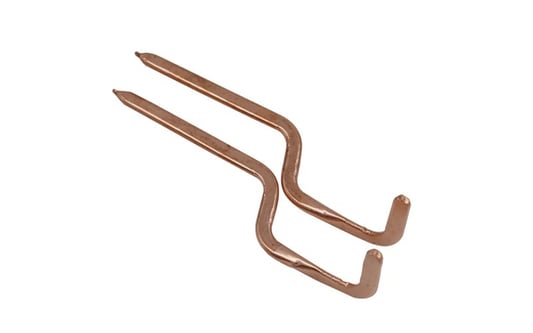

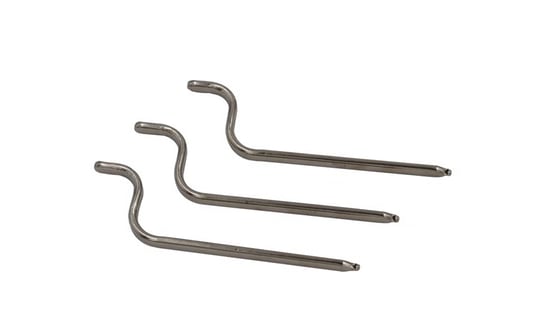

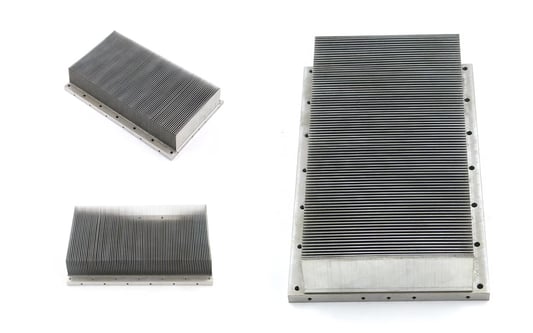

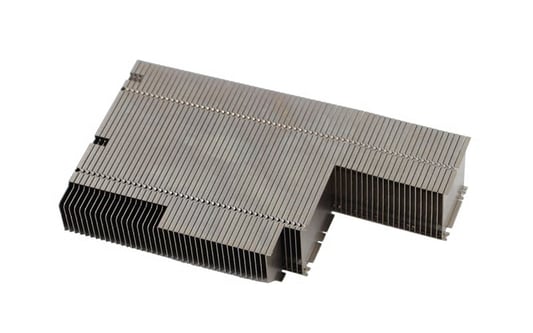

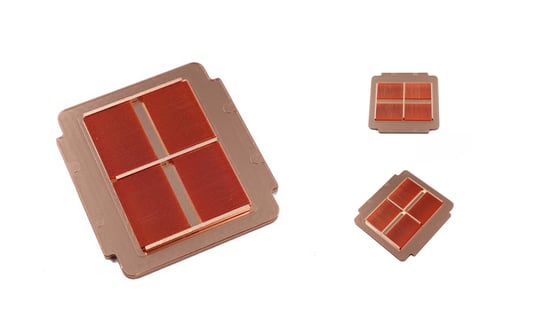

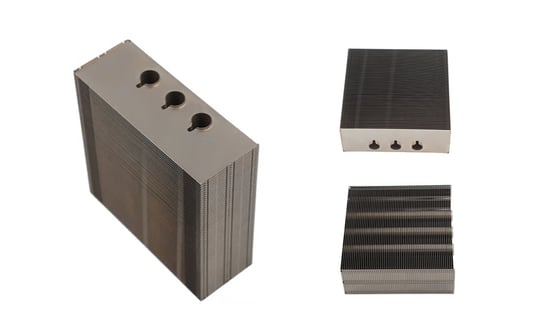

The Basics of Heat PipesHeat pipes are essential components in passive thermal management systems, designed to efficiently transfer heat from one location to another using phase change principles. These devices consist of a sealed hollow tube made of a thermally conductive material, such as copper or aluminum, which contains a working fluid. When heat is applied to one end of the heat pipe, the working fluid vaporizes, carrying thermal energy to the cooler end where it condenses and releases heat. This process enables heat pipes to effectively dissipate heat away from sensitive components.Operating Principles of Heat PipesHeat pipes operate on the principles of evaporation and condensation, utilizing the latent heat of vaporization to transfer heat with minimal temperature difference. By selecting a suitable working fluid with a low boiling point, heat pipes can efficiently transfer heat over long distances while maintaining a consistent temperature gradient. This property makes them ideal for use in passive thermal management systems where cooling without active mechanical components is preferred.Types of Heat PipesThere are several types of heat pipes available, including traditional copper heat pipes, loop heat pipes, and pulsating heat pipes. Each type has its unique design and operating characteristics, making them suitable for different applications. Copper heat pipes are commonly used in electronic devices for cooling purposes, while loop heat pipes are favored for space applications due to their reliability and efficiency in microgravity environments.Advantages of Heat Pipes in Thermal ManagementHeat pipes offer numerous advantages in thermal management, such as high heat transfer efficiency, compact size, and passive operation. Their ability to transport heat over long distances with minimal thermal resistance makes them ideal for cooling applications where space and weight are critical constraints. Additionally, heat pipes have a long operating life and require minimal maintenance, making them a cost-effective solution for thermal management.Applications of Heat Pipes in ElectronicsHeat pipes are widely used in electronics for cooling high-power components, such as CPUs, GPUs, and power amplifiers. By incorporating heat pipes into the design of electronic devices, engineers can effectively dissipate heat away from critical components, ensuring optimal performance and reliability. Heat pipes are also utilized in LED lighting, battery thermal management, and aerospace applications for efficient heat transfer.Thermal Performance of Heat PipesThe thermal performance of heat pipes is influenced by several factors, including the working fluid, wick structure, operating temperature range, and heat pipe geometry. By optimizing these parameters, engineers can improve the heat transfer efficiency and thermal conductivity of heat pipes, ensuring effective thermal management in various applications. Proper design and selection of heat pipes are crucial to achieving optimal performance and reliability.Challenges in Heat Pipe DesignDespite their many advantages, heat pipes also present certain challenges in design and implementation. Issues such as fluid compatibility, operating temperature limits, and thermal resistance can impact the performance of heat pipes in specific applications. Proper testing and validation are essential to ensure the reliable operation of heat pipes under varying environmental conditions and thermal loads.Future Trends in Heat Pipe TechnologyAdvancements in heat pipe technology are focused on enhancing thermal performance, increasing reliability, and extending the operating temperature range. Researchers are exploring new materials, innovative wick structures, and advanced manufacturing techniques to improve the efficiency and durability of heat pipes. The integration of heat pipes in emerging technologies, such as electric vehicles, renewable energy systems, and 5G infrastructure, will drive further innovation in passive thermal management solutions.Environmental Impact of Heat PipesHeat pipes offer a sustainable cooling solution by reducing energy consumption and carbon emissions associated with traditional active cooling systems. By utilizing passive thermal management techniques with heat pipes, industries can achieve significant energy savings and minimize their environmental footprint. The recyclability and long service life of heat pipes make them an eco-friendly choice for thermal management applications.ConclusionIn conclusion, heat pipes play a vital role in passive thermal management by efficiently transferring heat away from sensitive components using phase change principles. These versatile devices offer numerous advantages, including high heat transfer efficiency, compact size, and long-term reliability. By understanding the operating principles and applications of heat pipes, engineers can design innovative thermal management solutions that meet the demands of modern technologies while reducing energy consumption and environmental impact.Quote Inquirycontact us

03. June, 2025