Overview of Compact Liquid Cold Plate Designs

Compact liquid cold plate designs are essential components in space-limited applications where efficient heat dissipation is crucial. These innovative solutions provide a compact and lightweight alternative to traditional heat sinks, making them ideal for aerospace, automotive, and industrial applications.

Benefits of Using Compact Liquid Cold Plates

One of the key benefits of compact liquid cold plates is their high thermal conductivity, which allows for efficient heat transfer and dissipation. Additionally, these designs offer a more uniform cooling effect compared to air-cooled solutions, resulting in improved overall system performance and reliability.

Design Considerations for Space-Limited Applications

When designing compact liquid cold plates for space-limited applications, engineers must consider factors such as size, weight, and thermal performance. By utilizing advanced materials and innovative manufacturing techniques, designers can create highly efficient cooling solutions that meet the specific requirements of the application.

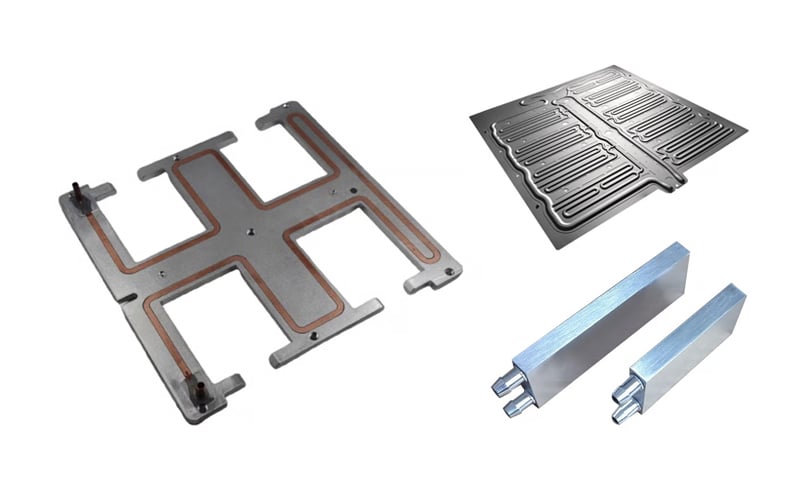

Materials Used in Compact Liquid Cold Plate Designs

Common materials used in compact liquid cold plate designs include aluminum, copper, and stainless steel, each offering unique advantages in terms of thermal conductivity and corrosion resistance. By selecting the appropriate material for the application, engineers can optimize the performance and longevity of the cold plate design.

Integration of Compact Liquid Cold Plates in Electronics Cooling

In electronics cooling applications, compact liquid cold plates play a crucial role in dissipating heat generated by high-power components such as CPUs, GPUs, and power amplifiers. By integrating these cold plates into the cooling system, engineers can effectively manage thermal loads and ensure reliable operation of electronic devices.

Advancements in Compact Liquid Cold Plate Technology

Recent advancements in compact liquid cold plate technology have led to the development of more efficient and cost-effective designs. By incorporating features such as microchannels, enhanced surface coatings, and advanced manufacturing processes, engineers can further improve the performance and reliability of these cooling solutions.

Efficiency and Performance of Compact Liquid Cold Plates

Compact liquid cold plates offer superior thermal performance and efficiency compared to traditional cooling solutions, making them ideal for space-limited applications where size and weight are critical factors. By maximizing heat transfer capabilities and minimizing pressure drop, these cold plates can effectively dissipate heat while maintaining compact dimensions.

Applications of Compact Liquid Cold Plate Designs

Compact liquid cold plate designs are widely used in a variety of industries, including aerospace, automotive, telecommunications, and renewable energy. These versatile cooling solutions are suitable for applications where space is limited and efficient thermal management is essential for optimal performance.

Future Trends in Compact Liquid Cold Plate Designs

As technology continues to evolve, we can expect to see further advancements in compact liquid cold plate designs, including the development of more compact and lightweight solutions with enhanced thermal performance. By staying at the forefront of innovation, engineers can continue to push the boundaries of cooling technology in space-limited applications.

Conclusion

Compact liquid cold plate designs offer a highly efficient and reliable cooling solution for space-limited applications where traditional heat sinks may not be practical. By considering design factors, material selection, and integration strategies, engineers can create innovative cold plate solutions that meet the specific requirements of each application, ensuring optimal performance and system reliability.