Understanding Heat Sinks

A heat sink is an electronic device that absorbs and dissipates heat generated by electronic components such as computer processors and power transistors. Heat sinks are made up of materials such as aluminum or copper, and are available in various sizes and shapes to suit different electronic devices. For a heat sink to function optimally, it must not exceed a particular temperature. In this article, we will discuss the maximum temperature for a heat sink and factors that affect its performance.

Factors That Affect Heat Sink Performance

The maximum temperature for a heat sink is influenced by several factors. One of the key factors that affect heat sink performance is the material used to manufacture it. Heat sinks made of copper material, for example, have high thermal conductivity and heat absorption. Other notable materials used in making heat sinks include aluminum, brass, and ceramic.

Thermal Resistance and Maximum Temperature

Heat sink performance is also determined by its thermal resistance, which is defined as the measure of how well the heat sink conducts heat away from the electronic component. To achieve optimal performance, heat sinks must maintain low thermal resistance. The maximum temperature that a heat sink can operate at is mainly determined by its thermal design power, the thermal resistance of the system, and the ambient temperature.

The Relationship Between Heat Sink Size and Maximum Temperature

Heat sink size plays a critical role in its performance. In general, larger heat sinks have more surface area, which enables them to dissipate more heat. Smaller heat sinks, on the other hand, are often used in portable devices like laptops and smartphones where space is limited. The maximum temperature that a heat sink can handle is proportional to its size. Larger heat sinks can handle higher temperatures compared to smaller ones.

The Effect of Airflow on Heat Sink Performance

Airflow is also a critical factor in heat sink performance. Airflow helps to remove the heat that the heat sink has absorbed from the electronic component, thereby reducing its temperature. Greater airflow generally means a more effective removal of heat. Heat sinks are designed to work with specific airflow conditions, and changing the airflow can affect their performance. If the ambient temperature increases, the heat sink will require more airflow to maintain its rated temperature.

The Impact of Thermal Interface Material

Thermal interface material (TIM) is a material used to ensure good contact between heat sinks and electronic components. TIM increases thermal conductivity between the two surfaces, which results in lower thermal resistance. The choice and application of TIMs can significantly affect heat sink performance. Quality thermal interface materials can reduce thermal resistance, increasing the heat sink's maximum temperature.

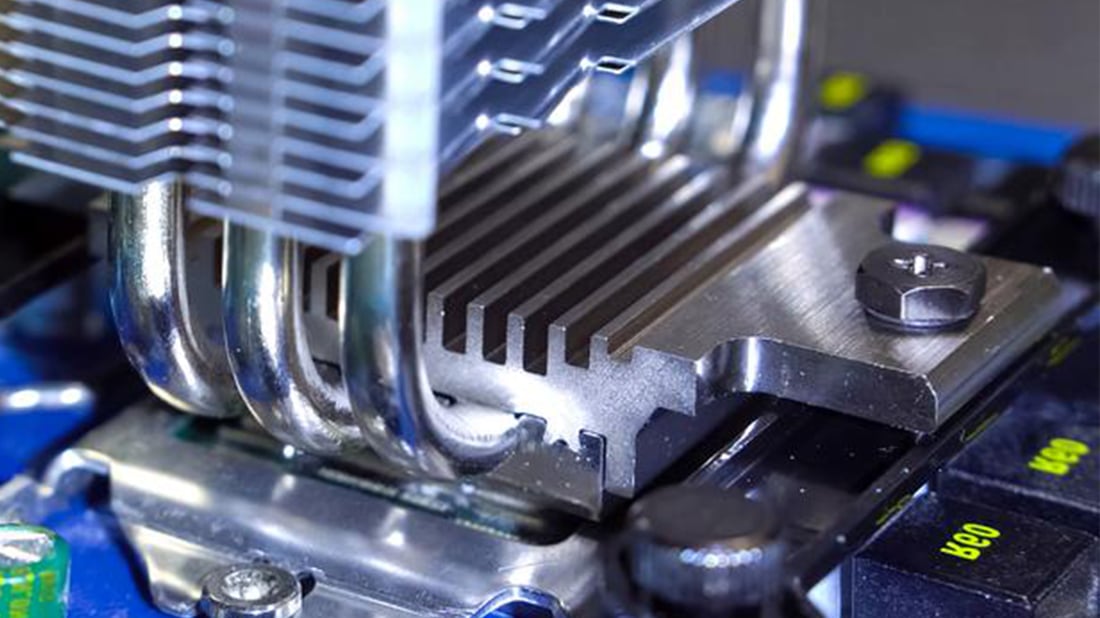

Heat Sink Mounting Systems

Heat sink mounting systems also play a crucial role in their performance. Mounting systems should be properly designed and stable enough to provide uniform contact pressure and avoid hot spots that can hinder performance. Effective mounting systems ensure proper contact with the electronic component for efficient heat dissipation.

The Effect of Overclocking on Heat Sink Temperature

Overclocking is the process of running the electronic component at higher frequencies or voltages than the manufacturer's recommended values. Overclocking requires more power and results in increased heat production. This can lead to high temperature buildup on the heat sink and shorten its lifespan. When overclocking, the maximum temperature that a heat sink can handle should be taken into consideration to prevent damage.

The Conclusion

In conclusion, the maximum temperature that a heat sink can handle is determined by a combination of factors such as material, size, thermal resistance, thermal interface material, and ambient temperature. Proper design, installation, and maintenance of the heat sink can significantly improve its performance and prolong its lifespan.