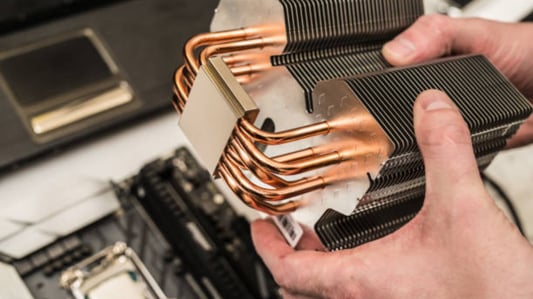

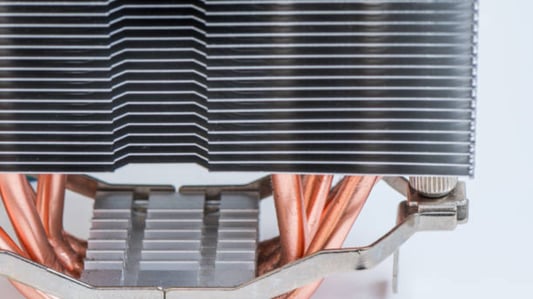

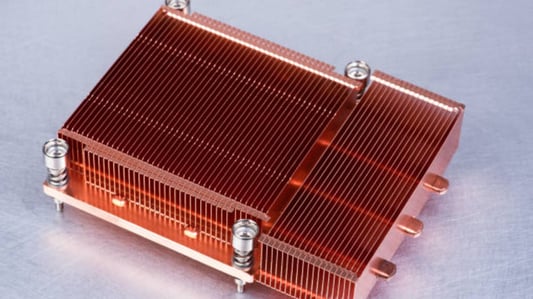

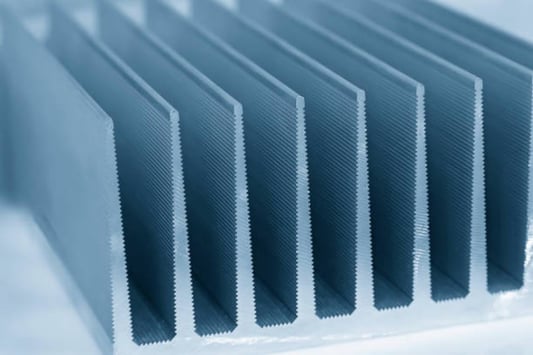

Is it okay to use SSD without a heatsink??SSDs or solid-state drives are becoming more and more popular due to their higher read and write speeds as compared to the traditional hard disk drives. Since they are primarily made of materials that don't overheat, many wonder whether it is okay to use SSDs without a heatsink. Here's everything you need to know about this topic.What is a Heatsink?A heatsink is an essential component used to absorb and dissipate heat generated by computer hardware. The primary purpose of a heatsink is to prevent the hardware from overheating and causing permanent damage.Do SSDs Need a Heatsink?Unlike CPUs and GPUs, SSDs generate minimal heat and often don't require a heatsink. Most SSDs are designed to operate within a specific temperature range, and if the temperature does not exceed the specified limit, using a heatsink is unnecessary. However, it is always best to check the manufacturer's specification before assuming that your SSD does not require a heatsink.Can You Use a Heatsink with an SSD?While most SSDs don't require a heatsink, using one won't cause any harm. In fact, adding a heatsink to your SSD may help to improve the longevity and performance of your drive. A heatsink can help to dissipate heat, which can have a positive impact on the lifespan of your SSD.What are the Benefits of Using a Heatsink with an SSD?Adding a heatsink to your SSD can have several advantages. First, it can help to keep your SSD cool, which can prevent overheating and system crashes. Second, it can help to dissipate heat, which could potentially improve the longevity and performance of your SSD. Third, a heatsink can add an aesthetic touch to your computer, making it look sleek and modern.What are the Best Heatsinks for SSDs?There are many heatsinks available for purchase online, and choosing the best one for your SSD can be overwhelming. The best heatsinks for SSDs are those that are compact and made of materials that can conduct heat effectively. Additionally, it is important to consider compatibility with your SSD before making a purchase.What are the Risks of Using a Heatsink with an SSD?While using a heatsink with an SSD typically does not pose any risks, there are a few things to consider. First, if you use a large heatsink, it may not fit in your computer case, especially if you have a smaller form factor. Second, using a heatsink may void your SSD's warranty. Before installing a heatsink, it's important to check your manufacturer's warranty policy.Do NVMe SSDs Need a Heatsink?NVMe drives are known for their high data transfer rates and are often used in high-performance systems. While most NVMe SSDs generate more heat than standard SSDs, they typically don't require a heatsink. That said, it's always best to check the manufacturer's specification before assuming that your NVMe SSD does not require a heatsink.How Do You Install a Heatsink on an SSD?The installation process of adding a heatsink to your SSD varies depending on the manufacturer and the type of heatsink. Some heatsinks require that you remove the existing adhesive on your SSD and replace it with thermal pads, while others come with pre-applied adhesive. Always read the manufacturer's instructions before attempting to install a heatsink.ConclusionIn conclusion, most SSDs do not require a heatsink, but adding one can have many benefits. Heatsinks can help to keep your SSD cool, dissipate heat, and add a sleek aesthetic touch to your computer. However, there are a few things to consider before installing a heatsink, including compatibility with your SSD and the size of your computer case. Always read the manufacturer's specifications and warranty policy before making any modifications to your computer.Quote InquiryContact us!