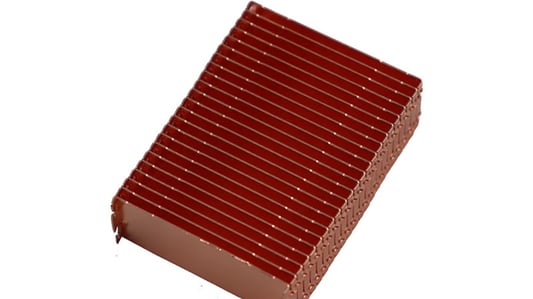

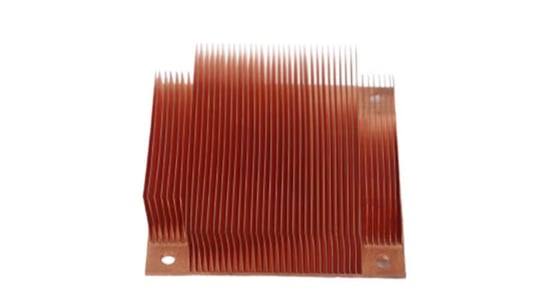

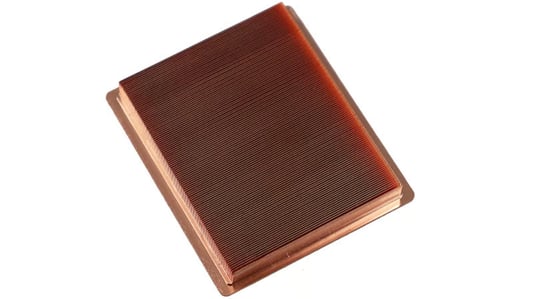

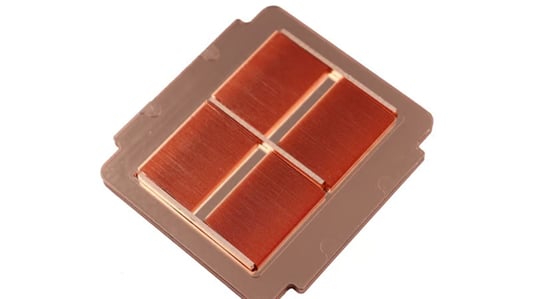

Aluminum Heatsink FinsWhen it comes to heatsink fins, aluminum is one of the most common materials used due to its high thermal conductivity and lightweight properties. Aluminum fins are often designed with a series of ridges or pins that help to increase surface area for improved heat dissipation.Copper Heatsink FinsCopper heatsink fins are known for their excellent thermal conductivity, making them ideal for applications that require efficient heat transfer. Copper fins can be found in high-performance heatsinks where optimal cooling is essential.Skived Heatsink FinsSkived heatsink fins are manufactured by cutting thin sheets of metal into a specific shape to create a series of fins. This process allows for precise customization of the fins' thickness and height, resulting in enhanced thermal performance.Extruded Heatsink FinsExtruded heatsink fins are created by pushing heated aluminum or copper through a die to form the desired shape. This manufacturing process produces fins with consistent thickness and height, making them suitable for a wide range of heatsink applications.Pin Heatsink FinsPin heatsink fins, also known as straight fins, are cylindrical in shape and are stacked closely together to maximize surface area. These fins are commonly used in compact heatsink designs where space is limited but efficient cooling is still required.Serrated Heatsink FinsSerrated heatsink fins feature a zigzag pattern along the edges of each fin, which helps to disrupt airflow and improve heat dissipation. This design is effective at reducing air resistance and enhancing overall cooling performance.Blank Heatsink FinsBlank heatsink fins are simple, flat sheets of metal that are typically used in low-power applications where minimal heat dissipation is needed. These fins are cost-effective and easy to manufacture, making them a popular choice for basic cooling requirements.High-Density Heatsink FinsHigh-density heatsink fins are characterized by their closely spaced fins, which provide a large surface area in a compact form factor. These fins are ideal for high-power applications where maximum heat dissipation is crucial.Variable Height Heatsink FinsVariable height heatsink fins are designed with fins of varying heights to optimize airflow and heat transfer. By strategically adjusting the height of the fins, these heatsinks can achieve more uniform cooling across the entire surface area.Custom Heatsink FinsCustom heatsink fins are tailored to specific thermal requirements and space constraints of a particular application. These fins can be designed in various shapes, sizes, and configurations to achieve optimal cooling performance in unique environments.Quote InquiryContact us!