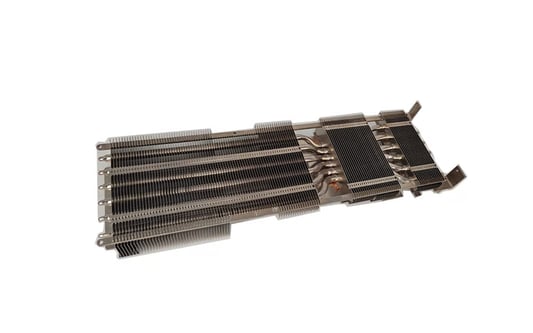

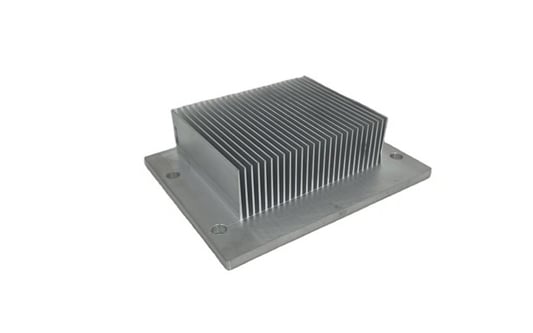

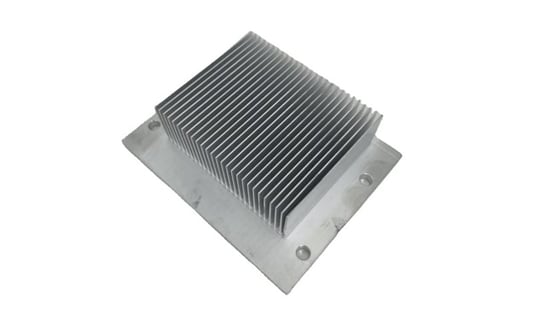

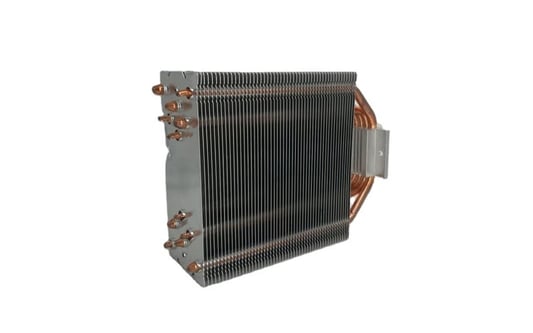

As technology advances, the demand for efficient cooling solutions for electronic devices continues to grow. One such innovation is the GB300 direct chip cooling technology, which offers a range of benefits for various applications.Enhanced Thermal PerformanceOne of the key advantages of GB300 direct chip cooling is its ability to provide enhanced thermal performance for electronic devices. By directly cooling the chip, this technology helps to dissipate heat more effectively, ensuring optimal performance and reliability.Improved Energy EfficiencyGB300 direct chip cooling technology is also known for its improved energy efficiency compared to traditional cooling methods. By targeting the source of heat directly, this technology reduces the overall energy consumption of the device, resulting in cost savings and environmental benefits.Compact DesignAnother benefit of GB300 direct chip cooling is its compact design, making it ideal for applications where space is limited. This technology can be easily integrated into small electronic devices without compromising on cooling performance.Extended Component LifespanBy maintaining lower operating temperatures through efficient cooling, GB300 direct chip cooling technology helps to extend the lifespan of electronic components. This can lead to reduced maintenance costs and increased reliability over time.Silent OperationUnlike some traditional cooling solutions that produce noise during operation, GB300 direct chip cooling technology operates silently. This makes it suitable for noise-sensitive environments and ensures a quiet user experience.Flexible ApplicationGB300 direct chip cooling technology is highly versatile and can be used in a wide range of applications, from consumer electronics to industrial equipment. Its flexibility makes it a popular choice for manufacturers looking to improve the cooling performance of their products.Quick and Easy InstallationInstalling GB300 direct chip cooling technology is a quick and straightforward process, making it convenient for manufacturers and end-users alike. This plug-and-play solution requires minimal setup and can be easily integrated into existing devices.ScalabilityWhether you need cooling solutions for a single device or an entire data center, GB300 direct chip cooling technology offers scalability to meet your specific requirements. This technology can be scaled up or down to accommodate different cooling needs.Cost-Effective SolutionWith its energy-efficient design and long-term benefits, GB300 direct chip cooling technology offers a cost-effective solution for cooling electronic devices. By reducing energy consumption and maintenance costs, this technology provides a high return on investment.Future of Cooling TechnologyAs the demand for efficient and reliable cooling solutions continues to rise, GB300 direct chip cooling technology is set to play a crucial role in shaping the future of cooling technology. With its numerous benefits and versatile applications, this technology is expected to drive innovation in various industries.Quote Inquirycontact usFactory