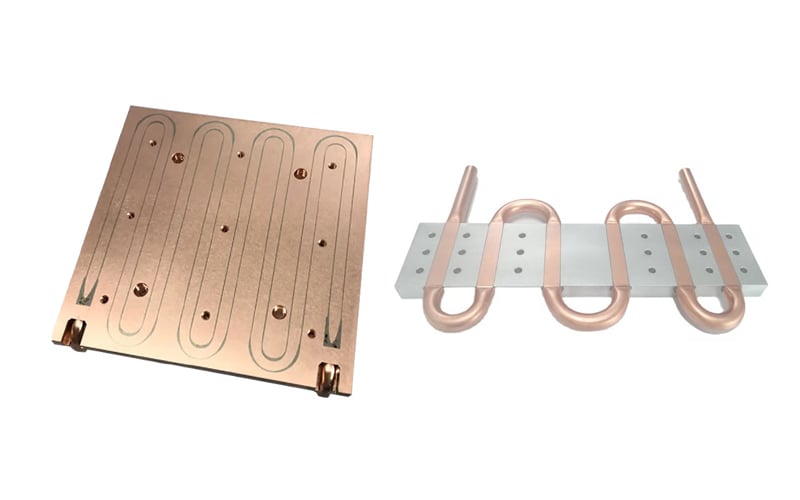

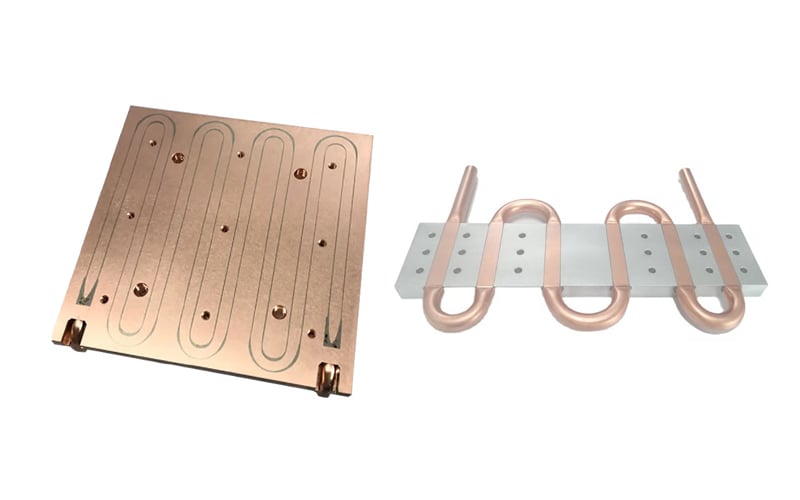

Liquid cold plates are commonly used in electronic devices to dissipate heat generated during operation. Performance testing standards ensure that these cold plates meet specified performance criteria.

Definition and Purpose of Liquid Cold Plate Performance Testing Standards

Liquid cold plate performance testing standards define the testing procedures and criteria used to evaluate the thermal performance of liquid cold plates. These standards ensure that cold plates meet specific performance requirements set by manufacturers and regulatory bodies.

Key Parameters for Liquid Cold Plate Performance Testing

Some key parameters that are typically evaluated during liquid cold plate performance testing include thermal resistance, pressure drop, and heat dissipation capacity. These parameters help determine the effectiveness of a cold plate in cooling electronic components.

Methods Used for Liquid Cold Plate Performance Testing

Common methods used for liquid cold plate performance testing include thermal resistance testing, pressure drop testing, and heat transfer coefficient testing. These methods help assess the thermal performance and efficiency of cold plates under various operating conditions.

Importance of Standardized Testing Procedures

Standardized testing procedures are essential to ensure consistency and reliability in evaluating the performance of liquid cold plates. By following standardized testing protocols, manufacturers can accurately compare the performance of different cold plate designs.

Regulatory Compliance and Certification

Adherence to liquid cold plate performance testing standards is crucial for regulatory compliance and certification. Meeting these standards ensures that cold plates meet the required performance specifications and operate safely within specified temperature limits.

Advancements in Testing Technology

Advancements in testing technology have led to the development of more sophisticated testing equipment and techniques for evaluating liquid cold plate performance. These advancements allow for more precise and accurate measurements of thermal performance parameters.

Benefits of Conforming to Performance Testing Standards

Conforming to liquid cold plate performance testing standards helps manufacturers demonstrate the quality and reliability of their products. It also provides assurance to customers that the cold plates they are using meet industry-recognized performance benchmarks.

Future Trends in Liquid Cold Plate Performance Testing

As electronic devices become more advanced and compact, the demand for efficient thermal management solutions like liquid cold plates is expected to increase. This trend will drive further development of performance testing standards to ensure the optimal performance of these cooling technologies.

Conclusion

In conclusion, liquid cold plate performance testing standards play a crucial role in ensuring the reliability and efficiency of thermal management solutions for electronic devices. By adhering to these standards, manufacturers can deliver high-quality cold plates that meet the evolving needs of the electronics industry.

Quote Inquiry

contact us