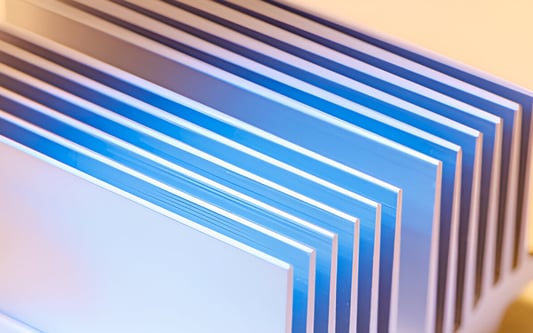

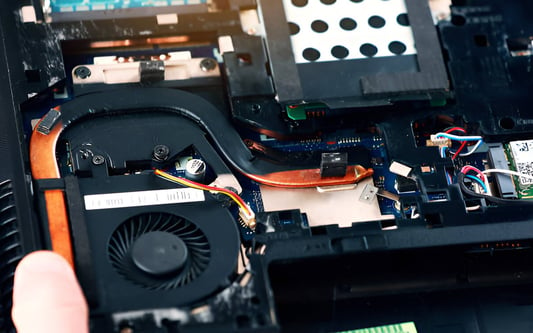

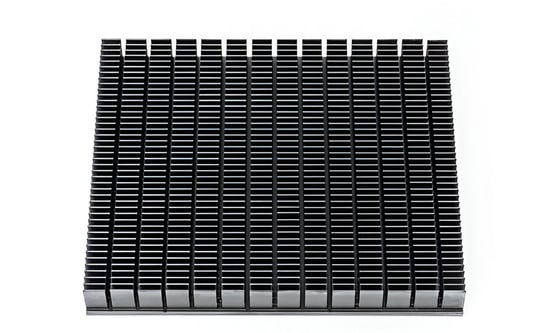

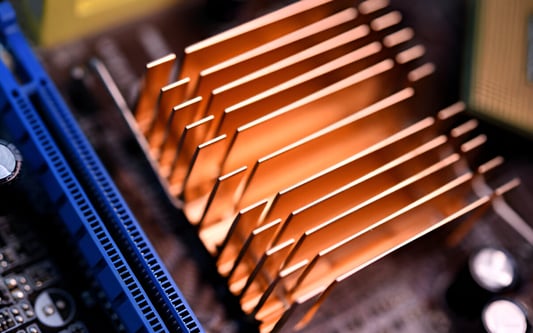

Introduction RAM or Random Access Memory is essential in modern computing systems. It allows your computer to access information quickly and efficiently, making it an essential component in any computer system. However, when it comes to RAM, you have different types available in the market. One of them is a heat sink RAM, and it comes with a lot of benefits that make it stand out. In this article, we will discuss the benefits of heat sink RAM and understand why it is an excellent choice for your computer. Better Performance Heat sink RAM helps to dissipate the heat generated when the RAM is working. When the temperature of the RAM increases, its performance also decreases. Therefore, when you are using heat sink RAM, you can be sure that the RAM will work optimally and will not suffer from thermal throttling. As a result, you get better performance from your computer. Longer Lifespan When you use heat sink RAM, you can be sure that your computer's RAM will last longer. Due to the heat sink's presence, the RAM is protected from excessive heat, which can damage the chips over time. Therefore, if you want your computer to last longer, you should consider using heat sink RAM. Improved Overclocking Potential Overclocking is a process of increasing your computer's performance by pushing the components of your computer to work at a higher frequency than usual. This process generates more heat, and if your RAM is not adequately cooled, it can heat up and reduce its performance, but with heat sink RAM, overclocking your RAM becomes easier by keeping it cool. Better Stability Heat sink RAM helps to stabilize your computer system. When your RAM is being used to its maximum capacity, it can lead to the RAM overheating, which can cause your system to crash. By using heat sink RAM, you can stabilize your computer system and ensure that it can handle the demands placed on it. Less Noise Heat sink RAM reduces the noise your computer generates. RAM generates heat, which can cause it to produce noise. When you use heat sink RAM, it dissipates the heat, and as a result, the noise level of your computer is significantly reduced. Efficient Power Usage Heat sink RAM is more efficient in using power. The presence of the heat sink helps reduce the power required to operate the RAM. This can lead to a reduction in electricity bills, making it an attractive option for businesses where cost-cutting is a priority. Cooling System Compatibility Heat sink RAM is compatible with cooling systems that use air or water to cool the system. When you are using a high-end cooling system, the heat sink RAM can be an excellent addition and achieve the best results. Improved Aesthetics Heat sink RAM is designed to look attractive. It adds a professional look to the overall system and improves its aesthetics, making it an excellent addition to gaming setups or any aesthetically minded computer system. Competitive Advantage in Gaming and High-Performance Tasks Heat sink RAM is an excellent choice for gaming and high-performance tasks. Gamers need high-performance RAM that can handle the demands of the game, and heat sink RAM provides a stable and reliable option that can handle the demands. Conclusion Heat sink RAM provides several benefits that make it stand out as an excellent choice for any computer system. It offers better performance, longer lifespan, improved overclocking potential, better stability, less noise, efficient power usage, cooling system compatibility, improved aesthetics, and a competitive advantage in gaming and high-performance tasks. Therefore, if you are looking to upgrade your computer system, you should consider using heat sink RAM.Quote InquiryContact us