Importance of the Fin Gap

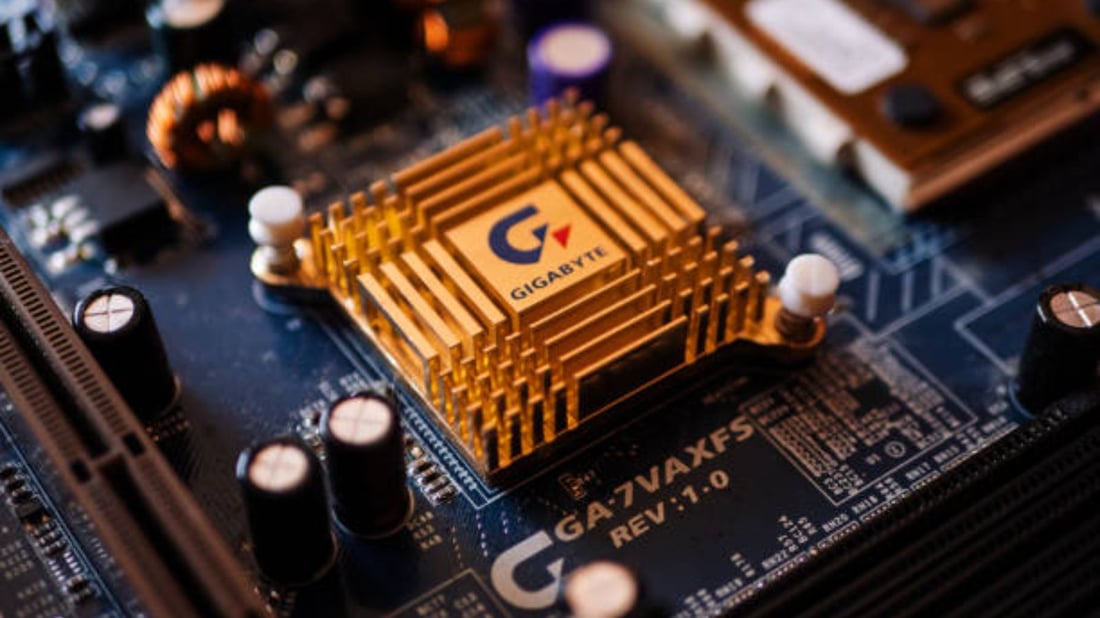

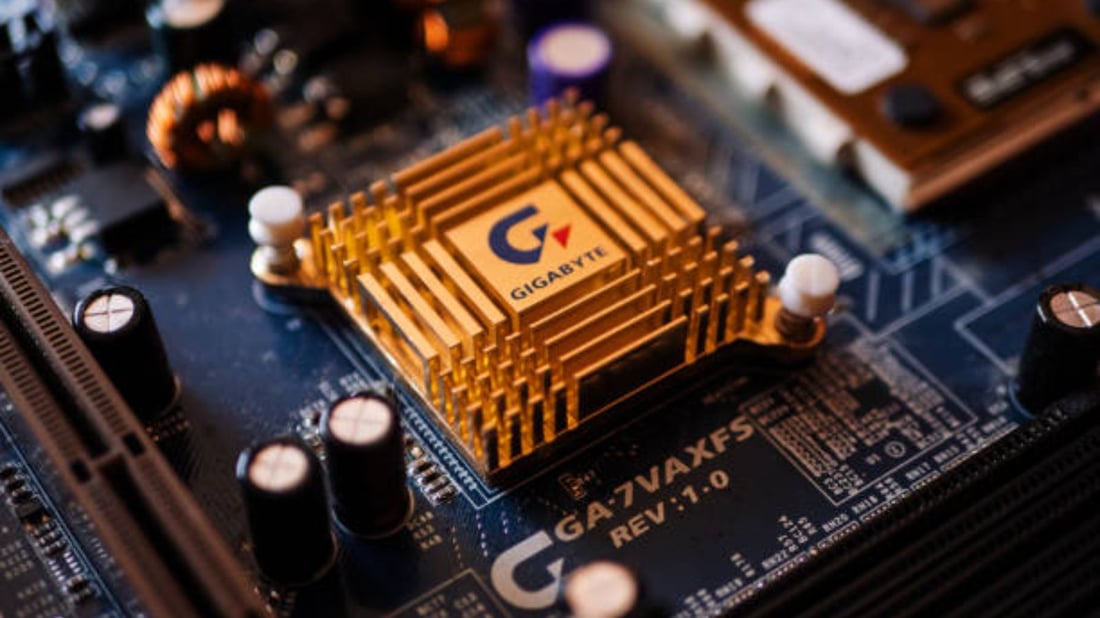

When it comes to optimizing the performance of a heatsink, one crucial factor to consider is the fin gap. The fin gap refers to the distance between the fins on the heatsink. This gap plays a vital role in determining how efficiently heat can be dissipated from the heatsink. A smaller fin gap can lead to better thermal conductivity, while a larger fin gap may compromise the heatsink's ability to cool effectively.

Effect on Heat Dissipation

The fin gap directly impacts the surface area available for heat dissipation. A smaller fin gap means more fins can be packed onto the heatsink, increasing the surface area exposed to the airflow. This allows for better heat transfer from the heatsink to the surrounding air. On the other hand, a larger fin gap reduces the surface area, limiting the heat dissipation capacity of the heatsink.

Optimal Fin Gap Size

Finding the optimal fin gap size for a heatsink involves striking a balance between maximizing surface area and maintaining structural integrity. In general, a fin gap of 0.5 to 1.5 mm is considered ideal for most heatsink applications. However, the specific requirements may vary depending on the heat load, airflow, and material of the heatsink.

Thermal Resistance Considerations

The fin gap also influences the thermal resistance of the heatsink. A smaller fin gap reduces thermal resistance by allowing for better heat conduction through the fins. This can result in lower operating temperatures for the components being cooled. Conversely, a larger fin gap increases thermal resistance, leading to higher temperatures and reduced cooling efficiency.

Impact on Airflow

The fin gap can significantly impact the airflow through the heatsink. A smaller fin gap creates more resistance to airflow, which can increase turbulence and improve heat dissipation. On the other hand, a larger fin gap may allow air to bypass the fins, reducing the cooling efficiency of the heatsink. It is essential to strike a balance between airflow resistance and heat dissipation when designing a heatsink.

