The Purpose of Aluminum Heat Sinks

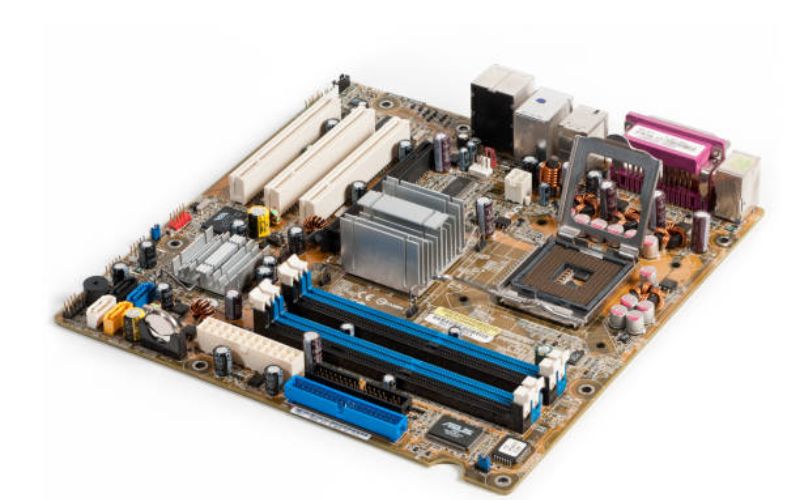

Aluminum heat sinks are commonly used in electronic devices to regulate and dissipate heat. Heat sinks are designed to transfer heat away from a heat-generating component, such as a microprocessor, and distribute it throughout the heat sink before dissipating it into the air. This process helps to maintain a safe operating temperature, preventing electronic devices from becoming damaged or malfunctioning due to overheating.

Why is Aluminum the Preferred Material?

While there are several materials that can be used to manufacture heat sinks, aluminum is the most commonly used material. This is because aluminum offers several advantages over other materials. Aluminum is lightweight, easy to machine, and has excellent thermal conductivity. In addition, it is relatively inexpensive, making it a cost-effective option for manufacturers.

What Type of Aluminum is Used?

The most common type of aluminum used for heat sinks is extruded aluminum. Extruded aluminum is produced by pushing heated aluminum through a die to form a specific shape. This process creates strong, lightweight aluminum heat sinks that are ideal for use in electronic devices. In addition, the extrusion process can be customized to create heat sinks with specific shapes and sizes to suit a variety of applications.

Aluminum Alloys Used in Heat Sinks

Heat sinks are often made from aluminum alloys, which are mixtures of aluminum and other metals. The most commonly used aluminum alloys for heat sinks are 6061 and 6063. These alloys have excellent thermal conductivity and can be easily extruded into complex shapes. In addition, they offer good corrosion resistance and can be anodized to enhance their durability and appearance.

Other Metals Used in Heat Sinks

While aluminum is the preferred material for heat sinks, other metals can also be used. Copper is an excellent heat conductor and is often used in high-performance heat sinks. However, copper is heavier and more expensive than aluminum, making it less common in consumer electronics. Other metals that can be used in heat sinks include silver, gold, and diamond. However, these metals are much more expensive and are typically only used in specialized applications.

Manufacturing Processes for Aluminum Heat Sinks

There are several manufacturing processes that can be used to produce aluminum heat sinks. The most common method is extrusion. This process involves heating the aluminum to a specific temperature and then forcing it through a die to create the desired shape. Another method is skiving, which involves cutting fins into a solid block of aluminum using a specialized cutting tool. Lastly, casting is a method of producing heat sinks that involves pouring molten aluminum into a mold and allowing it to cool and solidify.

Factors that Affect Heat Sink Performance

Several factors can impact the performance of an aluminum heat sink, including its size, shape, surface area, and the airflow around it. Heat sinks that have a larger surface area and greater mass will generally have better heat dissipation capabilities. The shape of the heat sink can also impact its performance, as fins and other features that increase the surface area can improve heat dissipation. Finally, airflow around the heat sink is critical, as it helps to transfer the heat away from the heat-generating component and into the heat sink.

Applications of Aluminum Heat Sinks

Aluminum heat sinks are commonly used in a wide range of electronic devices, including computers, televisions, and mobile phones. They are also used in industrial applications, such as power supplies and motor drives. In addition, they are used in automotive applications to manage the heat generated by the engine and transmission.

The Environmental Impact of Aluminum Heat Sinks

Aluminum is a fully recyclable material, making aluminum heat sinks an eco-friendly option. In addition, the extrusion process used to manufacture aluminum heat sinks is energy-efficient, as it requires less energy than other manufacturing processes. This helps to reduce the environmental impact of aluminum heat sinks.

Conclusion - Aluminum Heat Sinks

Aluminum heat sinks are an essential component in electronic devices, helping to regulate and dissipate heat to prevent damage and malfunctioning. Aluminum's excellent thermal conductivity and lightweight properties make it an ideal material for heat sinks. In addition, extrusion allows for customization and mass production. Finally, aluminum is an environmentally-friendly material that can be recycled and requires less energy to produce than other manufacturing processes.