Introduction

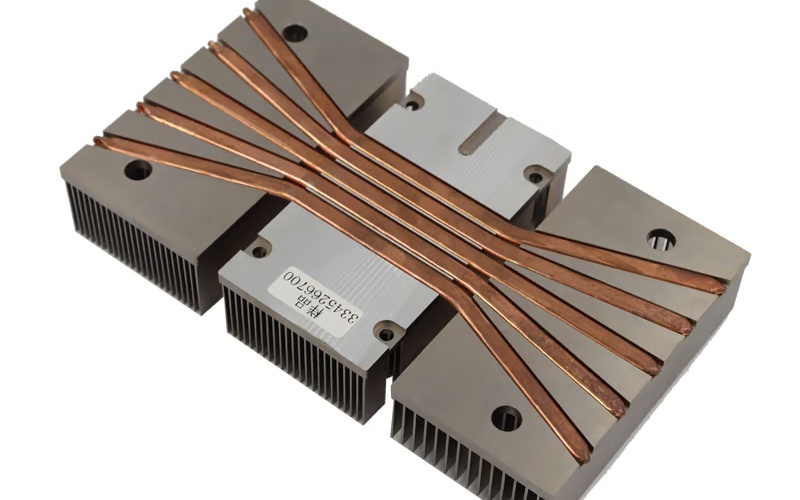

Heat sinks are devices used to disperse heat from hot components in electronic devices. They are made of various materials, but the most commonly used is metal. Choosing the right metal for a heat sink can be crucial for the overall performance of the device. In this article, we will discuss the best metal for a heat sink and the factors to consider when selecting it.

Thermal Conductivity

One of the most critical factors to consider when choosing the best metal for a heat sink is thermal conductivity - the ability of a material to conduct heat. The higher the thermal conductivity, the better it is for a heat sink. Copper, silver, aluminum, and gold are some of the metals with high thermal conductivity, making them the best choices for heat sink applications.

Cost

In most cases, cost is a significant factor when choosing the best metal for a heat sink. Copper and silver are the most expensive metals, while aluminum is relatively cheap. Gold is the most expensive metal, but it is not widely used for heat sink applications due to its cost.

Weight

Another consideration when choosing the best metal for a heat sink is weight. Copper and silver are heavy, which can be a challenge when designing an electronic device with space limitations. Aluminum has a lower weight than copper and silver, making it a better choice for compact devices.

Coefficient of Thermal Expansion (CTE)

The CTE is the rate at which a material expands or contracts as its temperature changes. When a heat sink is exposed to temperature fluctuations, the CTE can cause stress on the device, leading to failure. Metals with low CTE are the best choices for heat sink applications. Copper, silver, and gold have low CTE, making them suitable for heat sinks. Aluminum has a higher CTE than copper, but this can be managed by design adjustments in the heat sink.

Corrosion Resistance

Corrosion resistance is another critical factor to consider when choosing the best metal for a heat sink. When a heat sink is in use, it is exposed to different environmental conditions that can cause corrosion. Copper and silver are the most corrosion-resistant metals used in heat sink applications, while aluminum is more susceptible to corrosion. Gold has excellent corrosion resistance, but its high cost makes it impractical for most applications.

Mechanical Properties

The mechanical properties of a metal also play a role in selecting the best metal for a heat sink. The metal used must be durable and able to withstand the mechanical stress generated during operation. Copper is the most durable metal, with a high yield strength, making it the preferred choice for high-performance heat sinks. Silver also has good mechanical properties, although it is more expensive than copper. Aluminum has lower mechanical strength, making it less durable when compared to copper and silver.

Machinability

The ability to work with a metal easily is essential when designing and manufacturing a heat sink. Copper and aluminum are easy to machine, making them the most popular choices for heat sink applications. Silver is also easy to work with, but its cost makes it less popular than copper and aluminum.

Electrical Conductivity

Heat sinks can also affect the electrical performance of electronic devices. Metals used in heat sinks should have low electrical resistance to prevent interference with the device's electrical function. Copper, silver, and gold have excellent electrical conductivity, making them the best metals for heat sink applications. Aluminum has lower electrical conductivity than copper and silver, but it is still acceptable for most applications.

Aesthetics

The appearance of a heat sink is also essential for some electronic device manufacturers. Copper and gold have a unique appearance, but they are more expensive. Aluminum is cheaper and can be anodized, giving it a variety of color options for aesthetics purposes.

Conclusion

Choosing the best metal for a heat sink depends on various factors such as thermal conductivity, cost, weight, CTE, corrosion resistance, mechanical properties, machinability, electrical conductivity, and aesthetics. Copper is the most commonly used metal, followed by aluminum, for most heat sink applications. Silver and gold are less popular due to their high cost. Understanding these factors can help electronic designers and manufacturers select the best metal for their heat sink application and improve the overall performance of their devices.