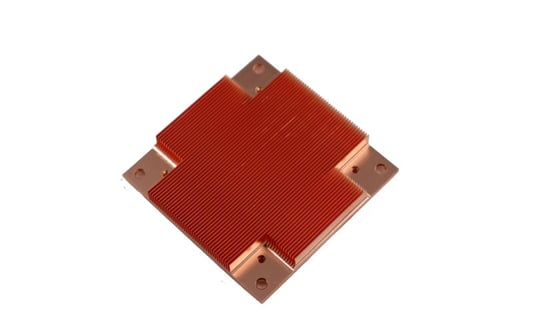

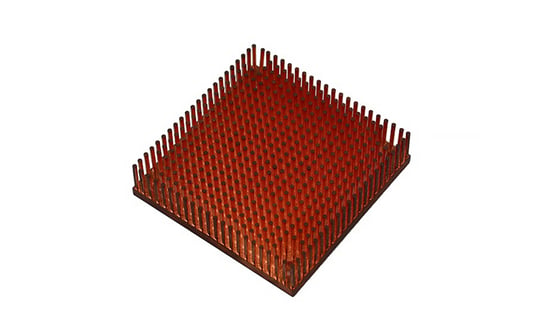

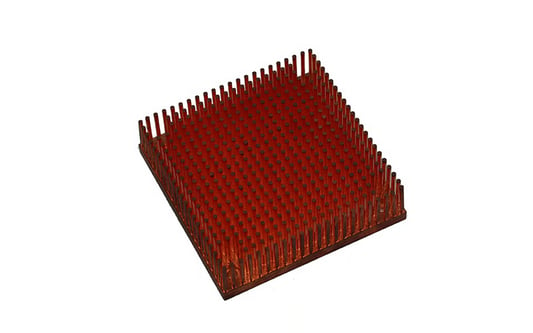

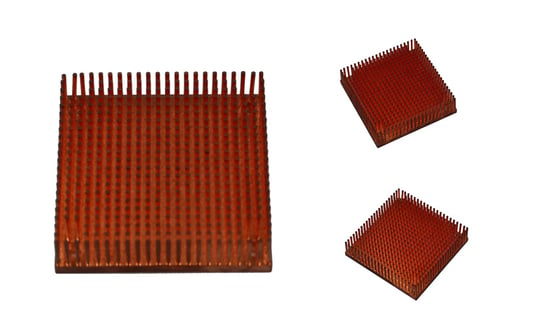

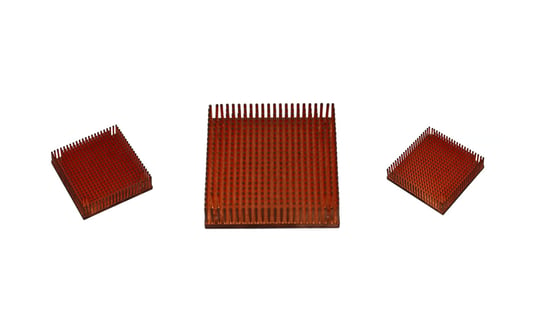

What are Stamped fin heat sinks?Stamped fin heat sinks are essential components used in various electronic devices to dissipate heat efficiently. They are typically made from aluminum or copper materials and feature fins that are stamped or formed to increase the surface area for better heat dissipation.Advantages of Stamped Fin Heat SinksStamped fin heat sinks offer several advantages compared to other types of heat sinks. They are cost-effective to manufacture in large quantities, lightweight, and provide excellent thermal performance due to their increased surface area. Additionally, they can be customized to meet specific design requirements for different electronic devices.Efficient Heat DissipationOne of the primary functions of stamped fin heat sinks is to dissipate heat generated by electronic components, such as processors, transistors, and power modules. The stamped fins create multiple pathways for heat to transfer away from the component, thereby preventing overheating and ensuring optimal performance of the device.Applications of Stamped Fin Heat SinksStamped fin heat sinks are widely used in various industries, including automotive, aerospace, telecommunications, and computer hardware. They are commonly found in power supplies, amplifiers, LED lighting systems, and other electronic devices that require efficient cooling solutions to maintain their reliability and longevity.Customization OptionsManufacturers of stamped fin heat sinks offer customization options to meet the specific requirements of different electronic devices. This includes the ability to adjust the size, shape, and spacing of the fins, as well as the choice of materials and surface finishes to optimize heat dissipation and thermal performance.Thermal Management BenefitsStamped fin heat sinks play a crucial role in thermal management by effectively removing heat from sensitive electronic components. They help maintain the operating temperature within safe limits, thereby improving the overall reliability and lifespan of the device.Cost-Effective SolutionStamped fin heat sinks are a cost-effective solution for thermal management in electronic devices. Their simple yet efficient design allows for mass production at a low cost, making them ideal for applications where budget constraints are a concern without compromising on performance.Factors to ConsiderWhen selecting stamped fin heat sinks for a specific application, it is essential to consider factors such as thermal resistance, airflow restrictions, space constraints, and mounting options. Proper selection and installation of heat sinks are critical to ensuring optimal cooling performance and device reliability.Future Trends in Heat Sink DesignAs technology continues to advance, the demand for more efficient and compact heat sinks is on the rise. Manufacturers are exploring innovative design techniques and materials to enhance the performance of stamped fin heat sinks and meet the evolving thermal management needs of modern electronic devices.ConclusionIn conclusion, stamped fin heat sinks are indispensable components for efficient thermal management in electronic devices. Their high thermal conductivity, lightweight construction, and cost-effective manufacturing make them a preferred choice for a wide range of applications where heat dissipation is critical for device performance and longevity.Quote Inquirycontact us