections.

High Strength-to-Weight Ratio

Aluminum has a high strength-to-weight ratio, which means it is strong despite its low weight. The strength of aluminum heat sinks makes them capable of withstanding high mechanical loads while still maintaining their shape. This is important in applications where heat sinks are exposed to vibration, impact, or other mechanical stresses.

Recyclable

Finally, aluminum is a highly recyclable material, which makes it an eco-friendly choice for heat sinks. Unlike other metals, such as copper or silver, aluminum can be easily recycled without losing its properties. This means that end-of-life aluminum heat sinks can be recycled and used to make new products, reducing the amount of waste that goes into landfills.

Conclusion

Aluminum is one of the most widely used materials for heat sinks because of its high thermal and electrical conductivity, low weight, durability, low cost, ease of fabrication, chemical stability, and recyclability. These characteristics make it suitable for a wide range of applications, from computer hardware to LED lighting and automotive industry. As technology advances and the need for more efficient cooling increases, aluminum will likely remain a popular choice for heat sinks.