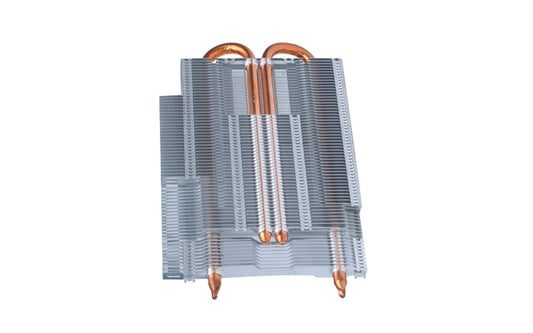

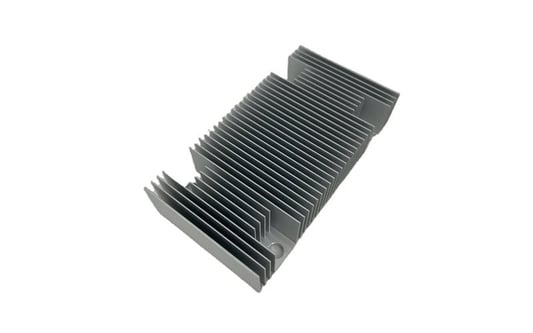

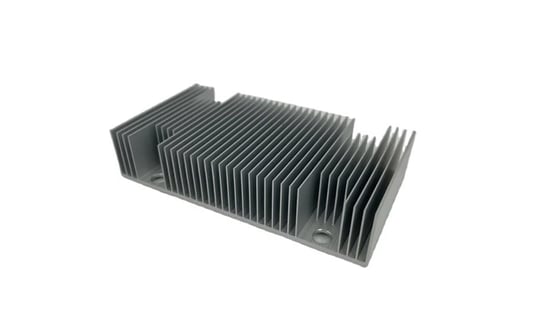

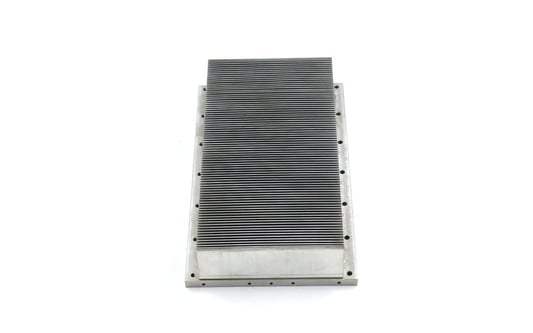

When it comes to the efficient functioning of electric vehicles (EVs), the heat sink module plays a crucial role in ensuring that the power electronics components operate at optimal temperatures.As EVs continue to gain popularity due to their environmental benefits and cost savings, the demand for reliable heat sink modules for power electronics is on the rise.It is essential to understand the significance of a high-quality Heat Sink Module for EV Power Electronics in order to maximize the performance and lifespan of these vehicles.Let's take a closer look at the various aspects of a heat sink module for EV power electronics and why it is a vital component in the design and operation of electric vehicles.Efficient Thermal ManagementThe primary function of a heat sink module for EV power electronics is to dissipate heat generated by the components during operation. Efficient thermal management is crucial to prevent overheating and ensure the longevity of the power electronics.Enhanced PerformanceBy maintaining optimal operating temperatures, a high-quality heat sink module can help improve the overall performance of the power electronics in electric vehicles. This leads to increased efficiency and reliability of the EVs.Extended LifespanProper thermal management provided by a heat sink module can significantly extend the lifespan of power electronics components in EVs. By preventing overheating and thermal stress, the longevity of the vehicle is increased.Compact DesignHeat sink modules for EV power electronics are designed to be compact and lightweight, while still providing efficient heat dissipation. This allows for integration into the limited space available in electric vehicles without compromising performance.Customizable SolutionsManufacturers of heat sink modules offer customizable solutions to meet the specific requirements of different EV power electronics systems. This ensures optimal thermal management for various components in the vehicle.Reliability and DurabilityA well-designed heat sink module enhances the reliability and durability of power electronics in electric vehicles. By effectively managing heat, the components are protected from thermal damage and premature failure.Cost-Effective SolutionInvesting in a high-quality heat sink module for EV power electronics may initially seem like an additional cost, but in the long run, it proves to be a cost-effective solution by extending the lifespan of components and reducing maintenance and repair costs.Environmental ImpactEfficient thermal management provided by a heat sink module contributes to the overall sustainability of electric vehicles. By reducing energy consumption and extending the life of components, it helps minimize the environmental impact of EVs.Technological AdvancementsOngoing technological advancements in heat sink modules continue to improve the efficiency and performance of EV power electronics. Innovations in materials and design make them more effective in managing heat and enhancing the overall operation of electric vehicles.Quote Inquirycontact usFactory