Understanding heat sink strips

Heat sink strips are used in electronic devices and serve as a cooling mechanism that dissipates heat generated by various components. They are thin strips typically made from copper or aluminum that are placed on top of integrated circuits to absorb heat. Heat sink strips are essential in preventing overheating, which can cause malfunctions or permanent damage to electronic devices.

The Benefits of Using Heat Sink Strips

There are several advantages to using heat sink strips in electronic devices. Firstly, they help to maintain the optimum operating temperature of the device, thus improving its performance. Secondly, heat sink strips can prolong the lifespan of electronic components by reducing the likelihood of overheating. Finally, heat sink strips can help save energy by ensuring that the device operates efficiently.

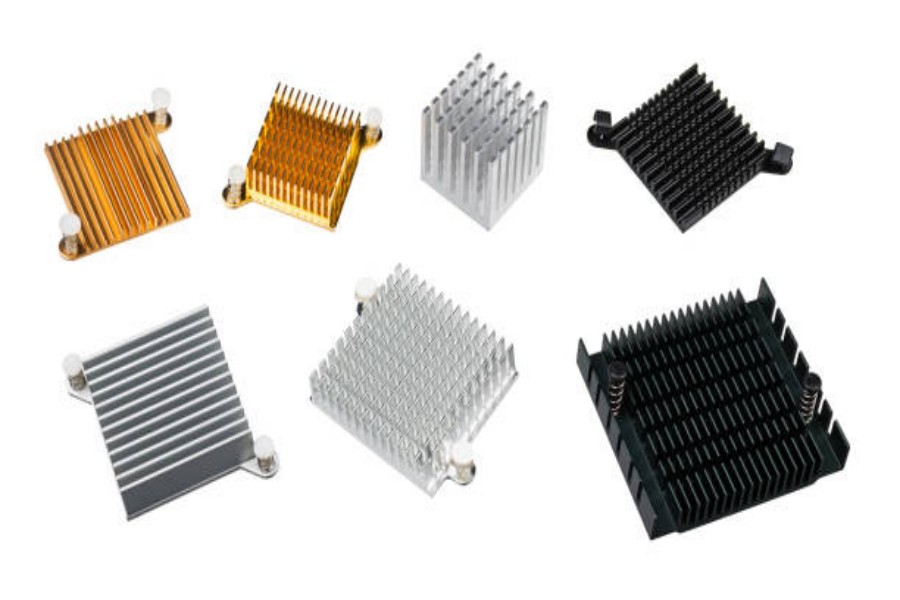

The Different Types of Heat Sink Strips

There are various types of heat sink strips available, each designed with different specifications to suit specific applications. Passive heat sink strips are made of solid metal and rely on natural convection for heat dissipation. Active heat sink strips, on the other hand, use fans or pumps to actively circulate air or water to cool down components. Hybrid heat sink strips combine features of both passive and active heat sink strips to provide the best of both worlds.

The Role of Heat Sink Compound

Heat sink compound, also known as thermal paste, is used to increase the contact between the heat sink strip and the electronic component. This helps to improve heat transfer between the two surfaces, resulting in more effective cooling. Heat sink compound is applied to the surface of the electronic component before placing the heat sink strip on top of it.

Considerations When Choosing a Heat Sink Strip

When selecting a heat sink strip, it is important to consider the size and shape of the electronic component, as well as the amount of heat being generated. The heat sink strip should also be made of a material that has good thermal conductivity properties, such as copper or aluminum. The type of heat sink strip should match the specific application, such as passive or active cooling.

Installation of Heat Sink Strips

Proper installation of heat sink strips is crucial for effective cooling. It is important to ensure that the heat sink strip is in full contact with the electronic component and that the thermal paste has been evenly applied. The heat sink strip should also be mounted securely to prevent vibration or movement from affecting its performance.

Common Issues with Heat Sink Strips

One of the common problems with heat sink strips is insufficient thermal paste, which can result in poor heat transfer and reduced cooling efficiency. Another issue is the tendency of heat sink strips to clog with dust or debris, which can also impact cooling performance. It is important to regularly clean heat sink strips to prevent clogging.

Factors Affecting Heat Sink Strip Performance

Several factors can affect the performance of heat sink strips, including the ambient temperature of the environment and the amount of airflow around the device. The power consumption of the electronic component can also impact heat generation and cooling requirements. Proper design and selection of heat sink strips can ensure optimal performance under various conditions.

Applications of Heat Sink Strips

Heat sink strips are used in a wide range of electronic devices, including personal computers, servers, and gaming consoles. They are also commonly used in LED lighting and power supply units for electronic devices. Heat sink strips are essential in ensuring the efficient and reliable operation of electronic components.

Conclusion

Heat sink strips are an important component in maintaining the optimal operating temperature of electronic devices. Understanding the different types of heat sink strips and the factors that affect their performance is crucial in selecting the most appropriate type for a specific application. Proper installation and maintenance of heat sink strips can prevent overheating and ensure the efficient and reliable operation of electronic devices.