What is the best aluminum alloy for a heat sink?

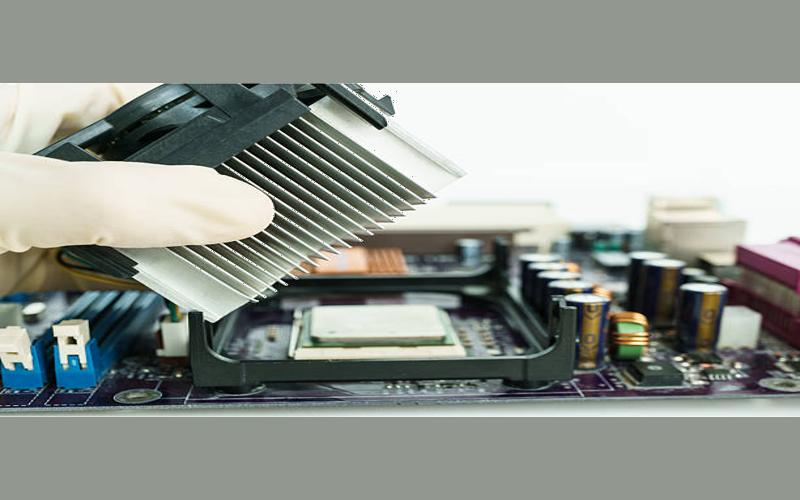

Heat sinks are essential components in electronic devices that help dissipate heat and maintain optimal operating temperatures. Aluminum alloys are commonly used for heat sink manufacturing due to their excellent thermal conductivity and lightweight properties. However, not all aluminum alloys are created equal when it comes to heat sink applications. In this article, we will explore the best aluminum alloy options for a heat sink, considering factors such as thermal conductivity, cost-effectiveness, and availability.

1. Understanding the Importance of Thermal Conductivity

Thermal conductivity is a critical parameter when selecting an aluminum alloy for a heat sink. It measures how well a material can transfer heat. The higher the thermal conductivity, the better the heat dissipation capabilities of the alloy. Among the various aluminum alloys available, 6063 and 6061 are the most popular choices due to their high thermal conductivity values.

2. 6063 Aluminum Alloy: The Ideal Choice for Extruded Heat Sinks

6063 aluminum alloy is widely used in extruded heat sinks due to its excellent thermal conductivity, good corrosion resistance, and ease of extrusion. It offers a thermal conductivity of approximately 201-218 W/m·K, making it an ideal choice for applications where efficient heat dissipation is crucial, such as in computer CPUs and LED lighting systems.

3. 6061 Aluminum Alloy: A Versatile Option for Heat Sinks

Similar to 6063, 6061 aluminum alloy is also widely used in heat sink manufacturing. It possesses good thermal conductivity (167 W/m·K), high strength, and excellent machinability. Heat sinks made from 6061 aluminum alloy can be found in various applications, including power transistors, audio amplifiers, and motor controllers.

4. 1100 Aluminum Alloy: A Cost-Effective Solution

While not as thermally conductive as 6063 or 6061, 1100 aluminum alloy offers a more cost-effective solution for heat sink applications. It has a thermal conductivity of around 218 W/m·K, making it suitable for low-power electronic devices or situations where budget constraints are a factor.

5. 3003 Aluminum Alloy: A Balance Between Cost and Performance

3003 aluminum alloy strikes a good balance between cost and performance. With a thermal conductivity of about 160 W/m·K, it is a reliable choice for heat sink applications in consumer electronics, automotive components, and industrial machinery.

6. 5083 Aluminum Alloy: Enhanced Corrosion Resistance

In certain environments where heat sinks may be exposed to corrosive elements, 5083 aluminum alloy provides an excellent solution. While its thermal conductivity is lower than the previously mentioned alloys (around 147 W/m·K), its exceptional corrosion resistance makes it suitable for marine or outdoor applications.

7. 7075 Aluminum Alloy: High Strength and Temperature Resistance

For heat sink applications that require both excellent thermal conductivity and high strength, 7075 aluminum alloy is a top choice. Although its thermal conductivity is lower than other options (around 130 W/m·K), its superior strength and temperature resistance make it suitable for aerospace, military, and high-performance computing applications.

8. Availability and Cost Considerations

When selecting the best aluminum alloy for a heat sink, it is essential to consider both availability and cost. While certain alloys may offer superior thermal conductivity, they might be more expensive or less readily available. Balancing performance requirements with practical considerations is crucial to ensure the feasibility and cost-effectiveness of heat sink production.

9. Other Factors to Consider

In addition to thermal conductivity, cost, and availability, other factors to consider when choosing an aluminum alloy for a heat sink include mechanical properties, machinability, solderability, and compatibility with manufacturing processes. It is essential to assess these factors holistically and select the alloy that best meets the specific needs of the heat sink application.

10. Conclusion

When it comes to selecting the best aluminum alloy for a heat sink, there are several options to consider, each with its own set of advantages and limitations. The choice ultimately depends on the specific requirements of the application, including thermal conductivity, cost, availability, and environmental factors. By understanding the properties and characteristics of different aluminum alloys, engineers and designers can make informed decisions to ensure optimal heat dissipation and overall performance of their electronic devices.