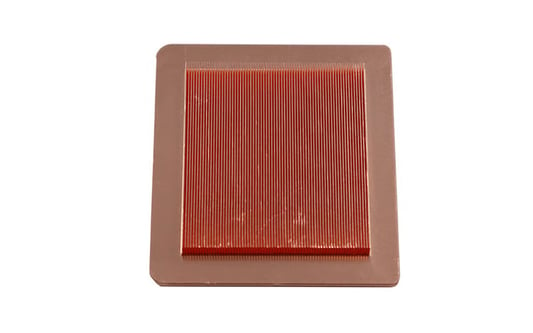

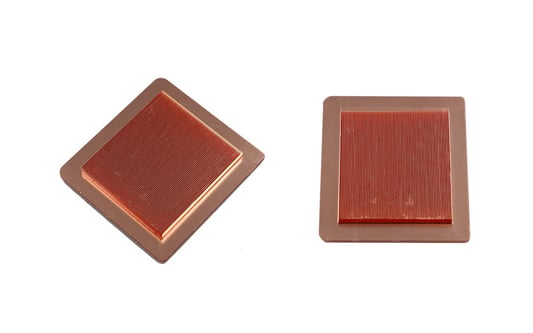

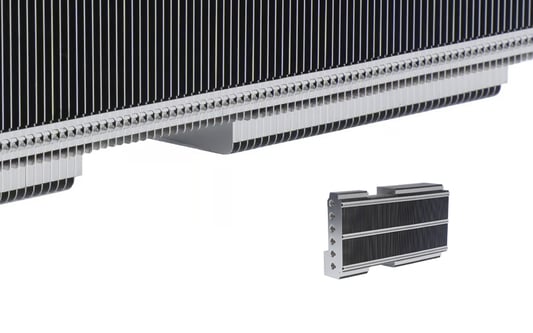

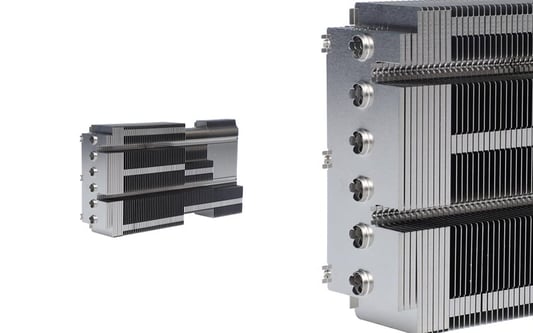

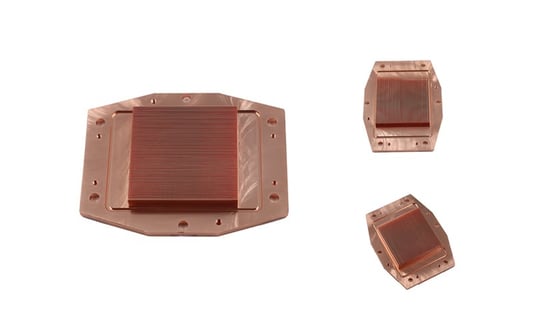

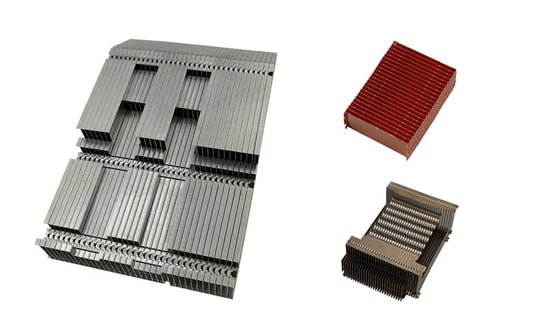

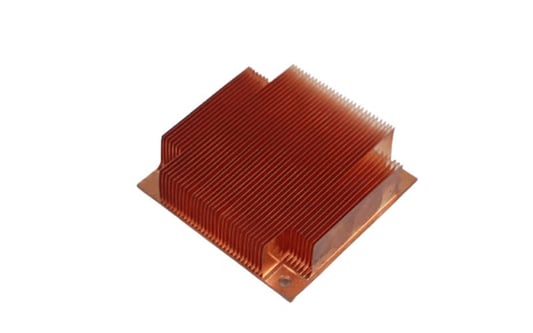

Improved Heat DissipationSkived heat sinks are widely used in modern electronics for their ability to efficiently dissipate heat from electronic components, preventing overheating and potential damage. This method of thermal management involves the creation of thin fins on a metal base, which increases the surface area for heat transfer.Compact DesignOne of the key advantages of skived heat sinks is their compact design, making them ideal for applications where space is limited. The thin fins allow for effective heat dissipation without adding bulk to electronic devices, ensuring optimal performance in a compact form factor.Enhanced Thermal PerformanceSkived heat sinks offer enhanced thermal performance compared to traditional heat sink designs. The efficient heat dissipation capabilities of skived heat sinks translate to better overall thermal management in modern electronics, improving the reliability and longevity of electronic components.Customization OptionsManufacturers can easily customize skived heat sinks to meet the specific thermal requirements of different electronic devices. This level of customization allows for the creation of heat sinks tailored to the unique needs of a particular application, ensuring optimal thermal performance and reliability.Cost-Effective SolutionSkived heat sinks offer a cost-effective solution for thermal management in modern electronics. Their efficient heat dissipation capabilities reduce the need for additional cooling measures, saving on energy costs and extending the lifespan of electronic components.Compatibility with Various MaterialsSkived heat sinks are compatible with a wide range of materials, making them versatile for use in different electronic applications. From aluminum to copper, skived heat sinks can be manufactured using various materials to optimize heat transfer and thermal performance.Application in LED LightingSkived heat sinks are commonly used in LED lighting fixtures to dissipate heat generated by the light-emitting diodes. The compact design and efficient heat dissipation capabilities of skived heat sinks make them an ideal thermal management solution for high-intensity LED applications.Utilization in Power ElectronicsSkived heat sinks play a crucial role in power electronics, where efficient thermal management is essential for maintaining optimal performance. These heat sinks help to dissipate excess heat generated by power electronic components, ensuring reliable operation and preventing thermal issues.Integration in Automotive ElectronicsIn automotive electronics, skived heat sinks are integrated into various systems to regulate the temperature of electronic components, especially in high-temperature environments. The compact and customizable nature of skived heat sinks makes them well-suited for automotive applications.Advancements in Processor CoolingSkived heat sinks are increasingly being used in processor cooling solutions for their ability to efficiently dissipate heat generated by high-performance CPUs. By incorporating skived heat sinks into processor cooling systems, manufacturers can improve thermal performance and optimize the efficiency of electronic devices.Quote Inquirycontact us