Introduction

Heat management in electronic devices and computers is a critical issue that many manufacturers have to address. The generation of heat by various components of such devices affects their performance, lifespan, and can sometimes lead to potential damage or safety hazards. The two main solutions used in heat management are heat sinks and vapor chambers. In this article, we will go through each of these to understand the difference between them.

What is a Heat Sink?

A heat sink is a passive device designed to dissipate excess heat generated by electronic components such as CPUs, GPUs, and other ICs. Heat sinks consist of a metal base (usually copper or aluminum) with fins which increases its surface area. The metal base is mounted on the electronic component whereas the fins are exposed to the air for cooling. The air then carries away the heat from the heat sink. The performance of a heat sink depends on factors such as its surface area, the material used, and contact between the heat source and the sink.

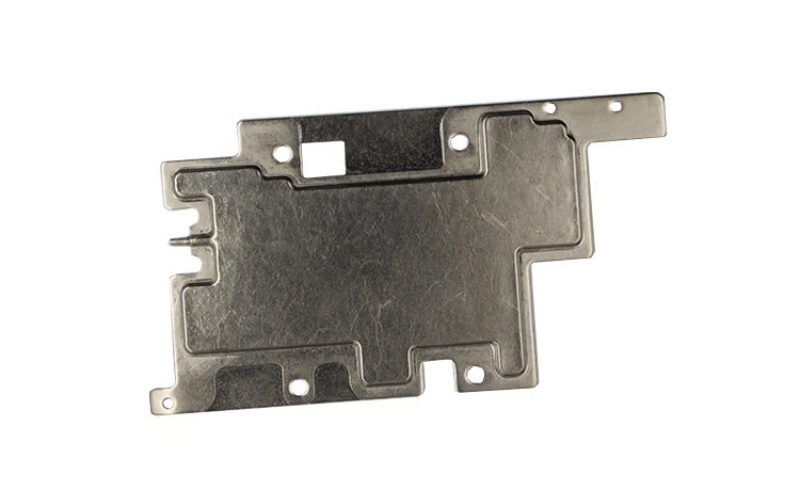

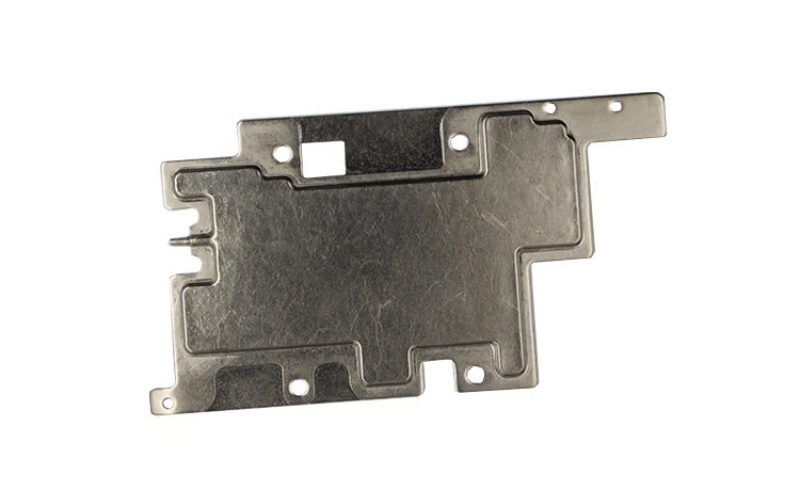

What is a Vapor Chamber?

A vapor chamber is a flat, metal plate that utilizes the principles of phase change to transfer heat. A vapor chamber consists of two flat plates sealed together with a small gap that contains a liquid (usually water) that boils when heated. As the liquid boils, it vaporizes and fills the gap, absorbing heat from one of the plates. The vapor then condenses to liquid again, releasing the heat to the other plate. The process then repeats, facilitating a high amount of heat transfer with minimal temperature gradients.

Performance Difference

Heat sinks are generally used for small devices which generate less heat. They can dissipate moderate amounts of heat from a single component, but their effectiveness diminishes when used in configurations with high power density. Vapor chambers, on the other hand, are more effective in dissipating high amounts of heat from multiple sources. They are used in advanced electronic devices that require a more efficient cooling system, such as high-end graphics cards and servers.

Design and Structure

Heat sinks have a simple design and a structure consisting of fins which increases their surface area. They are easy to install, and their design can be customized to suit specific applications. However, they are limited by the amount of heat they can dissipate and require proper airflow to achieve optimal performance. Vapor chambers are more complex in design and structure, incorporating multiple chambers in a single sheet of metal. They require an intricate manufacturing process, and their design is not easily customisable.

Airflow Requirement

Heat sinks require the flow of air over their fins to remove heat efficiently. They need to be positioned in a position that facilitated proper airflow, such as vertically. In contrast, vapor chambers require no external airflow. They can be used in any position since they operate independently of air convection.

Size and Weight

When it comes to size and weight, heat sinks are generally bulkier and heavier than vapor chambers. Heat sinks with greater surface area are required to dissipate more heat. Larger heat sinks can be challenging to incorporate into designs of small electronic devices. Conversely, vapor chambers have smaller footprints because they are thinner and have less volume.

Noise Level

Heat sinks operate without the need of power and hence generate no noise. On the other hand, vapor chambers require power to operate the pump that moves the coolant from one part of the plate to the other. The pump creates some level of noise.

Cost

Heat sinks are inexpensive to manufacture due to their simplicity in design and structure. Conversely, vapor chambers are more expensive to manufacture and are typically used in high-end electronic devices due to their high-performance capabilities.

Environmental Impact

Vapor chambers have a more considerable environmental impact than heat sinks. Since they require electricity to operate, they contribute more to carbon emissions. In contrast, heat sinks are passive devices that do not require electricity.

Conclusion

Heat sinks and vapor chambers are effective cooling solutions used in modern electronic devices to improve their performance and reliability. Heat sinks are more suitable for small devices that generate lower amounts of heat, while vapor chambers are more effective in dissipating high amounts of heat from multiple sources. Selecting the best cooling solution for electronic devices will depend on various factors such as the design, power, performance, and cost.

heat sink, vapor chamber, cooling, electronic devices, performance, design, airflow, size, weight, cost

What is the difference between a heat sink and a vapor chamber?? - A Comprehensive Guide

Looking for a comprehensive guide on the difference between a heat sink and a vapor chamber? Read on to understand their design, performance, and suitability for electronic devices.

Quote Inquiry

Contact us!