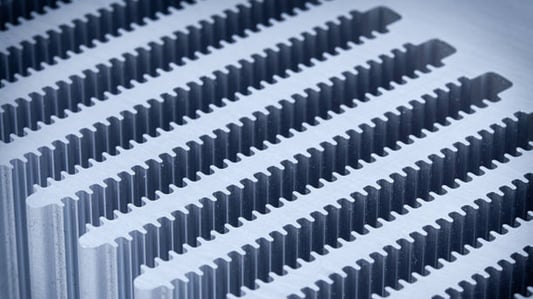

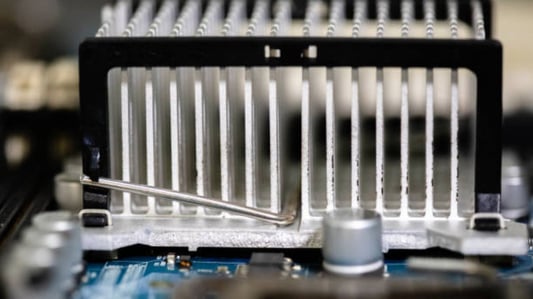

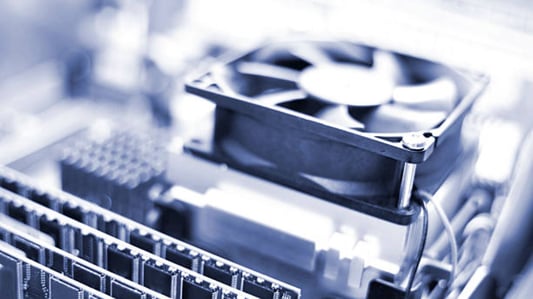

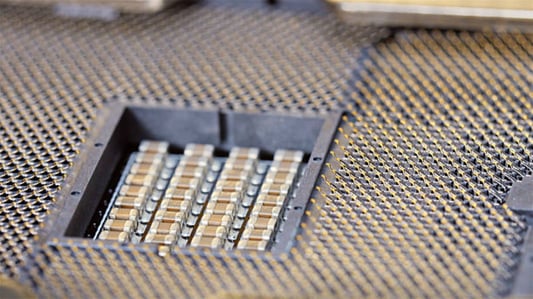

When it comes to heat sinks, manufacturers have a range of options to choose from depending on the application's requirements. Two of the most popular types of heat sinks are skived and extruded. In this article, we'll explore the differences between these two types of heat sinks and consider their benefits and drawbacks.1. What are Skived Heat Sinks?Skived heat sinks, also known as folded-fin heat sinks or cold-forged heat sinks, are made by slicing a block of aluminum into thin, flat plates that are then bent, folded, and bonded together to form the desired shape and size.2. What are Extruded Heat Sinks?Extruded heat sinks, on the other hand, are made using an extrusion process whereby a heated aluminum billet is forced through a die to create the desired cross-sectional shape. The extruded piece is then cut to the desired length and machined as required.3. Manufacturing DifferencesOne of the primary differences between skived and extruded heat sinks is the manufacturing process. Skived heat sinks are made using a cutting and folding process, while extruded heat sinks are made using a shaping process. The cutting and folding process used in manufacturing skived heat sinks is more precise, which can result in higher performance. However, it's also more expensive and time-consuming than the extrusion process used for manufacturing extruded heat sinks.4. Performance DifferencesSkived heat sinks have a higher surface area to volume ratio than extruded heat sinks, which means they can dissipate heat faster and more efficiently. However, this doesn't necessarily mean that skived heat sinks are always better than extruded heat sinks. The performance of a heat sink depends on a range of factors, including the application's requirements, size, shape, and the materials used.5. Design DifferencesAnother difference between skived and extruded heat sinks is the design possibilities. Skived heat sinks can be made in more complex shapes than extruded heat sinks because of the cutting and folding process used in their manufacture. This means that they can be more effective in dissipating heat from complex components and surfaces. Extruded heat sinks are typically simpler in design, but they can be produced in larger quantities and are more customizable in terms of length and width.6. Cost DifferencesAs mentioned earlier, skived heat sinks are more expensive to manufacture than extruded heat sinks. This is because the manufacturing process for skived heat sinks is more precise and requires more labor-intensive work. Skived heat sinks also require more machining and finishing work than extruded heat sinks, which adds to the Total Cost of Ownership.7. Application DifferencesThe type of heat sink that is best suited for an application depends on the application's specific requirements, including the size, shape, and heat dissipation needs. Skived heat sinks are often used in applications where higher cooling performance is required, such as LED lighting and audio amplifiers. Extruded heat sinks, on the other hand, are often used in applications that require a large heat dissipation area, such as computer power supplies and industrial equipment.8. Material DifferencesBoth skived and extruded heat sinks are commonly made from aluminum due to its high thermal conductivity and lightweight, making it an excellent heat dissipater. Other materials may also be used depending on the application's requirements, such as copper and graphite. Copper has a higher thermal conductivity than aluminum and is often used in applications where the heat source is very concentrated. Graphite is a good thermal conductor but is also brittle and less durable than aluminum and copper.9. Maintenance and Durability DifferencesSkived heat sinks are more prone to damage and require more frequent maintenance than extruded heat sinks. This is because the cutting and folding process used in the manufacture of skived heat sinks can create stress points that can break or fracture over time. Extruded heat sinks, on the other hand, have a more uniform structure and are less prone to damage over time.10. Selection DifferencesWhen selecting between skived and extruded heat sinks, it's important to consider the application's specific requirements and the desired performance levels. Skived heat sinks offer high-performance cooling but are more expensive to manufacture and maintain. Extruded heat sinks are more affordable and customizable in terms of size and shape, making them ideal for applications that require large heat dissipation areas.skived heat sinks, extruded heat sinks, heat dissipation, heat sink design, manufacturing process, material differences, maintenance, application differences, copper heat sinks, graphite heat sinksSkived vs Extruded Heat Sinks: What's the Difference?Discover the differences between skived and extruded heat sinks, including manufacturing techniques, performance, design, material, cost, and application use. Choose the right heat sink for better heat dissipation.Quote InquiryContact us!