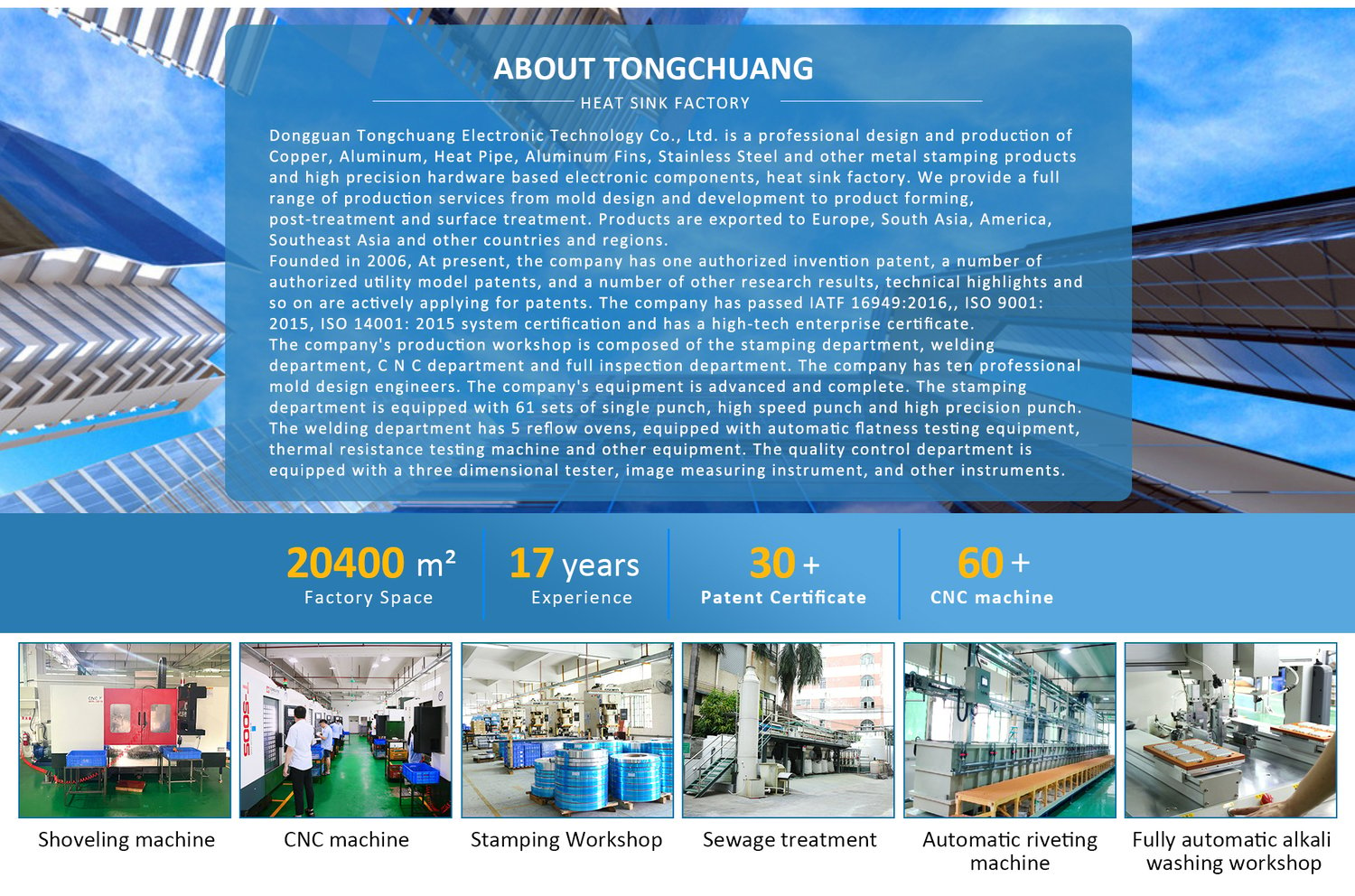

Dongguan Tongchuang Elec.Tech. Co.,Ltd is a professional design and production of Copper, Aluminum, Heat Pipe, Aluminum Fins, Stainless Steel, and other metal stamping products and high precision hardware-based electronic components, and heat sink factory. We provide a full range of production services from mold design and development to product forming, post-treatment and surface treatment. Products are exported to Europe, South Asia, America, Southeast Asia and other countries and regions.

