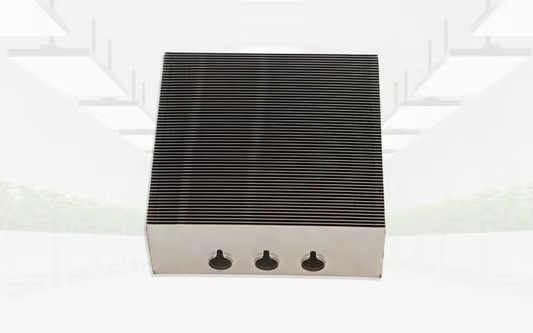

The Science Behind Metal Heat Sinks

Heat sinks play a crucial role in the cooling of electronic devices. These devices, such as computer processors and power amplifiers, generate a significant amount of heat during operation. To prevent overheating and subsequent damage, heat sinks are used to dissipate this heat efficiently. But Why are heat sinks made of metal?? Let's delve into the science behind this design choice.

1. Conductivity: Maximizing Heat Transfer

One of the primary reasons why heat sinks are made of metal is their high thermal conductivity. Metals, such as aluminum and copper, have excellent heat transfer properties. They conduct heat much better than other materials, such as plastics or ceramics. By using metal heat sinks, the heat generated by the electronic device can be efficiently transferred to the surrounding environment.

2. Material Compatibility: Matching Thermal Expansion

Another crucial aspect of heat sink design is matching the coefficient of thermal expansion (CTE) with that of the electronic component it is cooling. Electronic components, such as integrated circuits, can expand or contract with changes in temperature. By using a metal heat sink, which typically has a similar CTE to that of the component, any expansion or contraction can be accommodated without causing stress or damage.

3. Durability: Withstanding High Temperatures

Heat sinks are subjected to high temperatures during operation. Metal heat sinks, particularly those made of aluminum or copper, have excellent heat resistance properties. They can withstand the elevated temperatures without deforming or losing their effectiveness. This durability ensures that the heat sink remains functional over an extended period.

4. Cost-Effectiveness: Affordability and Availability

Metal heat sinks, especially those made of aluminum, are cost-effective solutions. Aluminum is abundant and relatively inexpensive compared to other materials. This cost-effectiveness makes it a popular choice for heat sink manufacturers, enabling them to produce efficient cooling solutions at a reasonable price.

5. Lightweight Design: Ease of Installation

Metal heat sinks, particularly those made of aluminum, offer a lightweight design. This characteristic makes them easy to handle and install, especially in applications where weight is a concern. The lightweight nature of metal heat sinks simplifies the assembly process and reduces the overall weight of the electronic device.

6. Corrosion Resistance: Protection Against Environmental Factors

Electronic devices, particularly those used in outdoor or harsh environments, are exposed to various elements that can cause corrosion. Metal heat sinks, such as those made of copper, are known for their excellent corrosion resistance properties. This resistance ensures that the heat sink remains effective and reliable even in challenging conditions.

7. Electrical Conductivity: Grounding and EMI Shielding

Metal heat sinks, besides their primary heat dissipation function, offer electrical conductivity benefits. The use of metal heat sinks allows for effective grounding of electronic components, reducing the risk of electrical shocks or interference. Additionally, metal heat sinks can provide electromagnetic interference (EMI) shielding, preventing unwanted signals from interfering with the device's operation.

8. Versatile Designs: Customization and Adaptability

Metal heat sinks offer a high level of versatility in terms of design and customization options. Manufacturers can easily mold or shape metals to fit specific electronic components, ensuring optimal heat transfer. This adaptability allows for the creation of heat sinks that cater to various form factors, sizes, and cooling requirements of different devices.

9. Eco-Friendliness: Recyclability and Sustainability

Metal heat sinks, particularly those made of aluminum or copper, are highly recyclable. Recycling these metals reduces the demand for new raw materials and minimizes environmental impact. Additionally, metal heat sinks can have a long lifespan, contributing to the overall sustainability of electronic devices by reducing waste and the need for frequent replacements.

10. Aesthetics: Sleek and Professional Appearance

While aesthetics may not be the primary consideration, metal heat sinks offer a sleek and professional appearance. Their shiny and polished surfaces can enhance the overall look of electronic devices, making them visually appealing. This aesthetic appeal is particularly important in consumer electronics or applications where appearance matters.