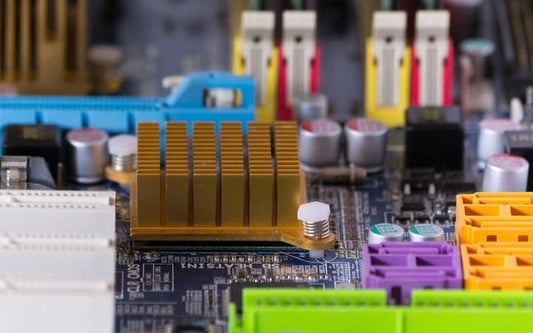

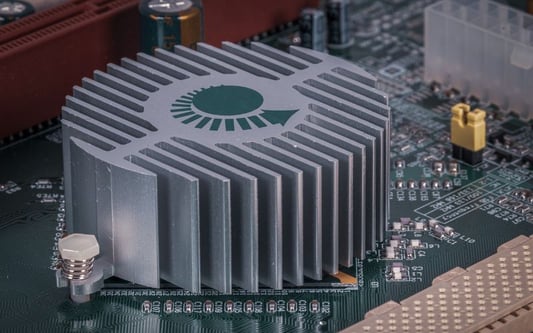

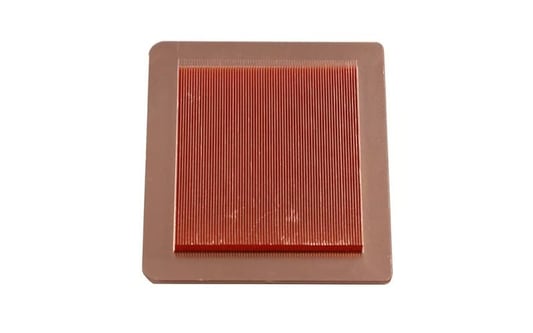

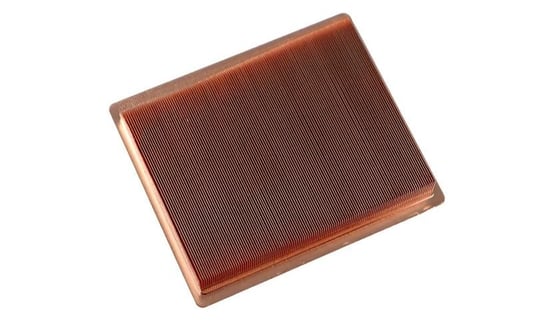

Enhanced Heat DissipationHeat sinks are designed with fins to increase the surface area available for heat dissipation. The more surface area a heat sink has, the more efficiently it can transfer heat away from the hot component.Improved Air FlowThe fins on a heat sink help to improve air flow around the component, which in turn aids in the cooling process. As air flows over the fins, heat is transferred from the heat sink to the surrounding air, keeping the component at a safe operating temperature.Increased Cooling EfficiencyThe presence of fins on a heat sink allows for more efficient cooling of electronic components. By maximizing surface area and promoting airflow, heat sinks with fins are able to dissipate heat more effectively than those without fins.Effective Thermal ManagementFins on a heat sink play a crucial role in thermal management by providing a pathway for heat to escape from the component. Without fins, heat sinks would not be as effective in preventing overheating of electronic devices.Optimal PerformanceHeat sinks with fins ensure that electronic components operate at their optimal performance levels by keeping them cool. By dissipating heat efficiently, fins help to prevent thermal throttling and ensure consistent performance.Prevention of Thermal DamageFins on a heat sink help to prevent thermal damage to electronic components by keeping them within safe operating temperatures. Without fins, heat sinks would be less effective in protecting components from overheating.Space OptimizationThe design of fins on a heat sink allows for efficient use of space within electronic devices. By maximizing surface area in a compact form factor, heat sinks with fins can effectively dissipate heat without taking up excessive space.Compatibility with Fan CoolingFins on a heat sink are compatible with fan cooling systems, as they work together to enhance heat dissipation. The fan helps to increase airflow over the fins, further improving the cooling efficiency of the heat sink.Cost-Effective Cooling SolutionHeat sinks with fins provide a cost-effective cooling solution for electronic devices, as they are relatively simple in design yet highly efficient at dissipating heat. This makes fins a popular choice for thermal management in a variety of applications.Wide Range of ApplicationsThe use of heat sinks with fins is widespread across various industries and electronic devices, including computers, smartphones, and automotive systems. Fins on heat sinks are versatile and adaptable to different cooling requirements.Quote InquiryContact us!