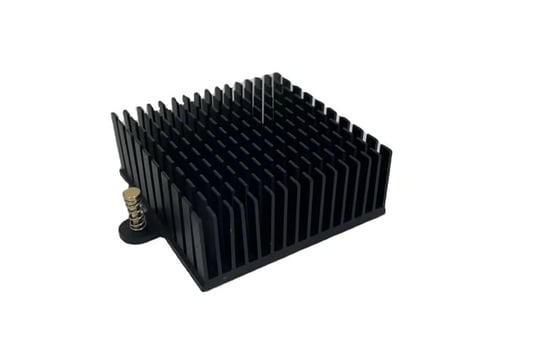

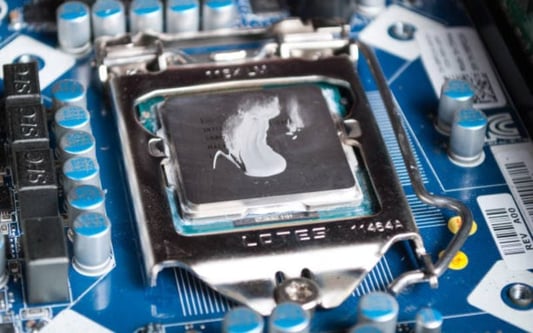

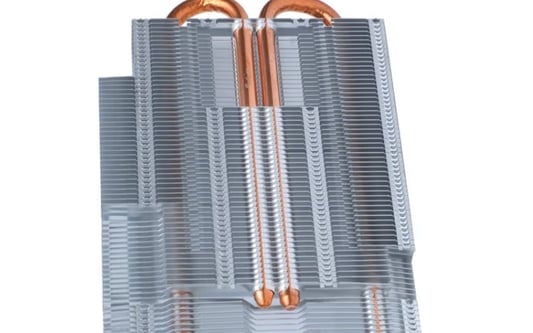

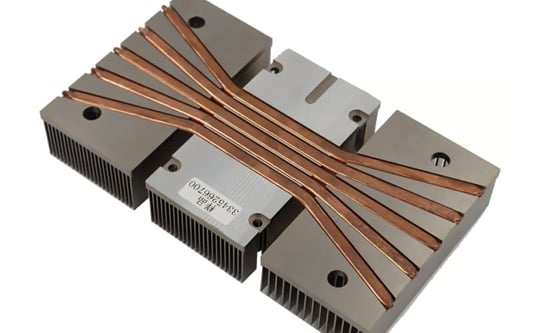

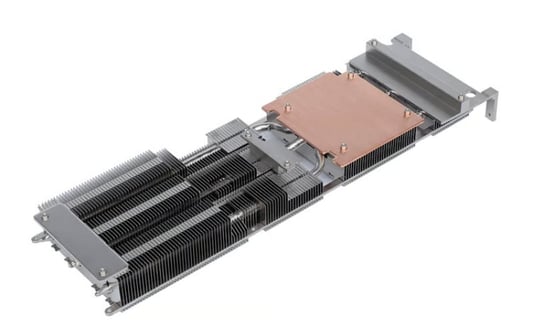

IntroductionOne of the most important components of a computer is the central processing unit (CPU), which requires proper cooling to perform optimally. Two common types of CPU coolers are vapor chamber and heat pipe coolers. This article aims to compare and contrast these two types and determine which is better for your computer.What is a Vapor Chamber CPU Cooler?A vapor chamber CPU cooler is a type of cooler that uses a flattened copper structure with a small amount of water inside. The water vaporizes and spreads over the chamber, resulting in efficient heat transfer. This type of cooler is usually more expensive but also offers better cooling performance than heat pipe coolers.What is a Heat Pipe CPU Cooler?A heat pipe CPU cooler, on the other hand, uses several copper pipes that are filled with a liquid that evaporates when heated. The vapor travels through the pipes and condenses back into a liquid, releasing heat in the process. Heat pipe coolers are more affordable than vapor chamber coolers but offer lower cooling performance.Cooling PerformanceWhen it comes to cooling performance, vapor chamber coolers are generally better than heat pipe coolers. The larger surface area of the vapor chamber allows for more efficient heat transfer, resulting in lower CPU temperatures. However, heat pipe coolers are still suitable for most computers and offer sufficient cooling performance.Noise LevelVapor chamber coolers are quieter than most heat pipe coolers, mainly due to their larger surface area. The larger the surface area, the less the fans have to work to cool the CPU, resulting in lower noise levels. However, some high-end heat pipe coolers come with efficient fans that keep them quiet.Compatibility with Different CPUsBoth types of cooler are compatible with different CPUs and motherboard sockets. When choosing a cooler, make sure to check the manufacturer's compatibility list to ensure that it will fit your CPU and motherboard.PriceWhen it comes to price, heat pipe coolers are generally more affordable than vapor chamber coolers. Vapor chamber coolers are usually designed for high-end computers and come with a premium price. However, both types of cooler can provide sufficient cooling performance for most computer users.Installation DifficultyBoth types of cooler require a certain level of technical expertise to install. However, heat pipe coolers are generally easier to install than vapor chamber coolers due to their simpler design.MaintenanceBoth types of cooler require some maintenance to ensure efficient cooling performance. This usually involves cleaning the fans and heatsinks regularly to remove dust buildup. Heat pipe coolers are generally easier to maintain due to their simpler design.ConclusionBoth vapor chamber and heat pipe CPU coolers have their advantages and disadvantages. Vapor chamber coolers offer better cooling performance and are quieter but are also more expensive. Heat pipe coolers, on the other hand, are more affordable and easier to install and maintain.cpu cooler, vapor chamber, heat pipe, cooling performance, noise level, compatibility, price, installation, maintenanceWhich is Better: Vapor Chamber or Heat Pipe CPU Cooler?Discover which CPU cooler is better for your computer performance: Vapor Chamber or Heat Pipe. Read this article to compare and contrast both types.Quote InquiryContact us!