Material Compatibility

The choice of material for the heatsink can also influence the optimal fin gap size. Different materials have varying thermal conductivities and heat dissipation properties. For example, aluminum heatsinks typically have smaller fin gaps due to their excellent thermal conductivity, while copper heatsinks may require a slightly larger fin gap to achieve optimal cooling performance.

Manufacturing Considerations

When designing a heatsink, manufacturers must consider the practical limitations of fin gap size. Smaller fin gaps may be challenging to manufacture, requiring precise machining or assembly processes. On the other hand, larger fin gaps can lead to structural weaknesses in the heatsink. Finding the right balance between manufacturability and performance is crucial in heatsink design.

Customization Options

For applications with specific cooling requirements, custom heatsinks can be designed with tailored fin gap sizes. By adjusting the fin gap based on the heat load, airflow conditions, and space constraints, engineers can optimize the heatsink's performance for a particular application. Customization allows for fine-tuning the thermal management system to meet the exact needs of the electronic components.

Thermal Management Solutions

In today's electronics industry, efficient thermal management is essential to ensure the reliability and longevity of electronic devices. Heatsinks play a critical role in dissipating heat generated by electronic components. Understanding the significance of the fin gap in heatsink design is key to developing effective thermal management solutions that meet the cooling requirements of modern electronics.

Conclusion

In conclusion, the fin gap is a fundamental aspect of heatsink design that influences heat dissipation, thermal resistance, airflow, material compatibility, and manufacturing considerations. By carefully selecting the fin gap size based on the requirements of the application, engineers can optimize the performance of heatsinks and enhance the thermal management of electronic devices.

Quote Inquiry

Contact us!