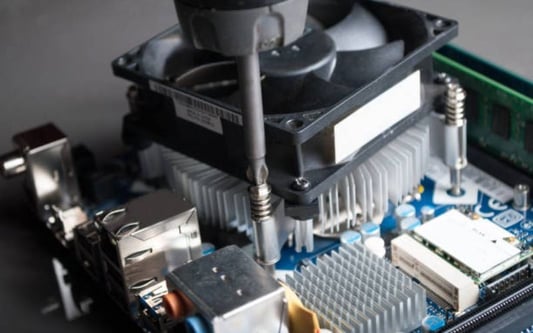

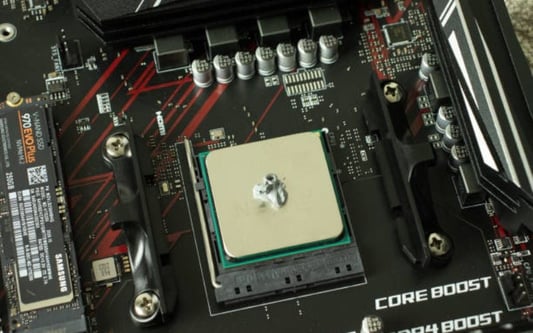

IntroductionCentral Processing Units (CPU) are devices that process data and instructions of computer programs. Their performance increases when they have better cooling systems. The two main cooling systems include air coolers and liquid coolers. However, most people confuse the terms CPU cooler and heat sink. This article will explain the differences between the two cooling systems.What is a CPU Cooler?The CPU cooler is a cooling system that consists of a heat sink, a fan, and thermal paste. Its primary function is to remove heat from the CPU. The fan on the CPU cooler helps to dissipate the heat from the heat sink. While there are various types of CPU coolers, they all have heat sinks that attach to the CPU surface to dissipate heat away from it.What is a Heat Sink?A heat sink is a passive cooling system that is primarily a metal component that dissipates heat away from the CPU. It disposes of heat through conduction, where heat moves through the metallic material to the heat sink's fins, which dissipate it into the air, and convection, where thermal energy moves in fluids. Heat sinks typically do not have fans and are best suited to managing low-power processors. However, heat sinks can get enough support from other fans on the computer chassis, such as the case fans.Size and CompatibilityCPU coolers come in various sizes and shapes and can take up a lot of space inside the computer chassis. For instance, liquid coolers usually produce more heat and take up more space than air coolers. On the other hand, heat sinks much smaller in size. It is best to make sure that the cooler is compatible with the computer's CPU socket to avoid any complications, such as damage to the CPU over time. Checking the size of the cooler and the chassis to ensure compatibility is critical when choosing between the two.Performance and NoiseCPU coolers help to enhance the performance of the computer. Better cooling systems can ensure that the device runs smoothly without any overheating problems. However, some coolers can be quite noisy, and the sound may not be suitable for the user if they want a quieter experience. On the other hand, heat sinks generate little or no noise, as they use less energy to function and do not have fans that are responsible for the noise.Accessibility and MaintenanceCPU coolers are accessible and easy to install compared to heat sinks. They typically come with a thermal paste and mounting kit that makes it easy to attach the cooler to the CPU. Heat sinks, on the other hand, are more challenging to install and require more knowledge of your computer's system. Both heat sinks and coolers need maintenance, and they should be regularly cleaned to ensure optimal performance.PriceCPU coolers tend to be more expensive than heat sinks. However, this is not always the case, as some high-end heat sinks can be more expensive than CPU coolers. It is best to look at the price of the cooler and its capabilities before making a purchase decision.Customization and AestheticsCPU coolers offer more customization options, such as RGB lighting, customization of fan speed and performance, and the option to add more fans. This enhances the user's experience and offers more customization to their device. On the other hand, heat sinks have a simpler design and do not have much customization option; they are more focused on doing their primary function of dissipating heat.Power Consumption and CompatibilityCPU coolers require power to operate, and they can be quite power-hungry. However, they are compatible with a wide range of hardware components, including high-end processors. Heat sinks have lower power consumption rates than CPU coolers, which makes them the best choice for laptops or other mobile devices.Space and Design IntegrationCPU coolers usually have more space dedicated to accommodating the cooling systems and are designed with this in mind. Heat sinks, on the other hand, are smaller and require less space in the computer chassis. This makes them a good option for small form-factor PCs or other devices with limited space.ConclusionTo summarize, CPU coolers and heat sinks have different designs and functions. CPU coolers offer better performance, customization options, and accessibility, while heat sinks are smaller, generate less noise, and have lower power consumption rates. When making a purchase decision, it is best to consider the price, compatibility, size, and compatibility of your hardware components.Quote InquiryContact us!