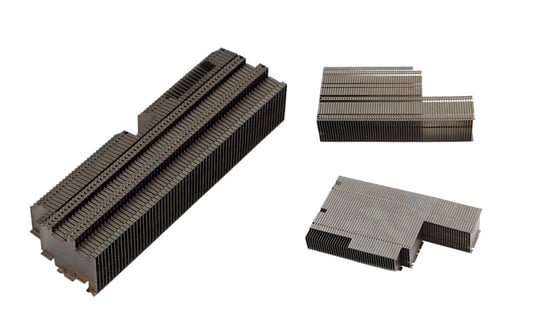

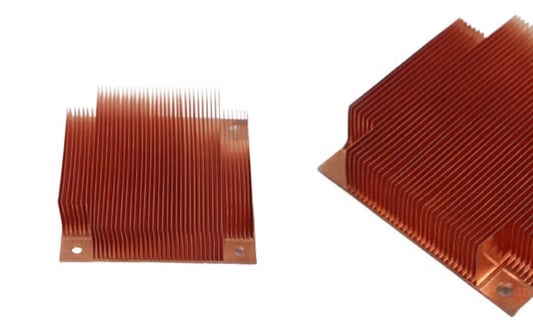

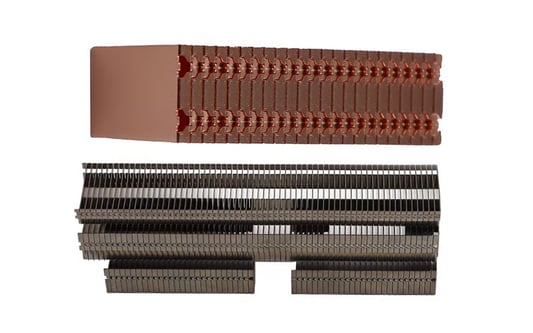

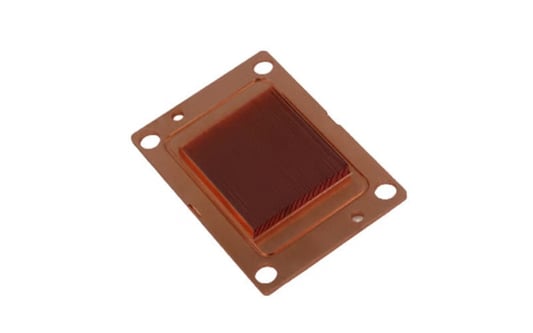

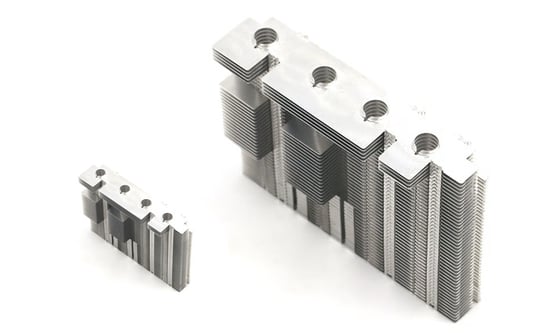

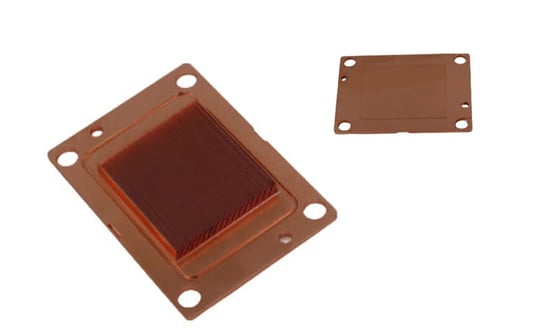

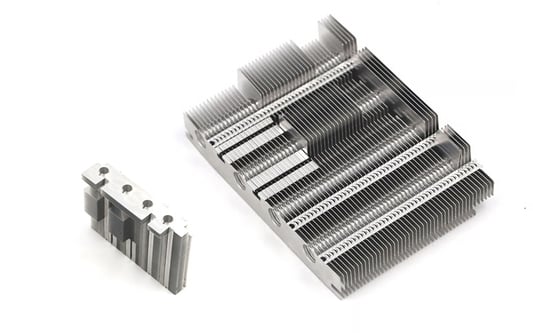

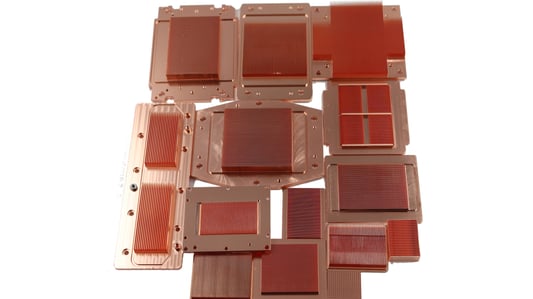

What is a telecom heat sink? A telecom heat sink is a passive component that is used to dissipate heat from electronic components in devices such as routers, servers, and telecommunications equipment. These heat sinks are essential to prevent overheating and ensure the longevity and optimal performance of electronic devices. How Does a Telecom Heat Sink Work? Telecom heat sinks work by providing a path for heat to travel away from the electronic components, allowing for the heat to be transferred to the surrounding environment. This process helps to maintain the operating temperature of the device within safe limits, preventing thermal issues that can lead to malfunctions and damage. The Importance of Proper Heat Dissipation Proper heat dissipation is crucial in electronic devices, especially in the telecommunications industry where equipment is often running 24/7. Without effective heat sinks, the components can reach dangerously high temperatures, leading to decreased performance and potential failure. Types of Heat Sinks for Telecom Applications There are various types of heat sinks available for telecom applications, including passive heat sinks, active heat sinks with fans, and liquid cooling systems. The choice of heat sink depends on factors such as the amount of heat generated, space limitations, and cost considerations. Benefits of Using Telecom Heat Sinks Using heat sinks in telecom equipment offers several benefits, including improved reliability, extended lifespan of components, reduced maintenance costs, and enhanced overall performance. Heat sinks are a cost-effective solution to prevent thermal issues and ensure the longevity of electronic devices. Design Considerations for Telecom Heat Sinks When designing telecom heat sinks, factors such as material selection, size, shape, and surface area are crucial in optimizing heat dissipation. The design must effectively transfer heat away from the components while fitting within the constraints of the device and environment. Installation and Maintenance of Heat Sinks Proper installation and maintenance of heat sinks are essential to ensure optimal performance. Regular cleaning, checking for dust buildup, and monitoring temperature levels are all important tasks to prevent overheating and maintain the efficiency of the heat sink. Latest Trends in Telecom Heat Sink Technology Advancements in heat sink technology have led to innovations such as micro-fin heat sinks, vapor chamber cooling, and phase change materials for enhanced thermal management. These developments help to meet the increasing demands for efficient heat dissipation in telecom devices. Importance of Quality Materials in Telecom Heat Sinks Using high-quality materials in the manufacturing of telecom heat sinks is crucial to ensure reliability and longevity. Materials such as aluminum, copper, and composite alloys offer excellent thermal conductivity and durability, making them ideal choices for heat sink applications. Conclusion Telecom heat sinks play a vital role in maintaining the optimal operating temperature of electronic devices in the telecommunications industry. By dissipating heat effectively, heat sinks help prevent thermal issues, improve performance, and prolong the lifespan of components. Investing in quality heat sinks and incorporating the latest advancements in heat sink technology are essential to ensure the reliability and efficiency of telecom equipment. Quote Inquirycontact us