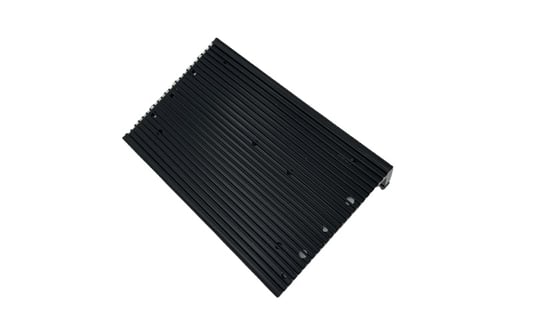

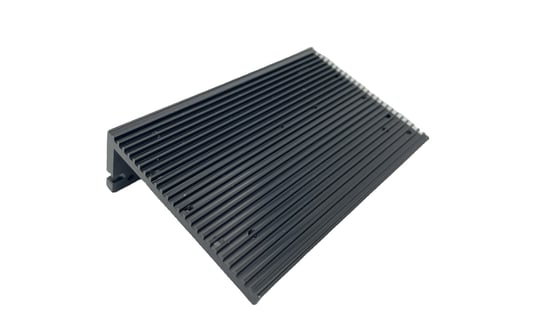

Understanding Heat Sink Module IntegrationHeat sink modules play a crucial role in managing the temperature of electronic devices by dissipating heat effectively. The integration of these modules is essential for ensuring optimal performance and longevity of electronic devices.Design Considerations for Heat Sink Module IntegrationWhen designing heat sink module integration, factors such as thermal conductivity, size, shape, and material compatibility must be taken into consideration. Designing with these considerations in mind can help minimize integration challenges.Compatibility with Electronic ComponentsOne of the challenges in heat sink module integration is ensuring compatibility with various electronic components. Different components may have different heat dissipation requirements, which must be taken into account during integration.Optimizing Airflow for Heat DissipationEfficient heat dissipation is crucial for the proper functioning of electronic devices. Ensuring proper airflow and ventilation around the heat sink modules is essential to optimize heat dissipation and prevent overheating.Thermal Management StrategiesEffective thermal management strategies are essential for overcoming Heat Sink Module Integration Challenges. This includes proper placement of heat sink modules, using thermal interface materials, and implementing heat pipes for enhanced heat transfer.Testing and Validation ProcessesThorough testing and validation processes are crucial for ensuring the successful integration of heat sink modules. Testing for thermal performance, compatibility, and reliability is essential to address any integration issues before deployment.Overcoming Size and Space ConstraintsSpace constraints within electronic devices can pose challenges for heat sink module integration. Designing compact and efficient heat sink modules that can fit within the given space is essential for overcoming this challenge.Material Selection for Heat Sink ModulesThe choice of materials for heat sink modules is critical for effective heat dissipation. Selecting materials with high thermal conductivity and compatibility with electronic components is crucial for successful integration.Addressing Thermal ResistanceThermal resistance can impact the efficiency of heat sink module integration. Minimizing thermal resistance through proper design, material selection, and thermal management strategies is essential for optimal heat dissipation.Future Trends and InnovationsAdvancements in heat sink module technologies continue to address integration challenges. Innovations such as liquid cooling systems, advanced thermal interface materials, and integrated heat sink designs are shaping the future of heat sink module integration.Quote Inquirycontact usFactory