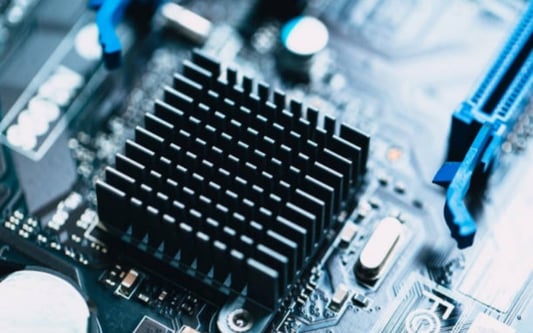

Should the heat sink touch the CPU? Exploring the Pros and ConsWhen it comes to building or maintaining a computer, there are numerous factors to consider to ensure optimal performance and longevity. One important aspect is the relationship between the heat sink and the CPU. In this article, we will delve into the question: Should the heat sink touch the CPU? Let's explore the pros and cons of this critical component in computer cooling.The Purpose of a Heat SinkBefore we dive into the main question, let's first understand the purpose of a heat sink. A heat sink is a passive cooling device that helps dissipate heat generated by the CPU. It typically consists of metal fins or plates that provide a larger surface area for heat to escape into the surrounding air. The heat sink works in conjunction with a fan or other cooling mechanisms to maintain a safe operating temperature for the CPU.The Importance of Proper ContactOne of the key factors in heat transfer efficiency is the contact between the heat sink and the CPU. Proper contact ensures maximum heat dissipation and prevents overheating, which can lead to performance issues or even permanent damage to the CPU. So, should the heat sink touch the CPU? The answer is yes, but with some important considerations.The Benefits of Direct ContactWhen the heat sink is in direct contact with the CPU, heat transfer occurs more efficiently. The direct contact allows for better conduction of heat from the CPU to the heat sink, which in turn facilitates effective cooling. This ensures that the CPU operates within its recommended temperature range, promoting optimal performance and stability.Potential Risks of Direct ContactWhile direct contact between the heat sink and the CPU offers benefits, there are also potential risks to be aware of. One concern is the possibility of damaging the CPU during installation. If excessive force is applied while attaching the heat sink, it can result in bent pins or other physical damage to the delicate CPU. Therefore, caution and proper technique are crucial when installing the heat sink.Thermal Paste: A Critical ElementThermal paste plays a vital role in ensuring proper heat transfer between the CPU and the heat sink. It fills in microscopic gaps and imperfections on the CPU and heat sink surfaces, improving contact and reducing thermal resistance. Applying an appropriate amount of thermal paste is essential to achieve optimal heat transfer and prevent overheating.Considerations for AirflowEfficient airflow is essential for effective heat dissipation. When installing the heat sink, it is crucial to consider the overall airflow within the computer case. The heat sink should be oriented in a way that aligns with the airflow direction, allowing hot air to be expelled efficiently. Additionally, ensuring proper cable management and keeping the computer case clean from dust and debris can help maintain optimal airflow.Heat Sink Mounting MechanismsThere are different mounting mechanisms for heat sinks, including push-pin, clip, screw, and adhesive methods. The choice of mounting mechanism depends on the specific CPU and heat sink model. It is important to follow the manufacturer's instructions and use the appropriate mounting mechanism to ensure a secure and proper fit. This helps maintain consistent contact between the heat sink and the CPU.The Role of Heat PipesHeat pipes are often integrated into high-performance heat sinks to enhance heat transfer. These pipes contain a liquid or gas that evaporates when heated, carrying the heat away from the CPU and towards the heat sink's fins. Heat pipes can significantly improve the cooling efficiency of the heat sink and are commonly used in gaming PCs and other systems that require intensive processing power.Consider Professional InstallationIf you are unsure about installing the heat sink yourself or want to ensure the best possible results, it may be wise to seek professional assistance. A computer technician or specialist can provide expert guidance and ensure that the heat sink is properly installed and in optimal contact with the CPU. This can help avoid any potential issues or risks associated with improper installation.ConclusionIn conclusion, the heat sink should indeed touch the CPU to ensure efficient heat transfer and prevent overheating. However, proper installation, the use of thermal paste, and considerations for airflow are crucial to maximize cooling performance. By following the manufacturer's instructions and taking necessary precautions, you can ensure that your computer operates at its best and remains cool under demanding tasks.Quote InquiryContact us!