Introduction to Liquid Cold Plates

Liquid cold plates are essential components in cooling systems to dissipate heat generated by electronic devices. Their efficiency is crucial for maintaining optimal operating temperatures and preventing overheating.

Types of Liquid Cold Plates

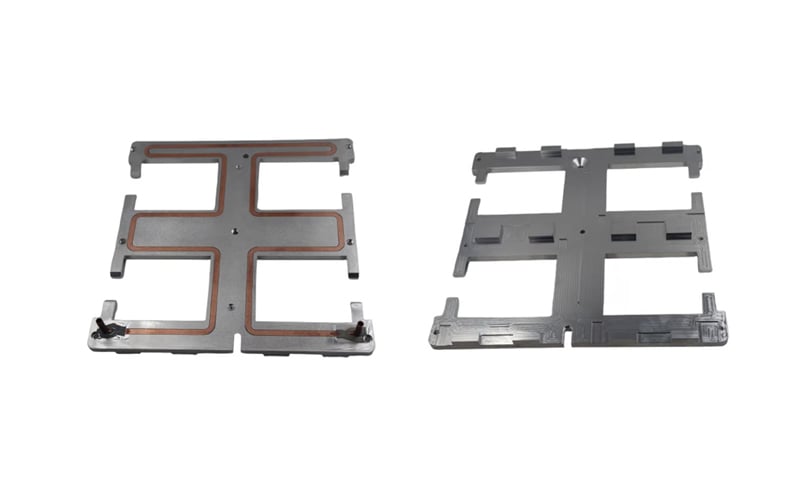

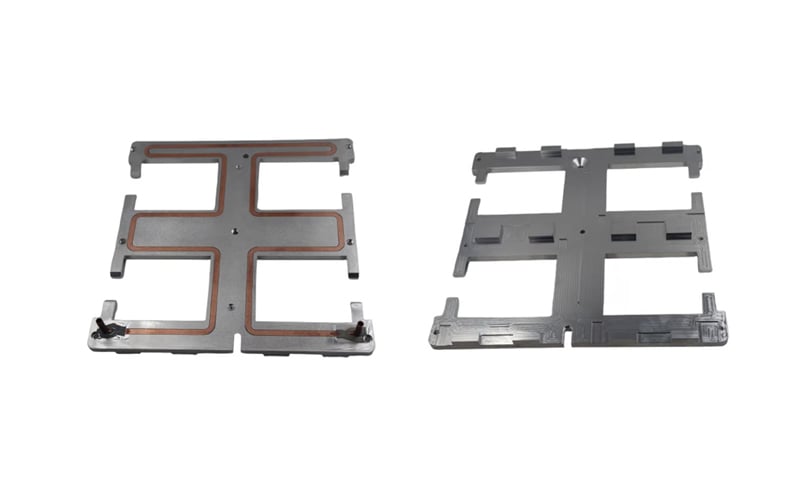

There are two primary types of liquid cold plates: tubed and brazed. Tubed cold plates consist of a network of tubes through which coolant flows, while brazed cold plates have channels etched or machined into a single piece of metal.

Materials Used in Cold Plates

Cold plates are typically made from materials with high thermal conductivity, such as copper or aluminum. These materials help transfer heat away from the electronic components to the coolant circulating through the cold plate.

Design Considerations for Efficiency

The design of a liquid cold plate plays a significant role in its efficiency. Factors such as channel geometry, flow rate, and material thickness can impact heat dissipation and overall cooling performance.

Working Principle of Cold Plates

Liquid cold plates work on the principle of conduction, where heat is transferred from the hot electronic components to the cold plate, and then dissipated into the circulating coolant. This process helps maintain the temperature of the electronic system within safe operating limits.

Integration with Cooling Systems

Liquid cold plates are often integrated into larger cooling systems, such as liquid cooling loops or refrigeration units. This seamless integration ensures efficient heat transfer and optimal cooling performance for the electronic devices.

Advantages of Liquid Cold Plates

Liquid cold plates offer several advantages over air-cooled systems, including higher thermal transfer efficiency, lower operating temperatures, and reduced noise levels. These benefits make them ideal for high-performance electronic applications.

Applications of Liquid Cold Plates

Liquid cold plates are commonly used in industries such as telecommunications, aerospace, and automotive, where electronic devices generate significant amounts of heat. They are also utilized in medical equipment and renewable energy systems.

Innovations in Cold Plate Technology

Recent advancements in cold plate technology have focused on improving thermal conductivity, reducing pressure drop, and enhancing overall performance. These innovations have led to more efficient and compact cold plate designs.

Future Trends in Liquid Cooling

As electronic devices continue to increase in power and complexity, the demand for efficient cooling solutions like liquid cold plates will rise. Future trends may include the use of advanced materials, smart cooling controls, and customizable cold plate configurations to meet specific cooling requirements.

Quote Inquiry

Contact us