Why Stamping Heat Sinks Are Widely Used?

Heat sinks play a crucial role in managing the heat generated by electronic devices, ensuring their optimal performance and longevity. Among the different types of heat sinks available in the market, stamping heat sinks have gained significant popularity. In this article, we will explore the reasons behind the widespread use of stamping heat sinks and their advantages in various applications. So, let's dive in and understand why stamping heat sinks are widely used.

1. Efficient Heat Dissipation

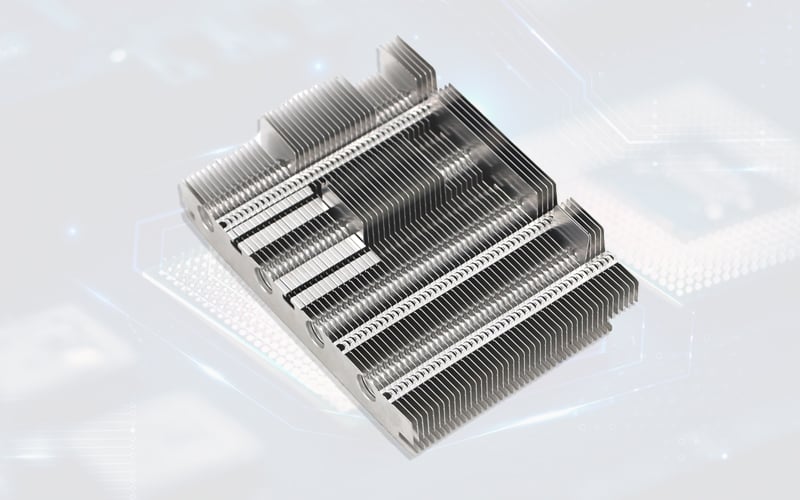

Stamping heat sinks are designed to efficiently dissipate heat generated by electronic components. The stamped fins, typically made of aluminum or copper, provide a large surface area for heat transfer. The increased surface area allows for better airflow and faster heat dissipation, ensuring that the electronic components stay within their operating temperature limits.

2. Cost-Effective Solution

Stamping heat sinks offer a cost-effective solution for heat management in electronic devices. The stamping process allows for mass production of heat sinks at a lower cost compared to other manufacturing methods. This makes stamping heat sinks an attractive choice for manufacturers looking to reduce production costs without compromising on performance.

3. Versatile Designs

Stamping heat sinks offer versatility in design, allowing manufacturers to customize the heat sinks according to the specific requirements of their electronic devices. The stamping process enables the creation of intricate and complex shapes, which can be tailored to fit within limited space constraints. This flexibility in design makes stamping heat sinks suitable for a wide range of applications.

4. Lightweight and Compact

Stamping heat sinks are typically lightweight and compact, making them ideal for applications where space and weight are critical factors. The stamped fins are thin and can be optimized for maximum heat dissipation while minimizing the overall weight and size of the heat sink. This makes stamping heat sinks particularly suitable for portable electronic devices such as laptops, smartphones, and tablets.

5. Enhanced Thermal Performance

Stamping heat sinks offer enhanced thermal performance compared to other types of heat sinks. The stamped fins create turbulence in the airflow, which improves heat transfer efficiency. Additionally, the large surface area of the fins allows for better contact with the surrounding air, facilitating faster heat dissipation. This results in improved thermal management and prevents overheating of electronic components.

6. Easy Integration

Stamping heat sinks are designed for easy integration into electronic devices. They can be attached to the components using various methods such as adhesive, clips, or screws. The ease of integration simplifies the manufacturing process and reduces assembly time. This makes stamping heat sinks a preferred choice for manufacturers looking for efficient and hassle-free heat management solutions.

7. Wide Range of Applications

Stamping heat sinks find applications in various industries and electronic devices. They are commonly used in computers, LED lighting, power supplies, automotive electronics, telecommunications equipment, and many other electronic devices. The versatility and effectiveness of stamping heat sinks make them suitable for a wide range of applications where heat dissipation is crucial.

8. Durability and Reliability

Stamping heat sinks are known for their durability and reliability. The stamped fins provide structural integrity to the heat sink, ensuring long-term performance without deformation or damage. The use of high-quality materials such as aluminum or copper further enhances the heat sink's durability and resistance to corrosion. This durability and reliability make stamping heat sinks a preferred choice for demanding applications.

9. Environmentally Friendly

Stamping heat sinks are environmentally friendly compared to other types of heat sinks. The stamping process generates minimal waste, and the materials used in the production are recyclable. Additionally, the efficient heat dissipation provided by stamping heat sinks can contribute to energy savings by reducing the need for active cooling systems. This makes stamping heat sinks a sustainable choice for heat management in electronic devices.

10. Wide Availability

Stamping heat sinks are widely available in the market, making them easily accessible for manufacturers and designers. The wide availability ensures that manufacturers can find suitable heat sink solutions for their specific requirements without facing supply chain challenges. The availability of stamping heat sinks in various sizes and configurations further adds to their appeal and widespread use.