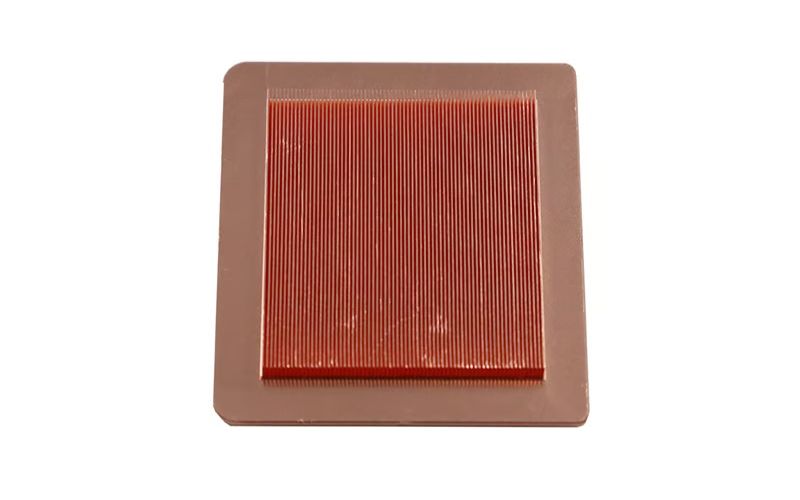

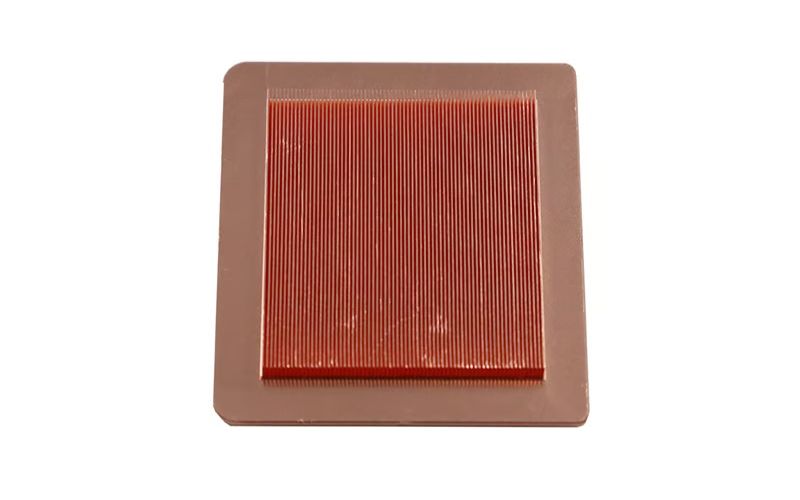

Choosing the Right Heat Sink Design

When aiming to improve heat sink efficiency, selecting the appropriate heat sink design is crucial. The design should take into consideration the specific requirements of the electronic components it will be cooling. Factors such as fin density, material conductivity, and size play a significant role in determining the effectiveness of a heat sink.

Proper Installation and Mounting

Ensuring proper installation and mounting of the heat sink is essential for optimal performance. The heat sink should be securely attached to the electronic component with thermal grease to facilitate efficient heat transfer. Any gaps or air pockets between the heat sink and the component should be minimized to enhance thermal conductivity.

Enhancing Airflow Around the Heat Sink

Improving airflow around the heat sink is another effective way to enhance its efficiency. Placing the heat sink in an area with good ventilation or incorporating additional fans or blowers can help dissipate heat more effectively. Removing any obstructions or dust build-up around the heat sink can also improve airflow.

Using Thermal Interface Materials

Utilizing high-quality thermal interface materials can significantly enhance heat sink efficiency. Thermal interface materials such as thermal pads or compounds help fill gaps and irregularities between the heat sink and the electronic component, improving thermal conductivity and heat transfer.

Optimizing Heat Sink Surface Area

Increasing the surface area of the heat sink can improve its heat dissipation capabilities. Choosing a heat sink with larger fins or adding heat sink extensions can maximize the contact area with the surrounding air, allowing for more efficient heat transfer.

Maintaining Proper Airflow Direction

Ensuring that the airflow direction around the heat sink is optimized is essential for efficient cooling. Directing airflow towards the heat sink fins and ensuring that hot air is effectively expelled can help enhance heat dissipation and overall efficiency.

Minimizing Thermal Resistance

Reducing thermal resistance within the heat sink and thermal interface is critical for improving efficiency. Using materials with high thermal conductivity, such as copper or aluminum, can help minimize resistance and facilitate better heat transfer, ultimately enhancing the heat sink's performance.

Monitoring and Managing Heat Levels

Regularly monitoring and managing heat levels within the electronic device can help identify any potential issues with the heat sink's efficiency. Implementing temperature sensors and thermal management systems can provide valuable insight into the cooling performance and help optimize heat sink efficiency.

Implementing Heat Pipes or Vapor Chambers

Incorporating heat pipes or vapor chambers into the heat sink design can significantly improve heat transfer and cooling efficiency. These components are highly effective at dissipating heat and can enhance the overall performance of the heat sink in managing thermal loads.

Considering Heat Sink Placement

The placement of the heat sink within the electronic device can impact its efficiency. Placing the heat sink in close proximity to the heat-generating components or in areas with good airflow can optimize its cooling capabilities. Additionally, considering factors such as orientation and spacing can further improve heat sink efficiency.

Quote Inquiry

Contact us!