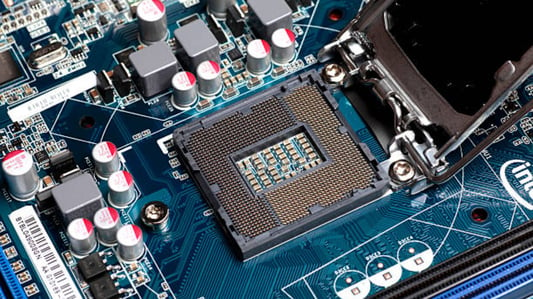

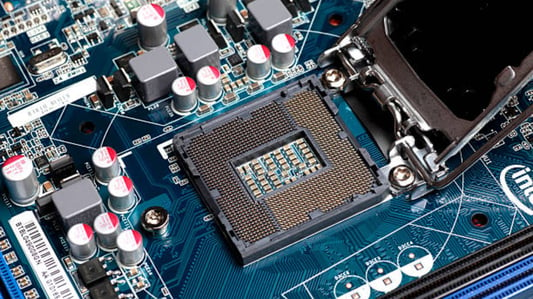

Introduction to Heat Sinks Heat sinks are essential components in electronic devices that help dissipate heat generated by electronic components such as CPUs, GPUs, and power transistors. They are designed to absorb and transfer heat away from the electronic components to prevent overheating and ensure optimal performance.Types of Heat Sinks There are various types of heat sinks available, including passive heat sinks, active heat sinks, and liquid-cooled heat sinks. Passive heat sinks rely on natural convection to dissipate heat, while active heat sinks use fans to enhance heat dissipation. Liquid-cooled heat sinks utilize coolant to effectively remove heat from the electronic components.Attachment Methods Heat sinks are typically attached to electronic components using thermal interface materials such as thermal paste, thermal pads, or phase-change materials. These materials help improve heat transfer between the heat sink and the electronic component, maximizing heat dissipation efficiency.Mounting Brackets Mounting brackets are commonly used to secure heat sinks to electronic components. These brackets provide stability and ensure that the heat sink remains in direct contact with the electronic component to facilitate optimal heat transfer.Spring Clips Spring clips are another popular attachment method for heat sinks. These clips apply consistent pressure to maintain contact between the heat sink and the electronic component, ensuring efficient heat dissipation.Screws and Bolts Screws and bolts are often used to secure heat sinks in place. They provide a more permanent attachment method compared to spring clips and mounting brackets, ensuring that the heat sink remains securely in position.Adhesive Tape Adhesive tape can be used to attach heat sinks to electronic components, providing a simple and convenient attachment method. However, it is important to ensure that the adhesive tape is capable of withstanding high temperatures to prevent detachment.Clips and Retention Modules Clips and retention modules are commonly used in conjunction with mounting brackets to secure heat sinks in place. These components provide additional support and ensure that the heat sink does not shift or become loose during operation.Custom Mounting Solutions In some cases, custom mounting solutions may be required to attach heat sinks to unique electronic components or configurations. These solutions are tailored to specific requirements and ensure that the heat sink is securely attached for optimal heat dissipation.Regular Maintenance It is important to regularly inspect and maintain the attachment of heat sinks to electronic components. Loose or improperly attached heat sinks can lead to decreased heat dissipation efficiency and potentially cause overheating issues in electronic devices.Quote InquiryContact us!