Introduction

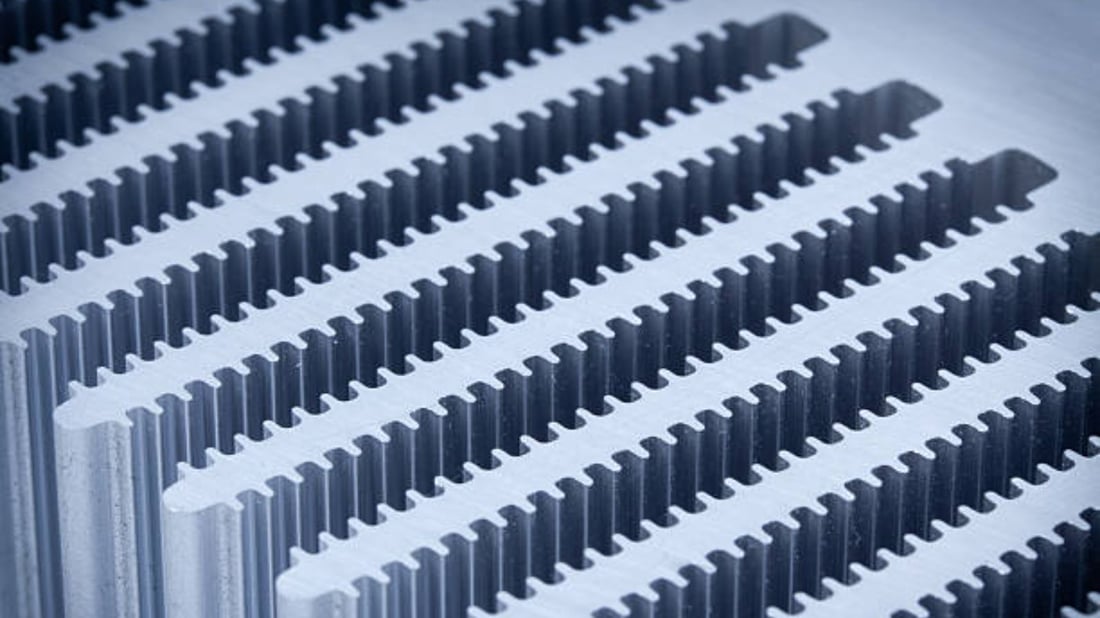

Heatsinks are an essential component in many electronic devices, including computers, gaming consoles, and servers. The purpose of a heatsink is to dissipate heat generated by these devices to prevent overheating and damage. Aluminum is a popular material used for heatsinks due to its high thermal conductivity, low cost, and lightweight nature. However, not all aluminum is created equal. In this article, we will explore what the best aluminum is for heatsinks.

6061 Aluminum

6061 aluminum is a popular choice for heatsinks. It has a thermal conductivity of 167 W/mK and is lightweight, making it a great option for high-performance applications. Its strength and durability make it an excellent choice for heatsinks that need to withstand high temperatures. This aluminum alloy also has good corrosion resistance, making it an ideal material for outdoor applications.

6063 Aluminum

6063 aluminum is another popular option for heatsinks. It has similar thermal conductivity to 6061, at 164 W/mK. This aluminum alloy is known for its excellent extrudability, meaning it can be easily shaped and formed into complex heatsink designs. 6063 also has good corrosion resistance and an attractive finish, making it a good choice for aesthetic applications.

1100 Aluminum

1100 aluminum has a lower thermal conductivity than 6061 and 6063, at 237 W/mK. However, it is an excellent choice for low-cost heatsinks that do not require high-performance capabilities. This aluminum alloy is soft and ductile, making it easy to form into various shapes and sizes. 1100 aluminum also has good corrosion resistance and is typically used for small heatsinks with low power dissipation requirements.

7075 Aluminum

7075 aluminum is a high-strength aluminum alloy that is commonly used in aerospace and military applications. It has a thermal conductivity of 130 W/mK, making it an ideal choice for heatsinks that need to withstand high temperatures. 7075 aluminum is also corrosion-resistant and has excellent fatigue strength, making it an excellent choice for high-performance heatsinks.

Other Aluminum Alloys

In addition to the above aluminum alloys, there are several others that can be used for heatsinks, including 2024, 5083, and 5754. These alloys have various properties, such as high strength or good corrosion resistance, that make them ideal for specific heatsink applications. When choosing an aluminum alloy for a heatsink, it is essential to consider the specific requirements of the application to ensure optimal performance.

Conclusion

Choosing the best aluminum for heatsinks depends on the specific requirements of the application. 6061 and 6063 are popular options for high-performance heatsinks due to their excellent thermal conductivity and extrudability. 1100 is a great choice for low-cost heatsinks with low power dissipation requirements, while 7075 is ideal for high-strength and high-temperature applications. Other aluminum alloys, such as 2024, 5083, and 5754, may also be used depending on the needs of the application. By considering the specific requirements of the application, you can choose the best aluminum for your heatsink needs.