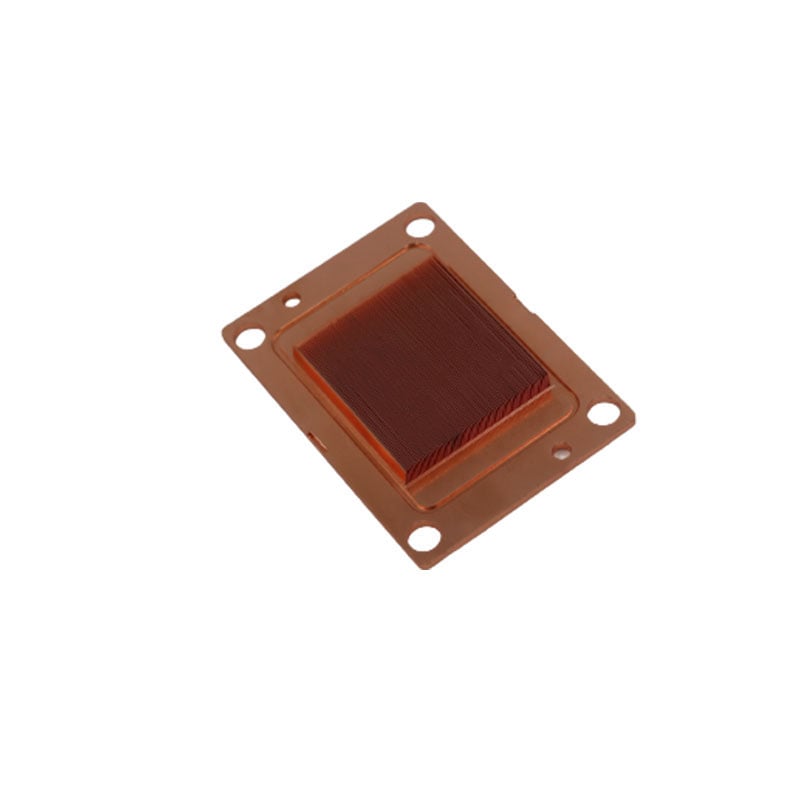

Material:Aluminum/Copper

Process:Skiving

Tolerance:Customer Requested

Flatness:Customer Requested

Surface Treatment:

Aluminum:Anodizing/Conversion Coating/Nickel Plating

Copper:Anti-Oxidation/Nickel Plating

Introducing our revolutionary Anti-Oxidation CNC Milling Skived Copper Heatsink! Designed for maximum performance and durability, this skiving heat sink is perfect for the manufacturing industry. It boasts exceptional heat dissipation and prevents oxidation, ensuring optimal functionality and longevity. With its CNC milling technology, our heatsink guarantees precision and accuracy. Experience unparalleled efficiency and reliability with our Anti-Oxidation CNC Milling Skived Copper Heatsink. Stay ahead of the competition and elevate your manufacturing process to new heights!

The shovel tooth heat sink has a higher heat sink density and improves heat sink performance;

The height of the blades of the shovel tooth heat sink can reach 120mm, which fully meets the production needs of most heat sinks;

The teeth of the shovel tooth heat sink can be made thinner, up to 0.05mm-2mm, which can make the heat sink lighter;

The shovel tooth heat sink is shoveled on the original material, so the heat sink efficiency is not damaged, reaching 100% of the heat sink efficiency of the original material, and there will be no risk of loosening and falling off, improving the reliability of machine operation;

The shovel tooth heat sink has high compatibility and great possibilities for post-processing. It can also be used with processes such as buried copper pipes to improve heat sink performance;

The performance and efficiency of shovel tooth machines have been continuously improved, and the materials of shovel teeth have been continuously improved, making them suitable for mass production.

Yes, send us the drawing and surface treatment requirements, our engineer will evaluate your drawing and give you a quotation.

Yes, we will not release your design to third party unless with your permission. And we can sign the NDA before you send the drawing.

We will charge the tooling cost, but the tooling cost can be refunded when mass production.

MOQ will be set according to your product and drawing requirements, but generally we will not set MOQ.

We can provide sample production, and the mass production will be carried out after the sample is confirmed to you.

Please rest assured that all our products are QC inspected and accepted with inspection report before delivery and generally there will no non-conformance; in case of non- conformance, please contact us immediately, take some pictures, we will check on the problems and have them reworked or repaired at the first time , the resulting transportation costs borne by our company.