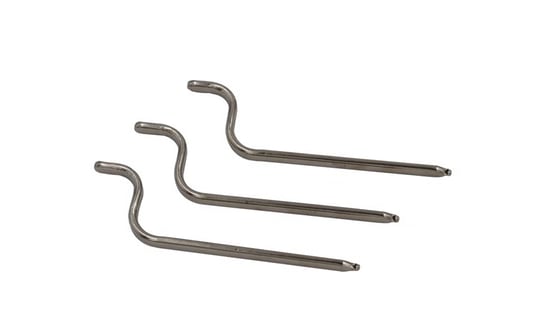

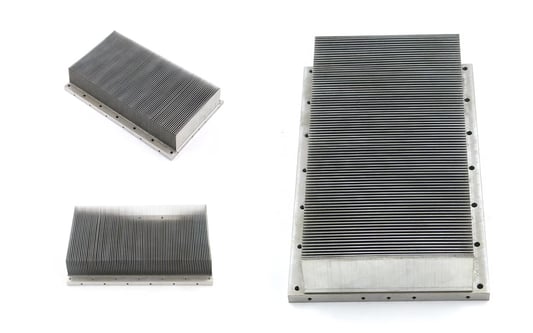

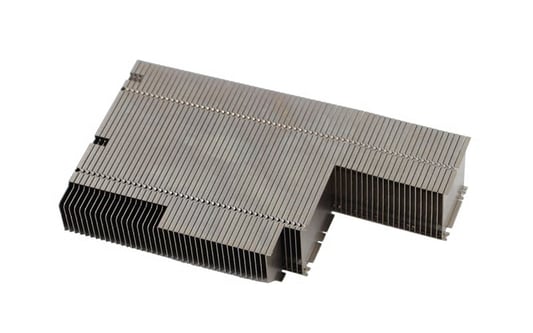

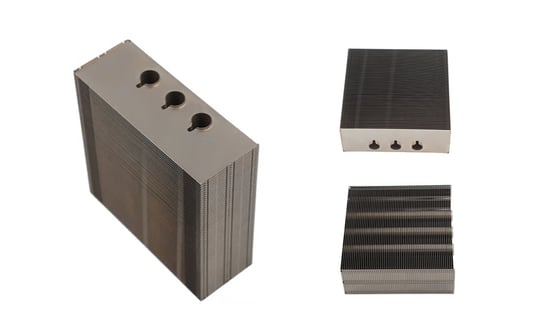

Efficient Heat TransferHeat pipes are an essential component in laptop cooling systems, as they help efficiently transfer heat away from the internal components. By utilizing the principle of phase change heat transfer, heat pipes can quickly move heat to areas where it can be dissipated, ensuring that the laptop remains cool during operation.Compact DesignOne of the key advantages of heat pipes in laptop cooling is their compact design. Heat pipes are small and lightweight, making them ideal for use in portable devices like laptops. Their ability to efficiently transfer heat also means that laptop manufacturers can design thinner and lighter devices without compromising on performance.Passive CoolingHeat pipes enable passive cooling in laptops, which is crucial for maintaining a quiet and energy-efficient operation. By utilizing the natural heat transfer process of the heat pipes, laptops can effectively dissipate heat without the need for noisy fans or complex cooling systems.Enhanced PerformanceEfficient cooling provided by heat pipes can significantly improve the overall performance of a laptop. By keeping internal components at optimal operating temperatures, heat pipes help prevent thermal throttling and ensure that the laptop can deliver consistent performance for demanding tasks such as gaming or video editing.Extended LifespanOverheating is one of the leading causes of hardware failures in laptops. Heat pipes play a crucial role in preventing overheating by effectively dissipating heat away from sensitive components. By maintaining lower operating temperatures, heat pipes help extend the lifespan of a laptop and reduce the risk of premature hardware failures.Thermal ManagementHeat pipes are an integral part of the thermal management system in laptops, helping to regulate the temperature of internal components. By efficiently transferring heat away from hotspots, heat pipes ensure that the laptop remains within safe operating temperatures, even during intensive tasks.Cost-Effective SolutionDespite their effectiveness, heat pipes are a cost-effective cooling solution for laptops. Their simple design and reliable operation make them a popular choice for laptop manufacturers looking to balance performance, reliability, and cost in their devices.Environmentally FriendlyHeat pipes contribute to the overall energy efficiency of laptops by enabling passive cooling. This not only reduces the energy consumption of the device but also helps minimize electronic waste by extending the lifespan of laptops through effective heat management.Compatibility with Slim DesignsThe compact and flexible nature of heat pipes makes them well-suited for use in slim and ultraportable laptop designs. Heat pipes can be easily integrated into the thin form factor of modern laptops, allowing manufacturers to deliver powerful and efficient devices without sacrificing portability.Future TrendsAs laptops continue to evolve with higher performance components, the role of heat pipes in cooling will become even more critical. Innovations in heat pipe technology, such as advanced materials and designs, will further enhance the cooling capabilities of laptops and help push the boundaries of what is possible in terms of performance and portability.Quote Inquirycontact us