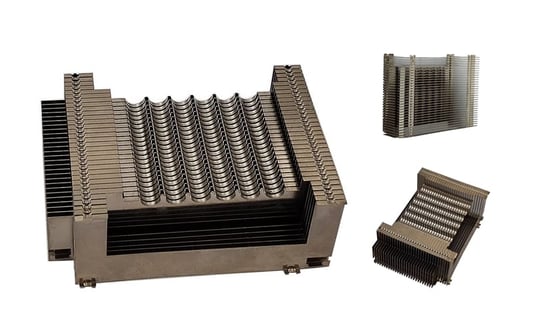

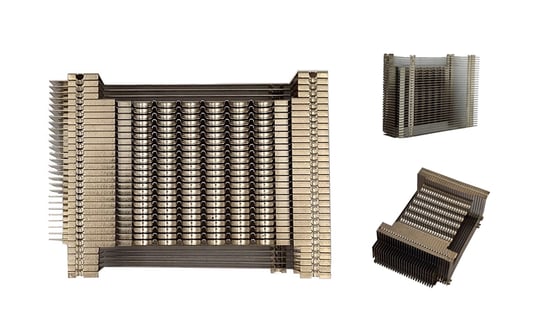

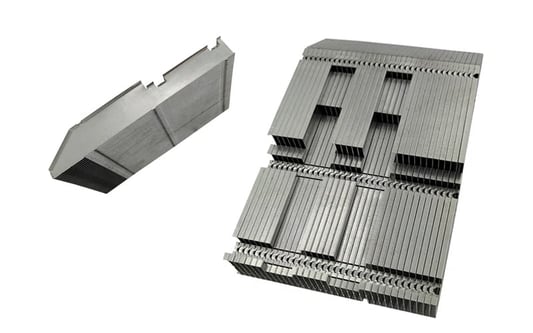

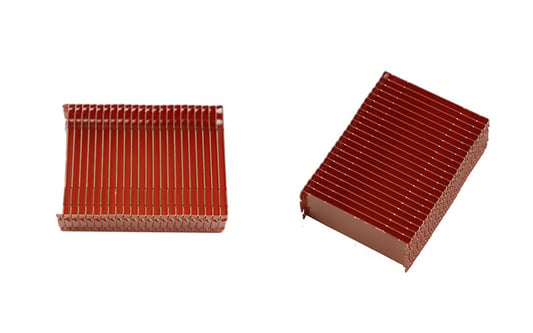

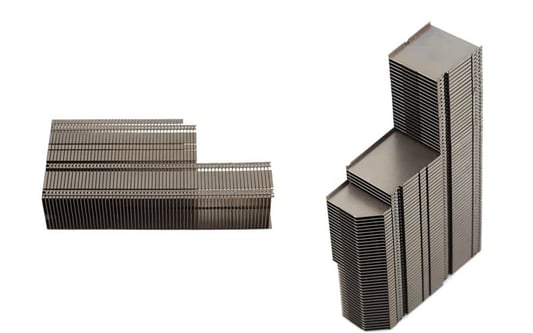

Understanding Skived Heat SinksSkived heat sinks are known for their high thermal conductivity and efficient heat dissipation abilities. They are made by carving a solid block of aluminum or copper to create a finned structure. This process allows for intricate designs and precise specifications to be met, making skived heat sinks ideal for applications where space is limited and thermal management is critical.Exploring Bonded Heat SinksBonded heat sinks are constructed by attaching fins to a base using adhesive or solder. This method is cost-effective and allows for customization in terms of material and fin density. Bonded heat sinks are commonly used in consumer electronics and automotive industries where moderate thermal performance is sufficient.Examining Forged Heat SinksForged heat sinks are manufactured by shaping a solid block of metal under high pressure and heat. This process results in a stronger and more durable heat sink compared to skived or bonded types. Forged heat sinks are often used in rugged or high-power applications where reliability and thermal performance are crucial.Thermal Conductivity and EfficiencyWhen Comparing Skived, Bonded, and Forged Heat Sinks, thermal conductivity is a key factor to consider. Skived heat sinks typically offer the highest thermal conductivity due to their solid construction, followed by forged heat sinks. Bonded heat sinks may have slightly lower thermal conductivity but are still effective for many applications.Cost and Manufacturing ProcessSkived heat sinks tend to be more expensive to manufacture compared to bonded heat sinks due to the precision machining involved. Forged heat sinks fall in between, offering a balance between cost and performance. When considering cost-effectiveness, bonded heat sinks are often the preferred choice for mass production.Customization and Design FlexibilitySkived heat sinks allow for intricate designs and precise specifications to be met, making them ideal for custom applications. Bonded heat sinks offer some level of customization in terms of fin density and material, while forged heat sinks are limited in design flexibility but excel in strength and durability.Applications in Electronics and Automotive IndustriesSkived heat sinks are commonly used in high-performance computing, telecommunications, and aerospace industries where thermal management is critical. Bonded heat sinks find applications in consumer electronics, LED lighting, and automotive cooling systems. Forged heat sinks are preferred in industrial equipment, power supplies, and electric vehicle components.Environmental Considerations and SustainabilityWhen it comes to environmental impact, skived and forged heat sinks have a higher carbon footprint compared to bonded heat sinks due to the manufacturing processes involved. Bonded heat sinks, with their simpler manufacturing process and potentially recyclable materials, are a more sustainable option for companies looking to reduce their environmental impact.Durability and LongevityIn terms of durability, forged heat sinks are the most robust and long-lasting option due to their solid construction. They can withstand harsh environments and high thermal loads without compromising performance. Skived heat sinks are also durable but may not be as strong as forged heat sinks. Bonded heat sinks have a good balance of durability and cost-effectiveness.Choosing the Right Heat Sink for Your ApplicationWhen it comes to selecting the right heat sink for your specific application, consider factors such as thermal conductivity, cost, customization options, environmental impact, and durability. Skived, bonded, and forged heat sinks each have their strengths and weaknesses, so it's important to weigh these factors against your requirements before making a decision.Quote Inquirycontact us