Introduction to Liquid Cold Plates

Liquid cold plates are commonly used in electronics cooling applications to dissipate heat efficiently. These plates contain channels through which a cooling liquid flows, effectively transferring heat away from sensitive components.

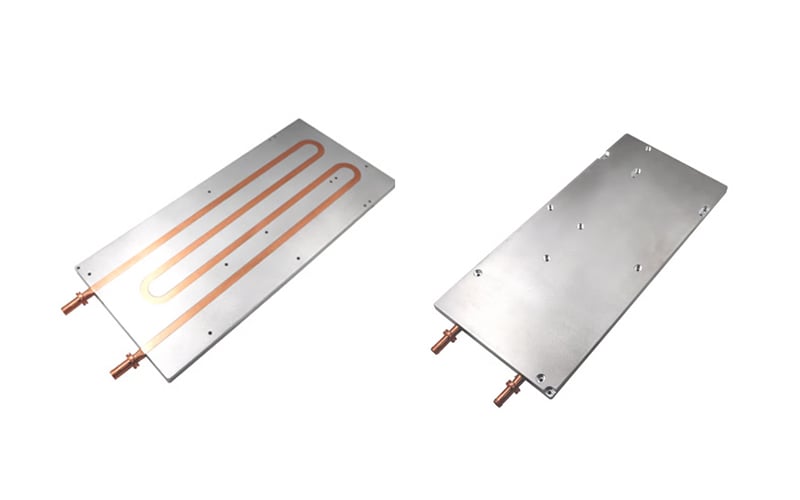

Precision Design and Manufacture

Advanced CNC machining techniques play a crucial role in the design and manufacture of liquid cold plates. These techniques allow for complex designs with tight tolerances to be realized, ensuring optimal performance and reliability.

Optimized Channel Geometry

One key aspect of CNC machining for liquid cold plates is the optimization of channel geometry. By using advanced machining techniques, manufacturers can create intricate channel designs that maximize heat transfer efficiency.

Material Selection for Enhanced Performance

The choice of material for liquid cold plates is critical to their performance. Advanced CNC machining techniques allow for the use of a wide range of materials, including aluminum, copper, and stainless steel, each offering unique benefits for heat dissipation.

Surface Finishing for Improved Heat Transfer

Surface finishing is another important aspect of CNC machining for liquid cold plates. By carefully controlling surface roughness and texture, manufacturers can enhance heat transfer capabilities, ensuring optimal performance under various operating conditions.

Integration of Thermal Management Features

Incorporating thermal management features such as fins, turbulators, and manifolds is made possible through advanced CNC machining techniques. These features help to further enhance heat dissipation and overall efficiency of liquid cold plates.

Tight Quality Control Standards

Manufacturers of liquid cold plates rely on advanced CNC machining to maintain tight quality control standards. Each plate must undergo rigorous inspection processes to ensure dimensional accuracy, surface finish, and overall performance.

Customization for Specific Applications

One of the key advantages of advanced CNC machining techniques is the ability to customize liquid cold plates for specific applications. Manufacturers can tailor designs to meet the exact requirements of their customers, ensuring optimal performance.

Efficient Production Processes

Advanced CNC machining allows for efficient production processes, reducing lead times and costs associated with manufacturing liquid cold plates. This streamlined approach ensures timely delivery without sacrificing quality.

Future Trends in CNC Machining for Liquid Cold Plates

As technology continues to advance, we can expect to see further innovations in CNC machining techniques for liquid cold plates. Enhanced automation, improved material selection, and advanced cooling designs are just some of the developments on the horizon.