Why heat sinks are used in electronic circuits?

Electronic circuits are everywhere, from smartphones to industrial machinery. They are the building blocks of modern technology, allowing us to process and transmit information at lightning speed. However, electronic devices generate heat, which can damage the components and reduce their lifespan. To prevent this, heat sinks are used in electronic circuits. In this article, we will discuss the function, types, and benefits of heat sinks.

Function of Heat Sinks

Heat sinks are designed to dissipate or transfer the heat generated by electronic circuits. When electrical current flows through a circuit, it causes the components to heat up. This heat can build up and cause the components to overheat, leading to malfunctions or even permanent damage.

A heat sink is a passive cooling system that provides a large surface area for heat to escape from the circuit. The heat produced by the components is transferred to the heat sink, which then radiates it into the surrounding air. Heat sinks can be made of different materials, such as aluminum, copper, or graphite. The choice of material depends on the specific application and the desired thermal performance.

Types of Heat Sinks

Heat sinks come in different shapes and sizes, depending on the requirements of the electronic circuit. The most common types of heat sinks are:

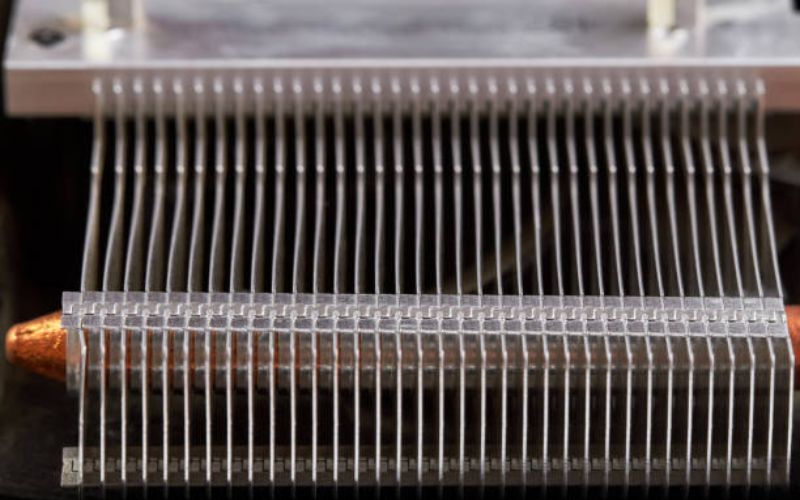

1. Finned Heat Sinks

Finned heat sinks are the most common type of heat sink. They have a series of fins that increase the surface area of the heat sink, allowing for more efficient heat dissipation. Finned heat sinks can be either passive or active. Passive heat sinks rely on natural convection to transfer heat, while active heat sinks use fans to increase airflow over the fins.

2. Plate Heat Sinks

Plate heat sinks are flat, rectangular heat sinks that are used in applications where space is limited. They are commonly used in laptop computers, where thin profile is essential. Plate heat sinks can be either extruded or stamped. Extruded plate heat sinks are made by forcing aluminum or copper through a die to create the desired shape. Stamped plate heat sinks are made by punching the desired shape out of a sheet metal.

3. Bonded Fin Heat Sinks

Bonded fin heat sinks are similar to finned heat sinks, but the fins are attached to the base of the heat sink with a bonding agent, such as epoxy or solder. This provides a more secure attachment than regular finned heat sinks and allows for better heat transfer.

4. Liquid Cooled Heat Sinks

Liquid cooled heat sinks are used in high-performance applications where passive or active cooling is not sufficient. They work by circulating a liquid, such as water or coolant, through the heat sink to absorb the heat. The hot liquid is then transferred to a radiator, where it is cooled before being recirculated.

Benefits of Heat Sinks

The benefits of using heat sinks in electronic circuits are numerous:

1. Increased Lifespan of Components

Heat sinks help prevent overheating of electronic components, which can lead to premature failure. By dissipating heat efficiently, heat sinks can significantly increase the lifespan of electronic components.

2. Improved Performance

Electronic circuits that run cooler tend to perform better than those that run hot. Heat sinks help keep the temperature of electronic components within acceptable limits, resulting in improved performance and reliability.

3. Cost Savings

By increasing the lifespan of electronic components, heat sinks can help reduce maintenance and replacement costs. Heat sinks also improve energy efficiency, which can result in lower power consumption and reduced operating costs.

4. Design Flexibility

Heat sinks come in many shapes and sizes, which allows for more flexibility in the design of electronic circuits. This flexibility can lead to more compact and efficient designs.

Conclusion

Heat sinks are an essential component of electronic circuits, providing a means for dissipating or transferring heat generated by electronic components. By choosing the right type of heat sink for the specific application, electronic devices can run cooler, last longer, and perform better. Whether it's a finned heat sink, a plate heat sink, or a liquid cooled heat sink, there's a heat sink that's right for your application.