The Advantages and Applications of Zipper Fin Heat Sinks

Heat sinks play a vital role in managing the temperature of electronic devices, preventing them from overheating and ensuring optimal performance. One type of heat sink that has gained popularity in recent years is the zipper fin heat sink. This article delves into the various aspects of zipper fin heat sinks, including their design, advantages, and applications.

What are Zipper Fin Heat Sinks?

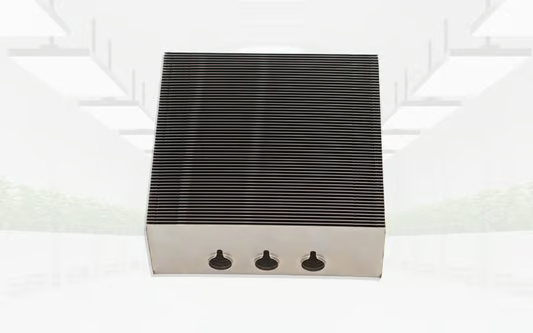

Zipper fin heat sinks, also known as zipper fin coolers, are innovative cooling solutions designed to dissipate heat efficiently in electronic devices. They feature a unique fin design that resembles a zipper, with alternating rows of fins that are interlocked together. This design maximizes the surface area available for heat dissipation, resulting in improved cooling performance.

The Design and Functionality of Zipper Fin Heat Sinks

The design of zipper fin heat sinks is what sets them apart from traditional heat sink designs. The interlocking fin structure creates a larger heat transfer surface area, allowing for better heat dissipation. This design also increases the contact area between the heat sink and the surrounding air, facilitating the transfer of heat from the device to the environment.

Zipper fin heat sinks are typically made from high-conductivity materials such as aluminum or copper. These materials have excellent thermal conductivity properties, ensuring efficient heat transfer. The fins are usually tightly packed together to maximize the surface area while maintaining structural integrity.

The Advantages of Zipper Fin Heat Sinks

Zipper fin heat sinks offer several advantages over traditional heat sink designs. Firstly, their unique fin design allows for a larger surface area, leading to enhanced heat dissipation. This results in lower operating temperatures for electronic devices, improving their overall performance and reliability.

Additionally, zipper fin heat sinks can be customized to fit specific device requirements. Manufacturers can adjust the size, shape, and number of fins to optimize thermal performance. This flexibility makes zipper fin heat sinks suitable for a wide range of applications, from small consumer electronics to high-power industrial equipment.

Applications of Zipper Fin Heat Sinks

Zipper fin heat sinks find applications in various industries where efficient heat dissipation is crucial. One common application is in computer hardware, such as central processing units (CPUs) and graphics processing units (GPUs). These components generate a significant amount of heat during operation, and zipper fin heat sinks help keep them cool, preventing performance issues and potential damage.

Another industry that benefits from zipper fin heat sinks is LED lighting. LEDs produce heat while emitting light, and excessive heat can degrade their performance and lifespan. By using zipper fin heat sinks, manufacturers can ensure optimal thermal management for LED lighting systems, improving their longevity and efficiency.

Zipper fin heat sinks are also utilized in power electronics, including inverters, motor drives, and power supplies. These devices often operate at high power levels, generating substantial heat. Effective heat dissipation is essential to maintain their reliability and prevent overheating, and zipper fin heat sinks provide an efficient cooling solution.

Conclusion

Zipper fin heat sinks offer a unique and effective solution for managing heat in electronic devices. Their innovative design, enhanced surface area, and excellent thermal conductivity properties make them highly suitable for various applications. Whether it's in computers, LED lighting, or power electronics, zipper fin heat sinks play a crucial role in maintaining optimal device performance and reliability.