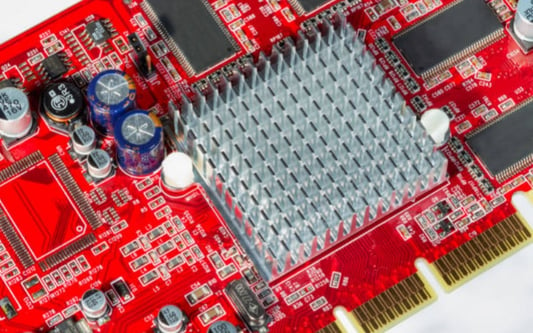

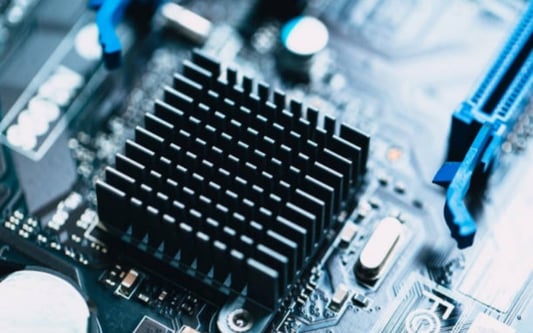

The Purpose of a Heat Sink: Keeping Your Electronics CoolIntroduction: As technology continues to advance at a rapid pace, devices are becoming smaller, faster, and more powerful. However, these advancements also result in a significant increase in heat generation. Excessive heat can damage electronic components and compromise their performance. That's where heat sinks come into play. In this article, we will explore the purpose of a heat sink and how it helps to keep your electronics cool.1. Understanding Heat Generation in ElectronicsElectronic devices, such as CPUs, GPUs, and power amplifiers, generate heat as a byproduct of their operation. This heat is primarily produced due to resistive losses in semiconductor materials and the flow of electrical current. The more power a device consumes or the higher the frequency at which it operates, the more heat it generates. Without appropriate cooling mechanisms, this heat can accumulate and lead to device failures or reduced performance.2. What Exactly is a Heat Sink?A heat sink is a passive cooling device that helps dissipate heat from electronic components by increasing their surface area. It is typically made of a thermally conductive material, such as aluminum or copper, which has high thermal conductivity. Heat sinks are designed to absorb and transfer heat away from the electronic component to the surrounding environment, allowing it to cool down.3. How Does a Heat Sink Work?A heat sink works based on the principle of thermal conduction. When an electronic component, such as a CPU, generates heat, it transfers that heat to the heat sink through direct contact. The heat sink then spreads the heat across its larger surface area. This increased surface area enables better heat dissipation into the surrounding air or a cooling medium, such as a fan or liquid cooling system.4. Benefits of Using a Heat SinkUsing a heat sink offers several advantages in electronic devices:Temperature Regulation: Heat sinks help regulate the temperature of electronic components, preventing them from overheating and causing damage.Improved Performance: By keeping electronic components cool, heat sinks help maintain their optimal operating conditions, ensuring consistent and reliable performance.Extended Lifespan: Excessive heat can significantly reduce the lifespan of electronic components. Heat sinks help prolong their lifespan by dissipating heat effectively.Compact Design: Heat sinks allow for the design of smaller, more compact electronic devices by efficiently managing heat dissipation.5. Different Types of Heat SinksHeat sinks come in various shapes and sizes, each designed to suit different electronic components and cooling requirements:Finned Heat Sinks: These are the most common type of heat sinks, featuring a series of fins that increase the surface area for better heat dissipation.Pin Heat Sinks: Pin heat sinks consist of an array of pins that extend from the base, providing increased surface area and enabling efficient heat transfer.Plate Heat Sinks: Plate heat sinks are flat, rectangular heat sinks that are ideal for cooling components with larger surface areas.Liquid Heat Sinks: Liquid heat sinks use a liquid coolant, such as water or oil, to transfer heat away from the electronic component more effectively.6. Factors to Consider When Choosing a Heat SinkWhen selecting a heat sink for your electronic device, several factors need to be considered:Thermal Conductivity: The thermal conductivity of the heat sink material determines how efficiently it can transfer heat.Surface Area: A larger surface area allows for better heat dissipation, so choosing a heat sink with the appropriate surface area is crucial.Airflow: The availability of airflow, either through natural convection or forced convection, impacts the cooling efficiency of the heat sink.Mounting Method: The heat sink's mounting method should be compatible with the electronic component to ensure efficient heat transfer.7. Additional Heat Dissipation TechniquesWhile heat sinks are an essential cooling solution, they are often used in conjunction with other techniques to maximize heat dissipation:Thermal Interface Materials (TIM): TIMs, such as thermal paste or thermal pads, are applied between the electronic component and the heat sink to improve thermal conductivity and fill any air gaps.Cooling Fans: Fans are commonly used in conjunction with heat sinks to increase airflow and enhance heat dissipation.Liquid Cooling Systems: Liquid cooling systems, which circulate a coolant through the heat sink, offer more efficient heat transfer than air cooling.8. Real-Life Applications of Heat SinksHeat sinks find applications in various electronic devices, including:Computers: CPUs and GPUs in computers require heat sinks to prevent overheating and maintain optimal performance.LED Lighting: Heat sinks are crucial in LED lighting systems to dissipate the heat generated by the LED bulbs.Power Amplifiers: Power amplifiers, used in audio systems, benefit from heat sinks to manage heat generated during high-power operations.Solar Panels: Heat sinks are used in solar panels to cool down the photovoltaic cells, improving their efficiency and longevity.9. Advances in Heat Sink TechnologyOver the years, heat sink technology has evolved to meet the increasing demands of modern electronics. Some notable advancements include:Nanofluids: Nanofluids, which contain nanoparticles, offer improved thermal conductivity and enable more efficient heat transfer.Microchannels: Heat sinks with microchannels provide enhanced heat dissipation by increasing the surface area available for heat transfer.Phase Change Materials: Phase change materials, such as waxes or gels, absorb heat during phase transitions, effectively managing temperature fluctuations.10. ConclusionConclusion: Heat sinks play a vital role in maintaining the optimal operating conditions of electronic components. By dissipating heat and preventing overheating, heat sinks help ensure the longevity, performance, and reliability of various electronic devices. Choosing the right heat sink and employing appropriate cooling techniques is essential to maximize the efficiency of heat dissipation and protect your valuable electronics.Quote InquiryContact us!