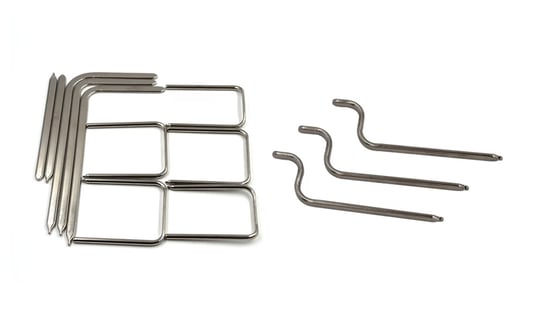

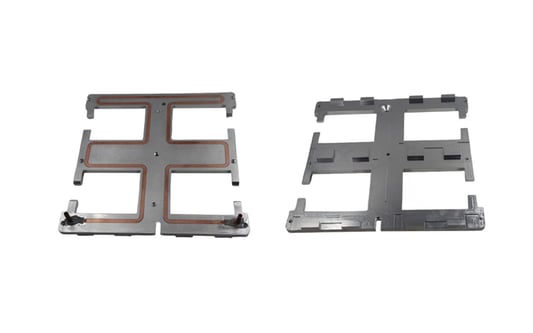

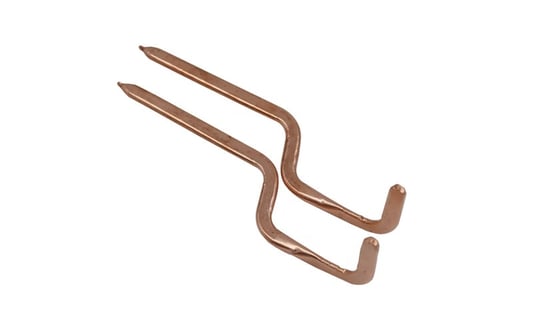

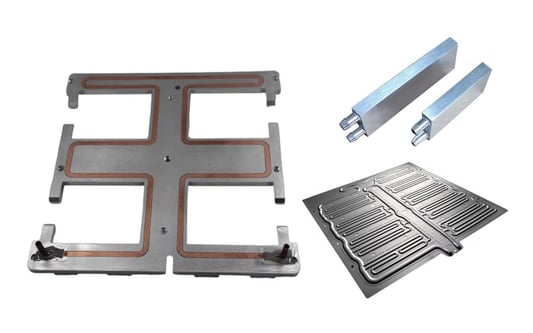

Efficient Heat DissipationHeat sinks for pipes play a crucial role in industrial applications by efficiently dissipating heat generated during various processes. By providing a larger surface area, heat sinks help in transferring heat away from the pipe, ensuring optimal performance and preventing overheating.Increased DurabilityOne of the key benefits of using heat sinks for pipes is increased durability. By maintaining the pipe's temperature within a safe operating range, heat sinks help in preventing thermal fatigue and prolonging the lifespan of the pipe, ultimately reducing maintenance costs.Improved Energy EfficiencyHeat sinks for pipes can also contribute to improved energy efficiency by reducing the amount of heat lost during the transfer process. By effectively managing heat dissipation, heat sinks help in conserving energy and lowering operating costs in industrial settings.Enhanced PerformanceThe use of heat sinks for pipes can significantly enhance the overall performance of industrial systems. By keeping the pipe's temperature under control, heat sinks help in maximizing the system's efficiency and productivity, leading to better output quality.Thermal ManagementProper thermal management is essential in industrial settings to prevent equipment failure and ensure operational stability. Heat sinks for pipes play a critical role in thermal management by regulating the temperature of the pipe, reducing the risk of overheating and potential damage.Compatibility with Various Pipe MaterialsHeat sinks for pipes are designed to be compatible with a wide range of pipe materials, including metals, plastics, and composite materials. This versatility makes heat sinks suitable for diverse industrial applications where heat dissipation is a concern.Easy Installation and MaintenanceHeat sinks for pipes are relatively easy to install and maintain, making them a cost-effective solution for industrial facilities. With simple mounting options and minimal upkeep requirements, heat sinks offer a hassle-free way to improve thermal management.Customized Designs for Specific RequirementsManufacturers offer customized heat sink designs tailored to meet specific requirements of industrial applications. Whether it's size, shape, or material compatibility, custom heat sinks ensure optimal heat dissipation and thermal performance for pipes in various settings.Enhanced Safety MeasuresBy preventing excessive heat build-up in pipes, heat sinks play a crucial role in enhancing safety measures in industrial environments. Maintaining proper thermal conditions not only protects equipment but also reduces the risk of workplace accidents and potential hazards.Cost-Effective SolutionInvesting in heat sinks for pipes is a cost-effective solution for improving thermal management in industrial settings. By preventing overheating, reducing maintenance costs, and enhancing energy efficiency, heat sinks offer long-term savings and operational benefits for businesses.Quote InquiryContact us