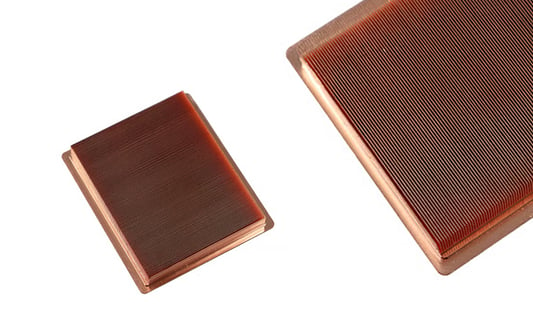

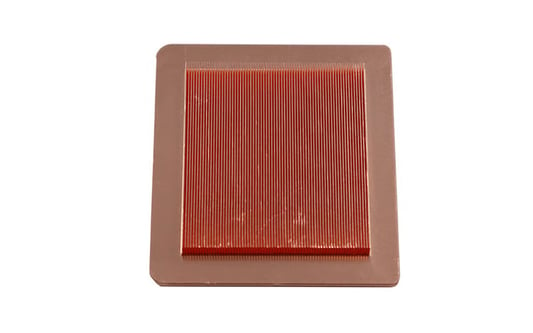

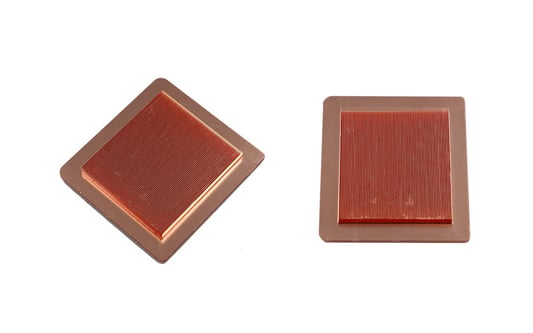

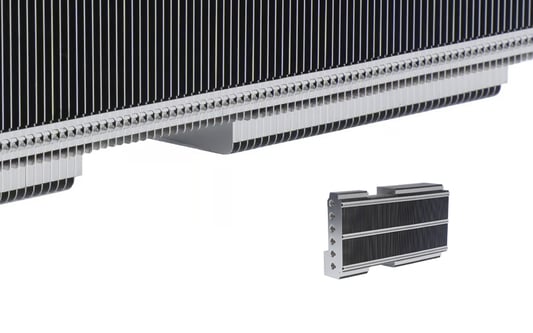

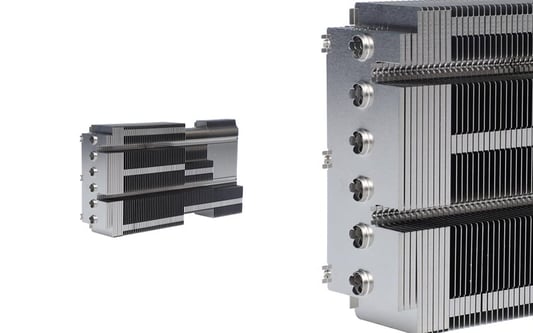

Introduction to Heat SinksHeat sinks are essential components in electronic devices that help dissipate heat generated by the components. They come in various shapes and sizes, with skived and extruded being two common types used in the industry.Skived Heat Sinks: OverviewSkived heat sinks are manufactured by cutting a solid block of metal into thin fins. These fins are then skived or sliced to create a larger surface area for better heat dissipation. They are known for their high thermal conductivity and efficiency in cooling electronic devices.Extruded Heat Sinks: OverviewExtruded heat sinks, on the other hand, are produced by pushing a metal or alloy through a die to create the desired shape. They are cost-effective and easy to manufacture in large quantities. However, they may not have the same level of thermal performance as skived heat sinks.Thermal PerformanceWhen it comes to thermal performance, skived heat sinks are typically more effective at dissipating heat compared to extruded heat sinks. This is due to the larger surface area created by the skiving process, allowing for better heat transfer to the surrounding environment.Cost ConsiderationsExtruded heat sinks are generally more cost-effective to produce than skived heat sinks. The extrusion process is efficient and can be automated for mass production, resulting in lower manufacturing costs. However, the lower cost may come at the expense of thermal performance.Material OptionsBoth skived and extruded heat sinks can be made from various materials, including aluminum, copper, and steel. Aluminum is a popular choice for its lightweight and good thermal conductivity. Copper is another common option known for its excellent heat transfer properties.Customization and Design FlexibilitySkived heat sinks offer more design flexibility and customization options compared to extruded heat sinks. The skiving process allows for intricate designs and complex geometries to optimize thermal performance for specific electronic applications.Application ConsiderationsThe choice between skived and extruded heat sinks depends on the specific requirements of the electronic device and its operating conditions. Skived heat sinks are ideal for high-performance applications where thermal efficiency is crucial, while extruded heat sinks may be more suitable for cost-sensitive projects.Environmental ImpactIn terms of environmental impact, both skived and extruded heat sinks can be recycled and repurposed at the end of their lifecycle. Choosing a material with a lower carbon footprint, such as aluminum, can further reduce the environmental impact of heat sink production.Conclusion: Making the Right ChoiceWhen it comes to choosing between skived and extruded heat sinks, it ultimately depends on the specific requirements of the electronic device and the balance between thermal performance, cost, and design flexibility. Consider consulting with a heat sink expert to determine the best option for your project.Quote Inquirycontact us