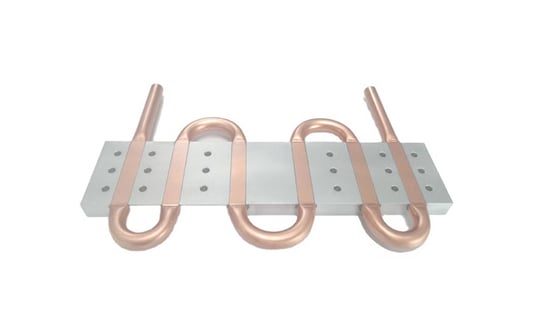

Understanding LED LifespanLEDs are known for their long lifespan, but various factors can impact their longevity. Heat buildup is a common issue in LEDs, leading to decreased performance and eventual failure. This is where heat pipes come in to play a crucial role in improving LED lifespan.Importance of Heat DissipationHeat dissipation is essential for maintaining optimal performance in LEDs. Excessive heat can cause the semiconductor materials in LEDs to degrade quickly, ultimately reducing their lifespan. By utilizing heat pipes, the heat generated by LEDs can be efficiently dissipated, ensuring their longevity.How Heat Pipes WorkHeat pipes are passive heat transfer devices that utilize the principle of phase change to efficiently transfer heat from one point to another. In the case of LEDs, heat pipes are used to draw heat away from the LED source and dissipate it to the surroundings, preventing overheating and extending the lifespan of the LEDs.Enhancing Thermal ManagementProper thermal management is crucial for LEDs to operate at their full potential. Heat pipes help in enhancing thermal management by effectively transferring heat away from the LED source, thereby reducing the risk of thermal runaway and improving overall performance and reliability.Extending LED LifespanBy incorporating heat pipes into LED lighting systems, the overall lifespan of the LEDs can be significantly extended. Heat pipes help in maintaining the optimal operating temperature of LEDs, preventing premature failure and ensuring consistent performance over an extended period.Reducing Maintenance CostsLEDs are known for their energy efficiency and long lifespan, but maintenance costs can still be a concern. By Improving LED Lifespan with Heat Pipes, maintenance costs can be minimized as the need for frequent replacements due to premature failure is reduced.Environmental ImpactExtending the lifespan of LEDs through the use of heat pipes not only benefits the users financially but also has a positive impact on the environment. By reducing the frequency of LED replacements, the overall waste generated from discarded LEDs is minimized, contributing to a more sustainable lighting solution.Applications in Various IndustriesThe use of heat pipes to improve LED lifespan has applications in various industries such as automotive, aerospace, and electronics. From automotive headlights to aircraft lighting systems, the incorporation of heat pipes ensures reliable and long-lasting LED performance in diverse applications.Future Trends in LED TechnologyAs LED technology continues to advance, the integration of heat pipes for improved thermal management is expected to become more prevalent. Manufacturers are increasingly recognizing the importance of heat dissipation in maximizing LED lifespan, driving innovation in heat pipe technology.ConclusionIn conclusion, the use of heat pipes plays a vital role in improving LED lifespan by enhancing thermal management and reducing heat buildup. By incorporating heat pipes into LED lighting systems, users can enjoy longer-lasting LEDs, reduced maintenance costs, and a more sustainable lighting solution.Quote Inquirycontact usFactory