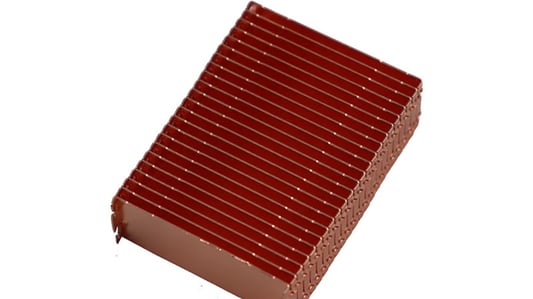

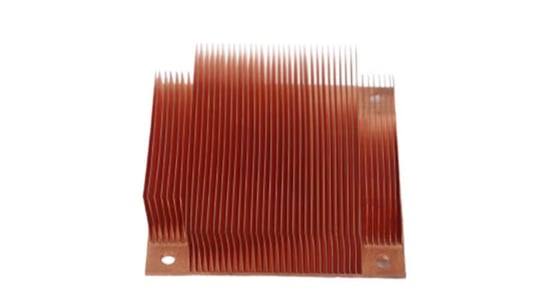

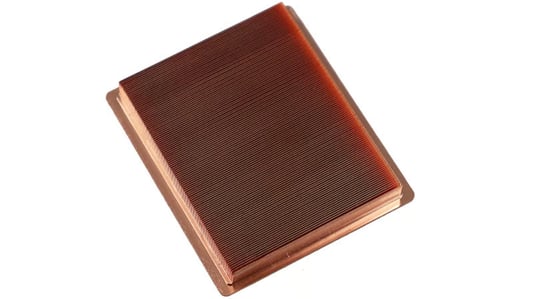

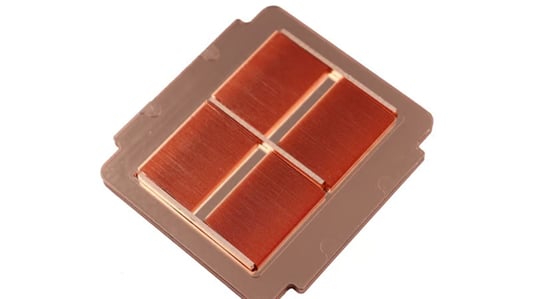

The Science Behind heat sink with heat pipeThe heat sink with heat pipe is a revolutionary technology that has dramatically improved the efficiency of thermal management in electronic devices. Heat pipes are sealed copper tubes containing a small amount of liquid, typically water or a refrigerant. When the device heats up, the liquid evaporates, carrying heat away from the source. The vapor then condenses back into liquid form, releasing the heat in a different location. This process allows for rapid and efficient heat transfer, making heat sinks with heat pipes one of the most effective cooling solutions available.Benefits of Using Heat Sinks with Heat PipesOne of the key advantages of heat sinks with heat pipes is their ability to dissipate heat quickly and effectively, leading to improved performance and longevity of electronic components. Additionally, these cooling systems are lightweight and compact, making them ideal for small devices with limited space for traditional cooling solutions. Heat sinks with heat pipes are also durable and reliable, requiring minimal maintenance and offering a long operational lifespan.Application of Heat Sinks with Heat PipesHeat sinks with heat pipes are commonly used in a variety of electronic devices, including laptops, desktop computers, LED lighting systems, and smartphones. These cooling solutions are also found in industrial applications such as power electronics, telecommunications equipment, and automotive systems. The versatility and efficiency of heat sinks with heat pipes make them a popular choice for cooling high-power electronic components in a wide range of industries.Design Considerations for Heat Sinks with Heat PipesWhen designing a heat sink with heat pipes, several factors must be taken into account to ensure optimal performance. The size and shape of the heat sink, as well as the number and placement of heat pipes, can impact the overall cooling efficiency. The thermal conductivity of the materials used and the effectiveness of the interface between the heat source and the heat sink also play a significant role in determining the cooling capacity of the system.Types of Heat Pipe TechnologiesThere are several types of heat pipe technologies used in heat sinks, including grooved heat pipes, sintered powder heat pipes, and loop heat pipes. Grooved heat pipes feature internal grooves that enhance capillary action, allowing for better liquid circulation and heat transfer. Sintered powder heat pipes use a porous wick structure to facilitate the movement of the liquid phase. Loop heat pipes, on the other hand, utilize a closed loop system with a secondary loop for fluid circulation, enabling effective heat removal over longer distances.Challenges and Limitations of Heat Sinks with Heat PipesWhile heat sinks with heat pipes offer significant advantages in terms of thermal management, there are some challenges and limitations to consider. For example, the effectiveness of heat pipes can be affected by orientation, gravity, and operating temperature range. Controlling condensation and preventing vapor blockage are also important considerations when designing heat sinks with heat pipes for specific applications. Additionally, the cost of implementing heat pipe technology may be a factor for some manufacturers.Future Trends in Heat Sink with Heat Pipe TechnologyAs technology continues to advance, heat sink with heat pipe technology is expected to evolve to meet the increasing demands for efficient thermal management in electronic devices. Innovations such as enhanced wick structures, advanced materials, and improved manufacturing processes are driving the development of more efficient and cost-effective heat sink solutions. The integration of heat pipes with other cooling technologies, such as fans and liquid cooling systems, is also likely to become more widespread in the future.Environmental Impact of Heat Sinks with Heat PipesHeat sinks with heat pipes play a crucial role in reducing energy consumption and extending the lifespan of electronic devices by efficiently dissipating heat. By improving thermal management, these cooling solutions help lower operating temperatures, thereby reducing the need for energy-intensive cooling mechanisms. This not only contributes to lower energy costs but also minimizes the environmental impact of electronic devices by promoting energy efficiency and sustainability.Industry Applications and Case StudiesNumerous industries have benefited from the implementation of heat sinks with heat pipes in their electronic systems. For example, the aerospace industry relies on these cooling solutions to maintain optimal thermal performance in avionics and satellite systems. In the automotive sector, heat sinks with heat pipes are used to regulate temperatures in electric vehicles and hybrid cars. Case studies showcasing the effectiveness of heat sink technology in different applications demonstrate the versatility and reliability of these cooling systems.Choosing the Right Heat Sink with Heat Pipe SolutionWhen selecting a heat sink with heat pipe solution for your electronic device or industrial application, it is essential to consider factors such as thermal design requirements, operating conditions, and space constraints. Consulting with a thermal design engineer or heat sink manufacturer can help you determine the most suitable cooling solution for your specific needs. By choosing the right heat sink with heat pipe technology, you can ensure efficient thermal management and optimal performance of your electronic systems.Quote InquiryContact us